Pretreatment method for industrial wastewater of pyrethroid

A technology for producing pyrethroids and wastewater, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of poor pretreatment effect and poor biodegradability of pyrethroid wastewater To achieve stable and effective water treatment effects, ensure water treatment effects, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 The application of water treatment in a pesticide factory by the pretreatment method of pyrethroid production wastewater.

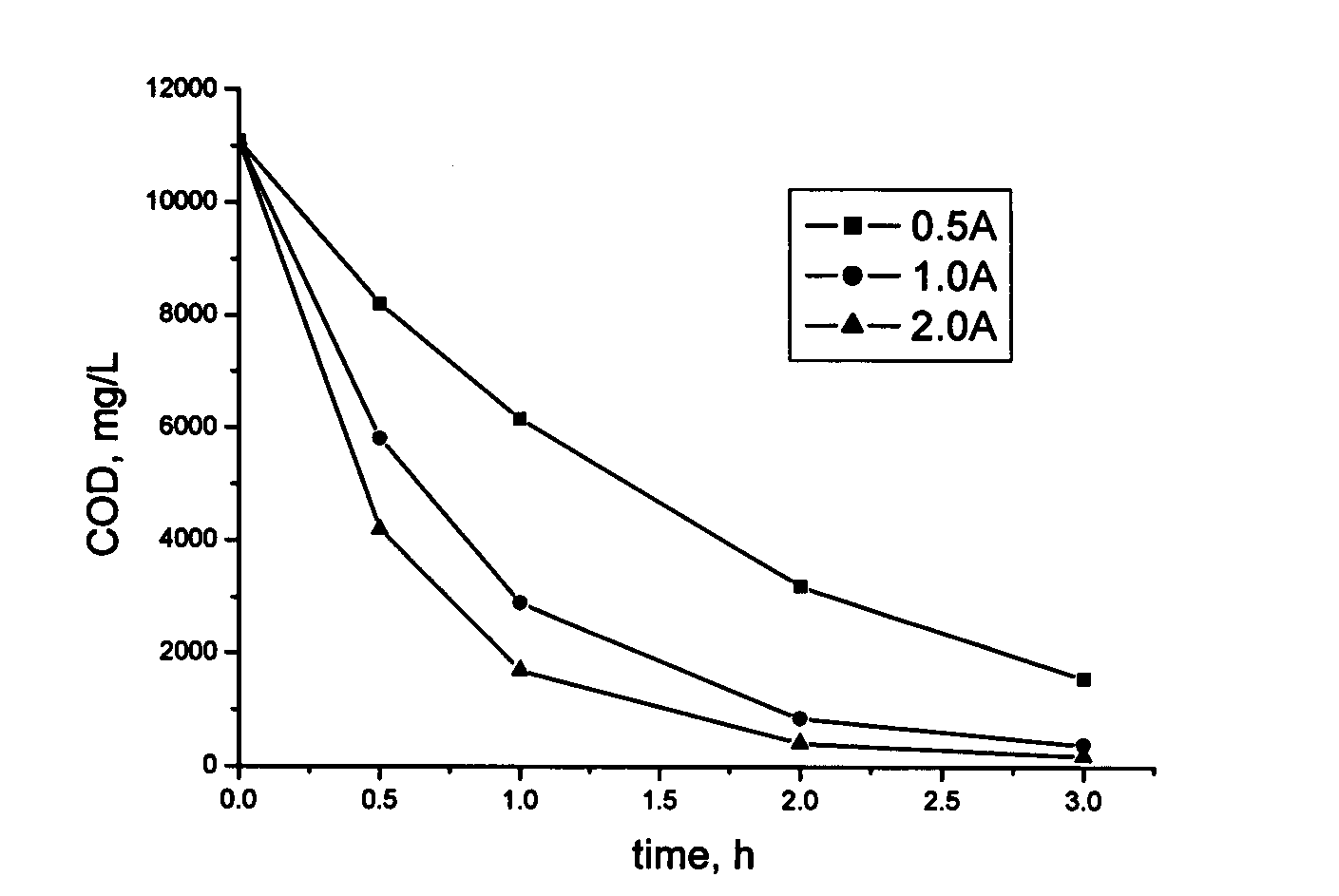

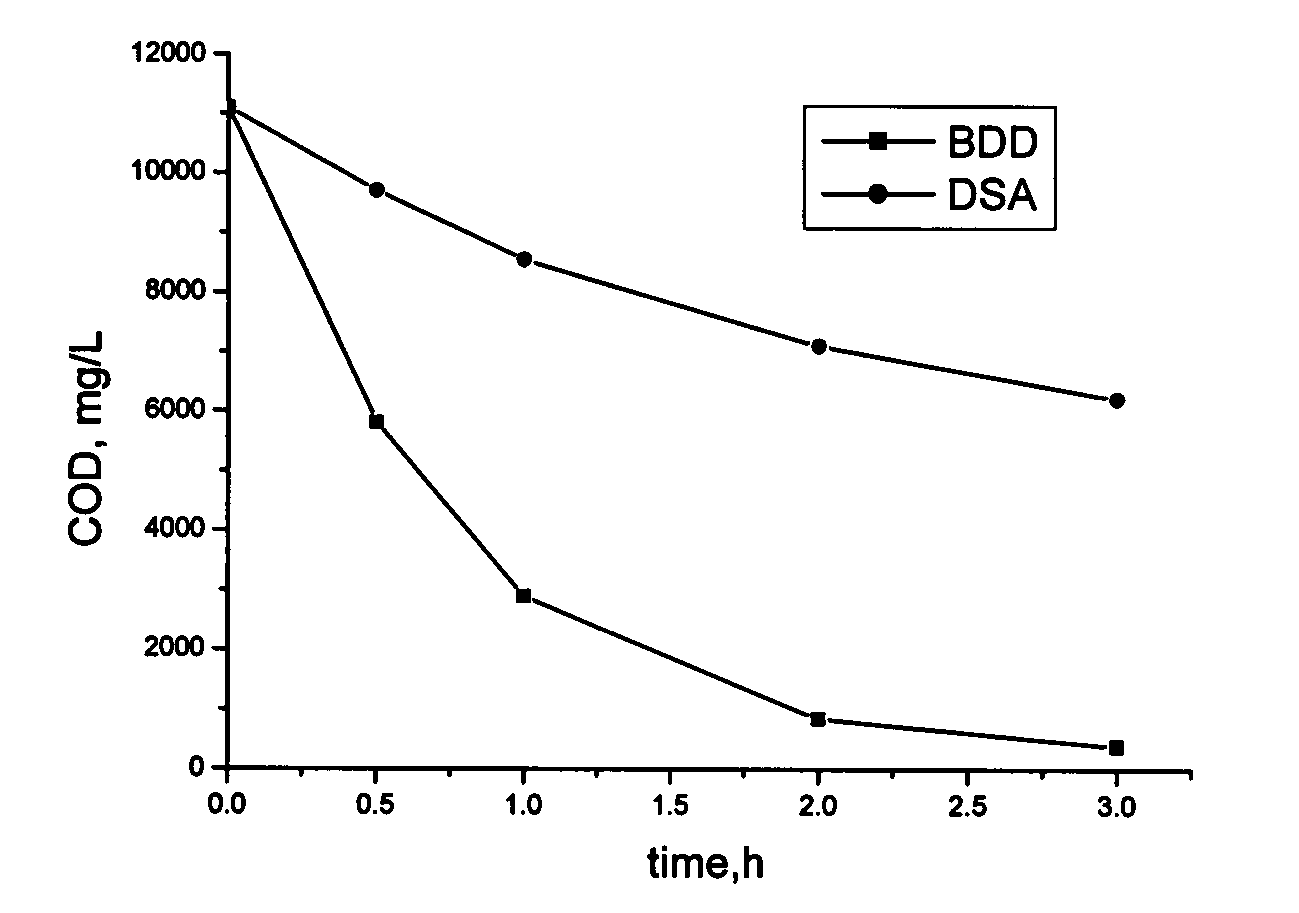

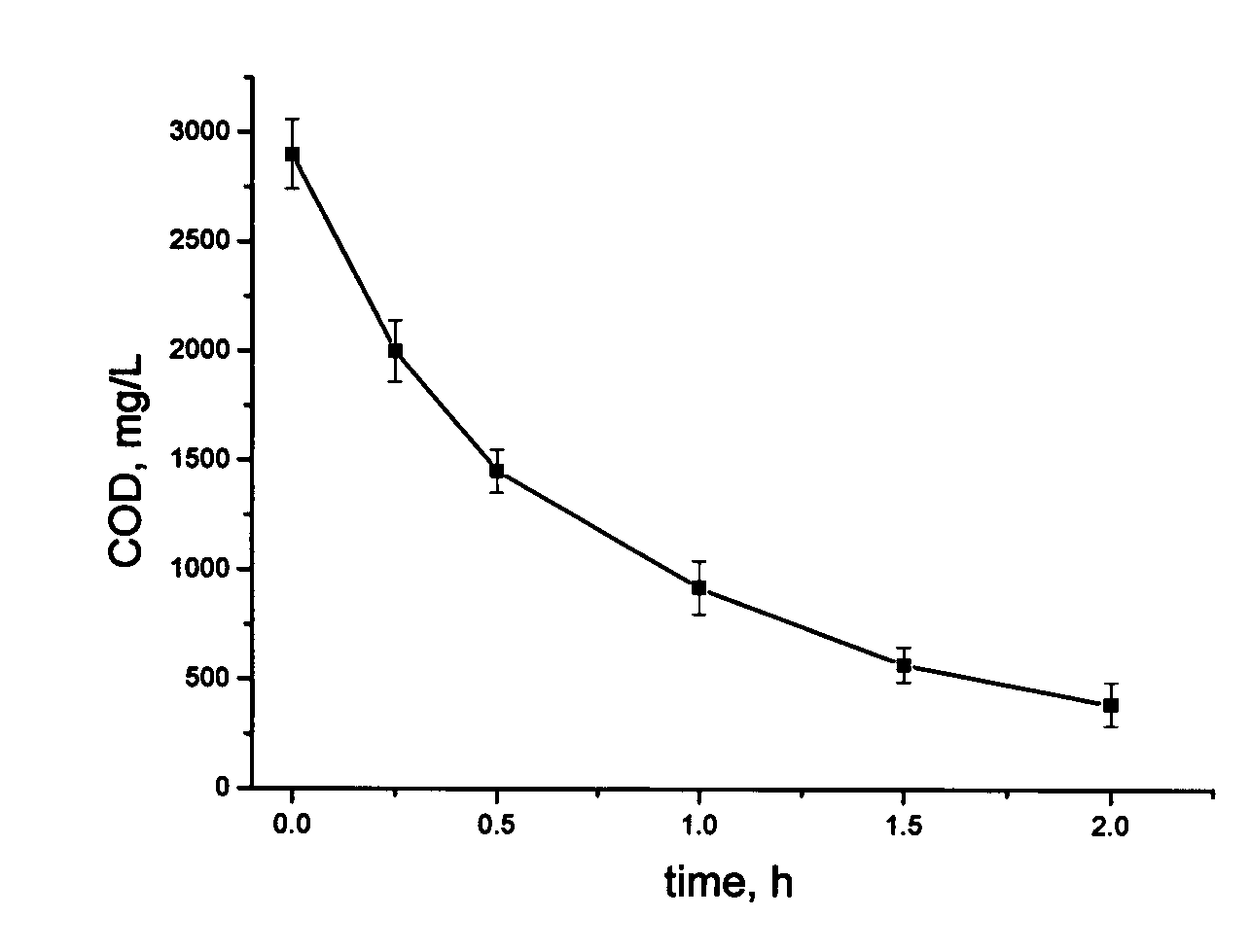

[0034] The pyrethroid production wastewater discharged from the production line of a pesticide factory, the mixed wastewater is dark yellow as a whole and has a certain pungent smell. After analysis, the pollutants in the wastewater mainly include chloramphenicol, triethylamine, toluene, and Alkanes, methanol, benzene, thionyl chloride, chloroform, tetrahydrofuran, carbon tetrachloride, tert-butanol, CN - , SO 4 2- , Cl - etc., it has the following characteristics: the overall waste water is dark yellow, has a strong pungent odor and a certain amount of suspended solids, and the concentration of pollutants is high (COD Cr Between 18000-20000mg / L), it is difficult to biodegrade and naturally degrade, and the wastewater contains a certain amount of oil. It can be seen that the composition of the wastewater is very complex, containing ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com