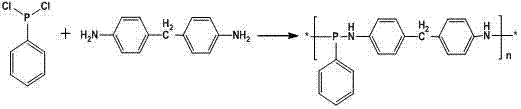

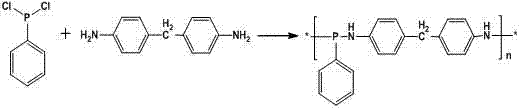

Synthetic method of phosphorus-nitrogen intumescent flame retardant

A technology of intumescent flame retardant and synthesis method, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the problems of poor flame retardant efficiency, difficult synthesis process, and compatibility In order to avoid problems such as poor stability, achieve the effects of high product purity and yield, simple post-treatment process, and simple production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add phenylphosphorous dichloride (8.950g, 0.05mol) and 100ml chloroform to a 250ml four-neck flask equipped with a thermometer, nitrogen gas introduction, 100ml constant pressure dropping funnel, magneton, reflux condenser and tail gas absorption device. 4,4'-Diaminodiphenylmethane (9.913g, 0.05mol) was dissolved in 50ml of chloroform and added to the constant pressure funnel. Under nitrogen protection and stirring, the 4,4'-diaminodiphenylmethane solution was slowly added dropwise. After the dropwise addition, the temperature was raised to the reflux temperature to continue the reaction for 4 hours, and the N was continued after the reaction was completed. 2 Bring to room temperature. Then the mixture was suction-filtered under reduced pressure, and the filter cake was washed with 100 ml of chloroform, and vacuum-dried at 100° C. for 6 hours to obtain 11.51 g of a light yellow solid with a yield of 75.6%.

Embodiment 2

[0022] Add phenyl phosphorus dichloride (8.950g, 0.05mol) and 100ml dichloromethane to a 250ml four-neck flask equipped with a thermometer, nitrogen gas introduction, 100ml constant pressure dropping funnel, magneton, reflux condenser and tail gas absorption device , 4,4'-diaminodiphenylmethane (9.913g, 0.05mol) was dissolved in 50ml of dichloromethane, and added to a constant pressure funnel. Under nitrogen protection and stirring, the 4,4'-diaminodiphenylmethane solution was slowly added dropwise. After the dropwise addition, the temperature was raised to the reflux temperature to continue the reaction for 4 hours, and the N was continued after the reaction was completed. 2 Bring to room temperature. Then the mixture was suction-filtered under reduced pressure, and the filter cake was washed with 100 ml of dichloromethane, and vacuum-dried at 100° C. for 6 hours to obtain 12.04 g of a light yellow solid with a yield of 79.1%.

Embodiment 3

[0024] Add phenyl phosphorus dichloride (26.85g, 0.15mol) and 200ml ethyl acetate to a 500ml four-neck flask equipped with a thermometer, nitrogen gas introduction, 100ml constant pressure dropping funnel, magneton, reflux condenser and tail gas absorption device , Dissolve 4,4'-diaminodiphenylmethane (29.74 g, 0.15 mol) in 100 ml ethyl acetate, and add it to a constant pressure funnel. Under nitrogen protection and stirring, the 4,4'-diaminodiphenylmethane solution was slowly added dropwise. After the dropwise addition, the temperature was raised to the reflux temperature to continue the reaction for 4 hours, and the N was continued after the reaction was completed. 2 Bring to room temperature. Then the mixture was suction-filtered under reduced pressure, and the filter cake was washed with 200 ml of ethyl acetate, and vacuum-dried at 100° C. for 6 hours to obtain 38.57 g of a light yellow solid with a yield of 84.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com