Gd-Mn-based amorphous magnetic refrigeration material and preparation method thereof

A magnetic refrigeration material, gd-mn technology, applied in the field of Gd-Mn-based amorphous magnetic refrigeration materials and its preparation, can solve the problems of poor corrosion resistance, low mechanical strength, narrow transition temperature range, etc., and achieve cost reduction and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

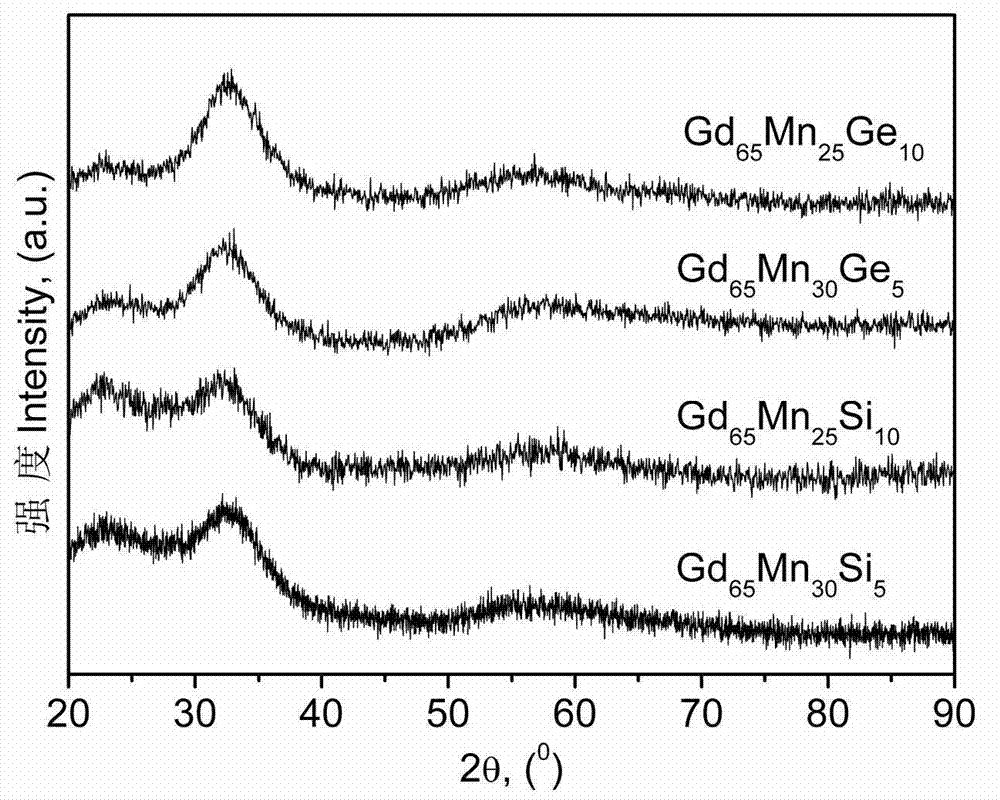

[0026] A preparation method of a Gd-Mn based amorphous magnetic refrigeration material is as follows:

