Recycle system for recycled water

A technology for reclaimed water and sewage, applied in the direction of neutralized water/sewage treatment, water/sewage treatment, mining wastewater treatment, etc., can solve the problems of reverse osmosis membrane being easily blocked, high SS content, unusable, etc., and achieve turbidity High, high SS content, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

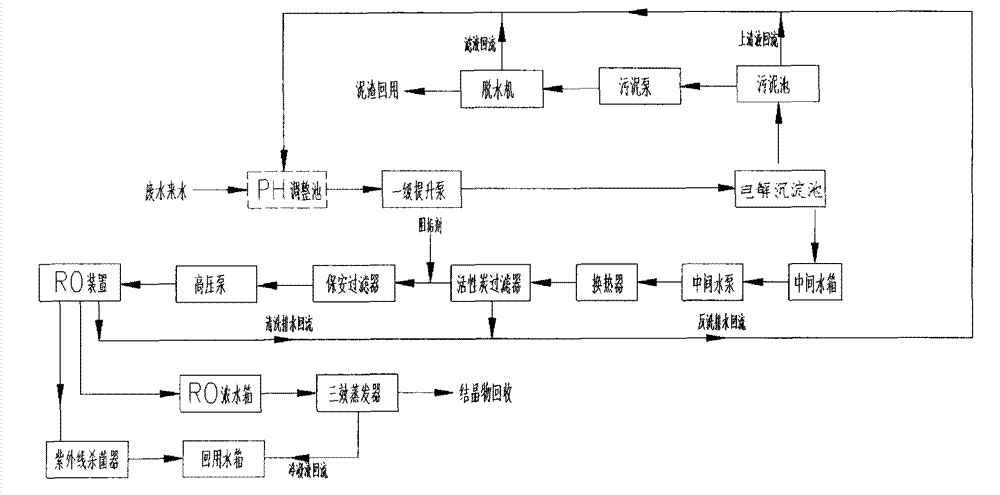

Image

Examples

Embodiment 1

[0021] The influent water to be treated is a copper mine beneficiation wastewater, and its water quality is as follows: pH: 11.5, Cu 284mg / L, Pb 6.6mg / L, COD 410mg / L, turbidity 115NTU, SS 1200mg / L.

[0022] The incoming water first enters the pH adjustment tank, and uses hydrochloric acid (HCl) to adjust the pH value of the sewage to about 7.2. The water then enters the electrolytic precipitation tank, which uses aluminum as the anode and steel as the cathode. And a magnetic field with a magnetic induction strength of 2500 Gauss is applied in a direction parallel to the electrode surface. The water entering the electrolytic precipitation tank stays in the tank for 30 minutes, the supernatant enters the next processing unit, and the sludge is discharged to the sludge tank, where it is washed, dehydrated, etc., and finally the sludge is recycled.

[0023] The supernatant liquid discharged from the electrolytic precipitation tank enters the heat exchange device through the inter...

Embodiment 2

[0030] The influent water to be treated is a copper mine beneficiation wastewater, and its water quality is as follows: pH: 12.1, Cu 220mg / L, Pb 8.5mg / L, COD 435mg / L, turbidity 100NTU, SS 1100mg / L.

[0031] The incoming water first enters the pH adjustment tank, and uses hydrochloric acid (HCl) to adjust the pH value of the sewage to about 7.2. The water then enters the electrolytic precipitation tank, which uses iron as the anode and steel as the cathode. And a magnetic field with a magnetic induction strength of 2500 Gauss is applied in a direction parallel to the electrode surface. The water entering the electrolytic precipitation tank stays in the tank for 30 minutes, the supernatant enters the next processing unit, and the sludge is discharged to the sludge tank, where it is washed, dehydrated, etc., and finally the sludge is recycled.

[0032] The supernatant liquid discharged from the electrolytic precipitation tank enters the heat exchange device through the intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com