High hydrogen response polyolefin catalyst component and preparation method thereof, and olefin polymerization method

An olefin polymerization and sensitive technology, applied in the field of olefin polymerization, can solve problems such as narrow molecular weight distribution and poor processability of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the normal-pressure reaction kettle repeatedly replaced by high-purity nitrogen, 4.8 grams of anhydrous magnesium chloride, 70 milliliters of toluene, 4.0 milliliters of epichlorohydrin, 12.5 milliliters of tributyl phosphate and 2.0 milliliters of tetraethoxysilane were added successively. Under the condition of 60 DEG C, reacted for 1 hour, added 1.4 grams of phthalic anhydride and 30 milliliters of toluene, continued to react for one hour, cooled to -28 DEG C, added dropwise 56 milliliters of titanium tetrachloride (drop speed 5 milliliters / min ), gradually warming up to 85°C (heating rate is 5°C / min), constant temperature for one hour, filtering, washing twice with toluene, then adding 48 ml of titanium tetrachloride, 72 ml of toluene, and then adding 2-isopropyl- 2-isoamyl-1,3-dimethoxypropane 2mL, kept at 110°C for 0.5 hours, filtered, then added 48ml of titanium tetrachloride, 72ml of toluene, treated once at 110°C for 0.5 hours, then filtered , the obtained s...

experiment Embodiment 1

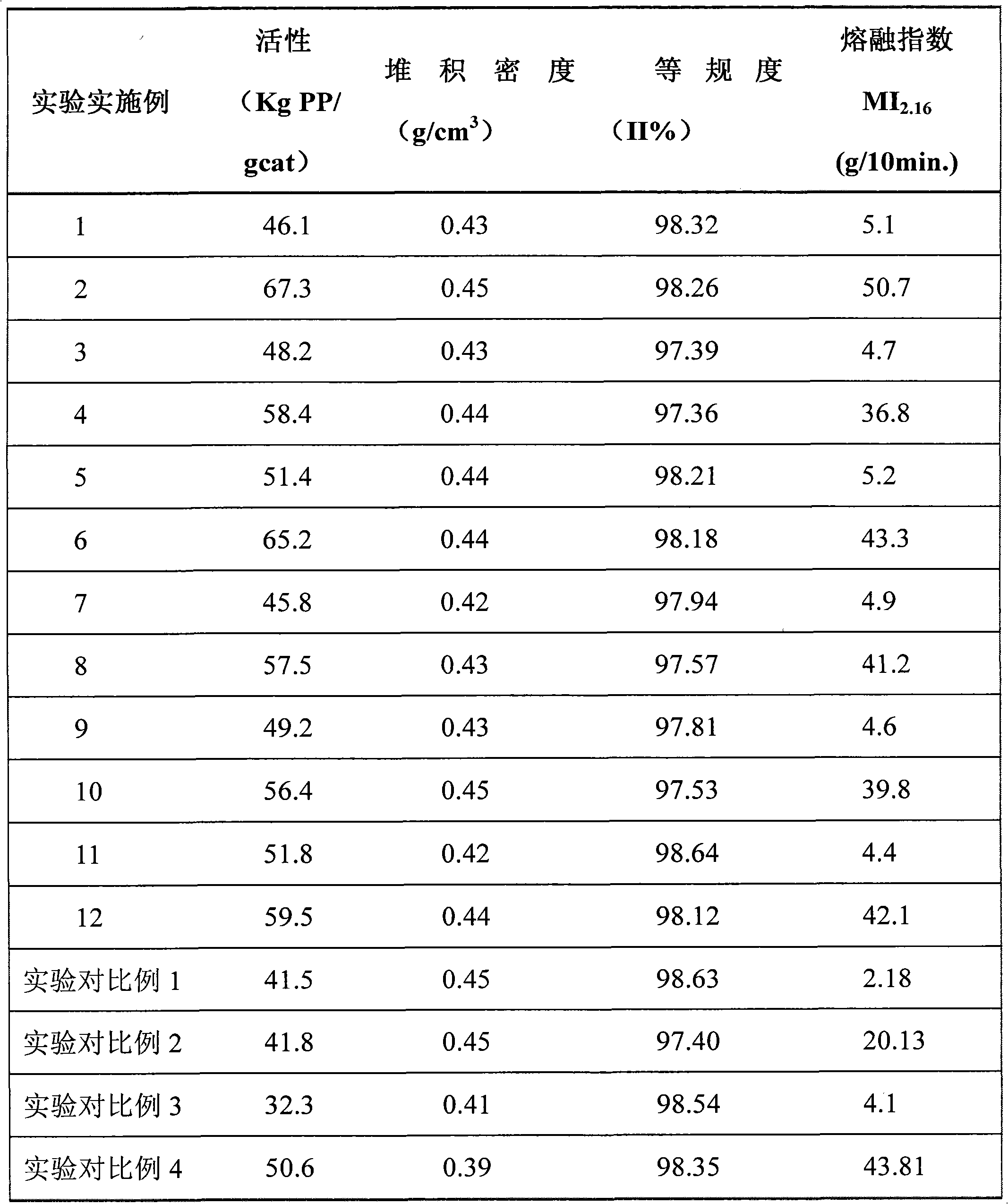

[0049] After 5 liters of stainless steel autoclaves were fully replaced with nitrogen, 5 milliliters of concentrations were added to be a hexane solution of 0.5 mol / liter of triethylaluminum and 1 milliliter of concentrations to be 1 mol / liter of methylcyclohexyldimethoxysilane ( CMMS) hexane solution and 10 mg of catalyst prepared in Example 1, then add 10 milliliters of hexane to flush the feed line, then add 1 liter (under standard state) hydrogen, and 2 liters of refined propylene, and heat up to 70 ° C. Polymerization was carried out at temperature for 1 hour. After the reaction, the temperature of the reactor was lowered and the stirring was stopped to discharge the reaction product to obtain an olefin polymer. See Table 1 for details of the results.

experiment Embodiment 2

[0051] After 5 liters of stainless steel autoclaves were fully replaced with nitrogen, 5 milliliters of concentrations were added to be a hexane solution of 0.5 mol / liter of triethylaluminum and 1 milliliter of concentrations to be 1 mol / liter of methylcyclohexyldimethoxysilane ( CMMS) hexane solution and 10 mg of catalyst prepared in Example 1, then add 10 milliliters of hexane to rinse the feed line, then add 4 liters (under standard state) of hydrogen, and 2 liters of refined propylene, and heat up to 70 ° C. Polymerization was carried out at temperature for 1 hour. After the reaction, the temperature of the reactor was lowered and the stirring was stopped to discharge the reaction product to obtain an olefin polymer. See Table 1 for details of the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com