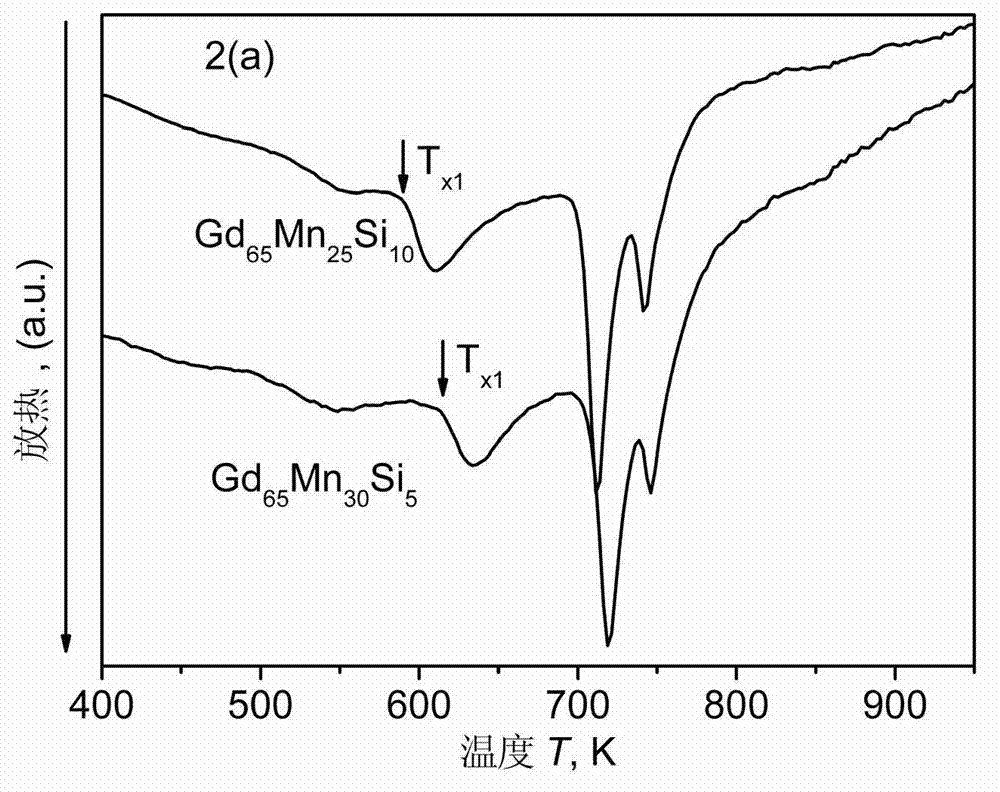

[0027] Step 1: Pure elements Gd, Mn and Si according to Gd 65 mn 35-x Si x The mass percentage of each element in (x=5,10) is weighed and mixed, and the nominal total weight of the sample is 10g;

[0028] Step 2: Put the above-mentioned prepared raw materials into a vacuum electric arc furnace, use a sponge Ti to absorb the atmosphere crucible, and evacuate low vacuum and high vacuum to 4.0×10 -3 Pa, use high-purity argon to clean the furnace, fill it with high-purity argon of about -0.02MPa as a protective gas, repeat the melting for 5 times, and obtain a button-shaped ingot with uniform composition after cooling;

[0029] Step 3: Break the smelted ingot, put it into a quartz tube, use induction melting, and vacuumize to 8.0×10 -4 Pa, the furnace is cleaned with high-purity argon, and argon is used as a protective gas. The tangential linear velocity of the copper roller...

Embodiment 2

[0036] A Gd-Mn based amorphous magnetic refrigeration material, the preparation method of which is as follows:

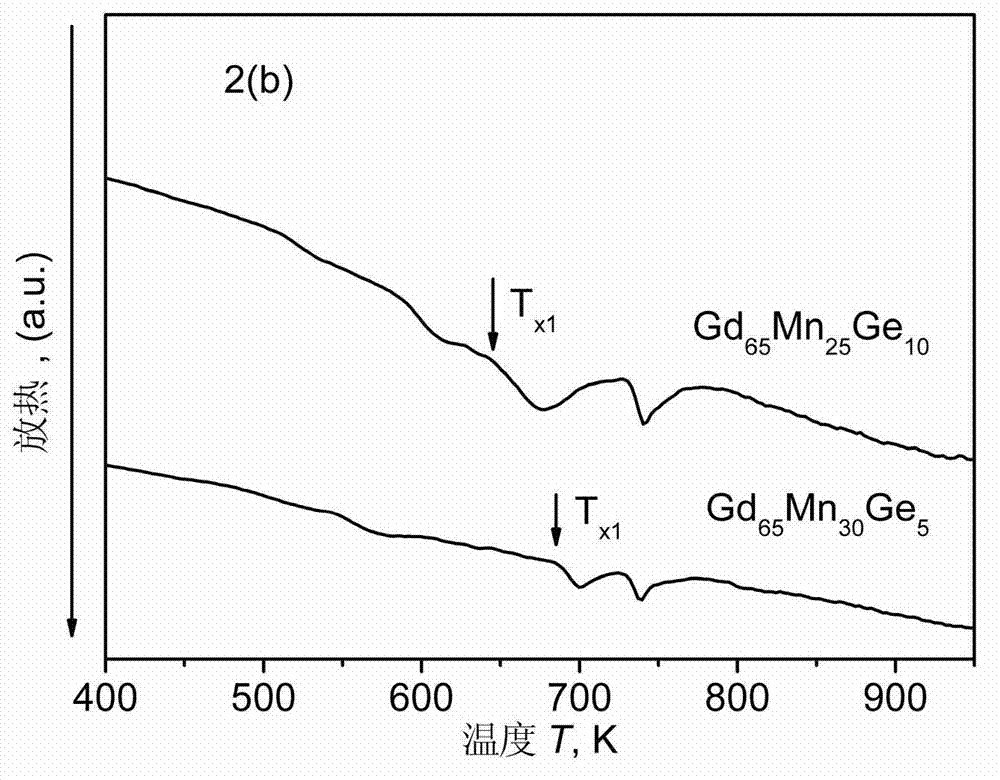

[0037] Step 1: Put pure elements Gd, Mn and Ge according to Gd 65 mn 35-x Ge x The mass percentage of each element in (x=5,10) is weighed and mixed, and the nominal total weight of the sample is 10g;

[0038] Step 2: Put the above-mentioned prepared raw materials into a vacuum electric arc furnace, use a sponge Ti to absorb the atmosphere crucible, and evacuate low vacuum and high vacuum to 4.0×10 -3 Pa, use high-purity argon to clean the furnace, fill it with high-purity argon of about -0.02MPa as a protective gas, repeat the melting for 5 times, and obtain a button-shaped ingot with uniform composition after cooling;

[0039] Step 3: Break the smelted ingot, put it into a quartz tube, use induction melting, and vacuumize to 8.0×10 -4 Pa, use high-purity argon to clean the furnace, and use argon as a protective gas, the tangential linear velocity of the copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com