Water emulsion containing avermectin and carbosulfan and its preparation method

A technology of abamectin and water-emulsion, which is applied in the field of water-emulsion containing abamectin and carbosulfan and its preparation, can solve the problems of long residual effect period and achieve the effect of improving the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

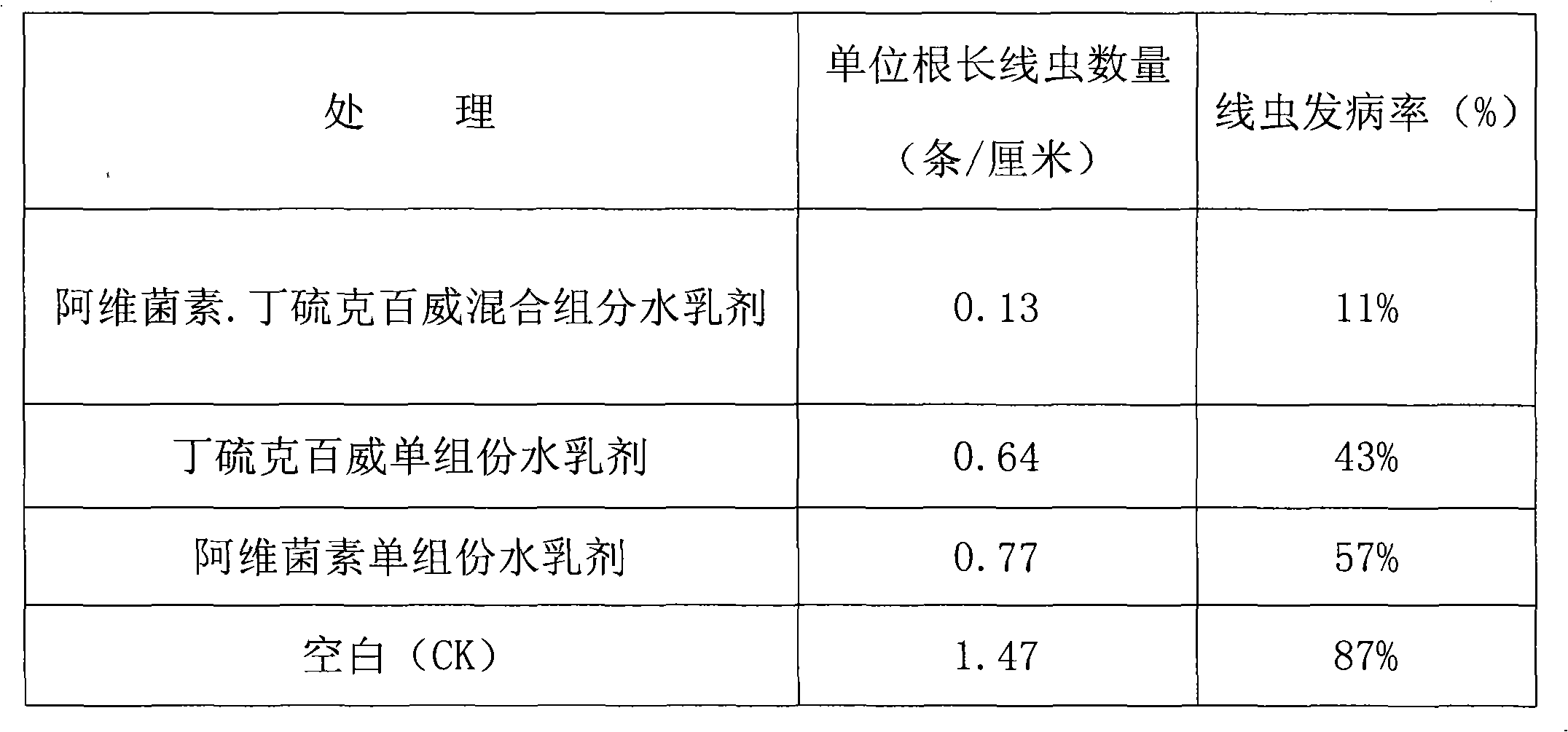

Examples

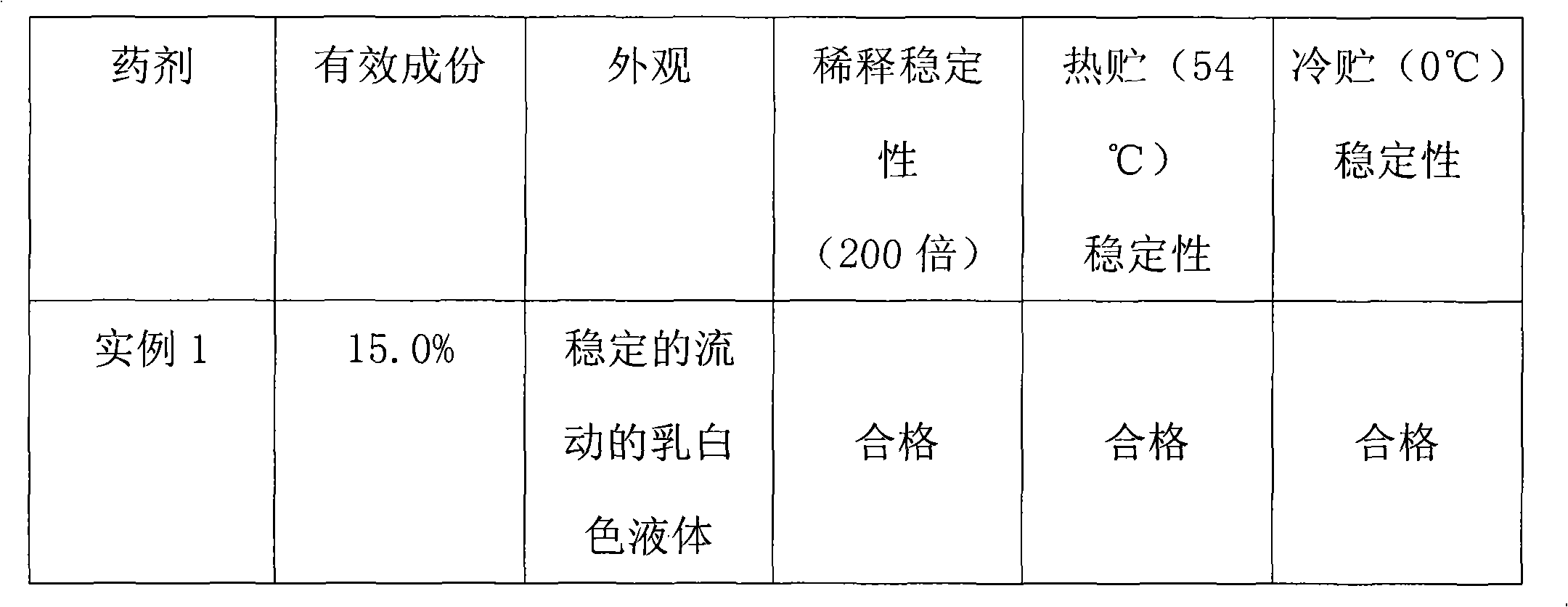

Embodiment 1

[0030] Abamectin. Carbosulfan 15.0%: Alkylphenol polyoxyethylene ether 5.0%, xylene 5.0%, ethylene glycol 4.0%, epoxy soybean oil 2.0%, xanthan gum 0.2%, deionized water to 100%.

[0031] When processing water emulsion, it is carried out in an emulsification dispersion tank. Firstly, the weighed avermectin, carbosulfan and organic solvent are mixed evenly under mechanical stirring to form an oil phase; water and stabilizer, antifreeze Put the additives and additives into the emulsification and dispersion kettle, and start stirring at a speed of 6000 rpm, then put the oil phase into the emulsification and dispersion kettle, and stir for 30-60 minutes to make it a uniform emulsion.

example 2

[0033] Abamectin. Carbosulfan 20.0%: Alkylphenol polyoxyethylene ether 2.0%, phenethylphenol polyoxyethylene ether 3.0%, methanol 8.0%, glycerol 5.0%, epoxy soybean oil 2.0% , xanthan gum 0.2%, sodium hydroxymethylcellulose 1.0%, deionized water to 100%.

[0034] First, put the weighed avermectin, carbosulfan, methanol, alkylphenol polyoxyethylene ether, and phenethylphenol polyoxyethylene ether into the emulsification dispersion kettle and mix evenly. Stirring is started at low temperature to form an oil phase; after mixing deionized water, glycerin, epoxidized soybean oil, xanthan gum, and sodium hydroxymethyl cellulose, they are slowly put into an emulsification dispersion kettle, and stirred for about 40 minutes to make it Become a homogeneous emulsion.

example 3

[0036] Abamectin. Carbosulfan 25.0%: castor oil polyoxyethylene ether 12.0%, solvent naphtha 10.0%, propylene glycol 5.0%, epichlorohydrin 2.0%, polyvinyl alcohol 1.0%, deionized water to 100% .

[0037] First, put the weighed avermectin-carbofuran, solvent oil, and castor oil polyoxyethylene ether into the emulsification dispersion kettle and mix evenly, and start stirring at a speed of 8000 rpm to form an oil phase; After mixing deionized water, propylene glycol, epichlorohydrin and polyvinyl alcohol, slowly put it into the emulsification dispersion tank and stir for about 50 minutes to make it into a uniform emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com