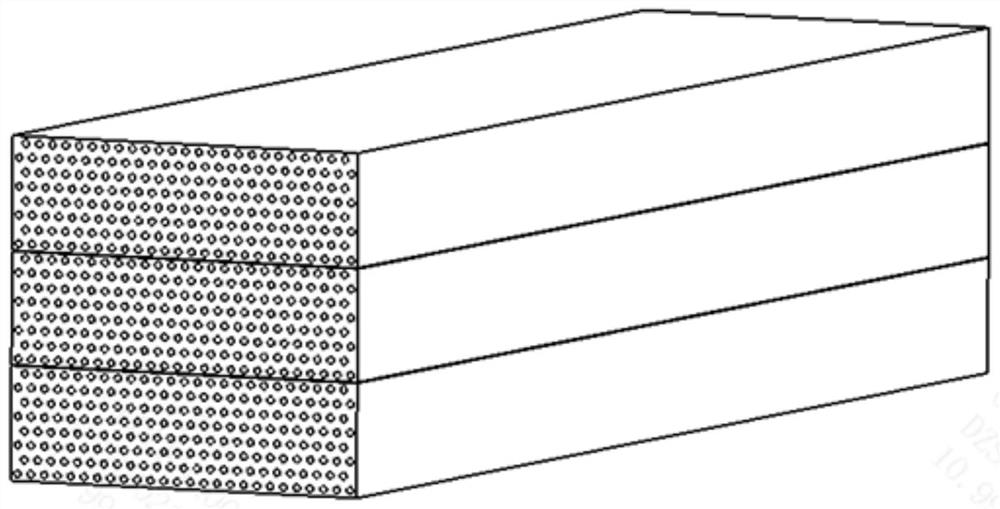

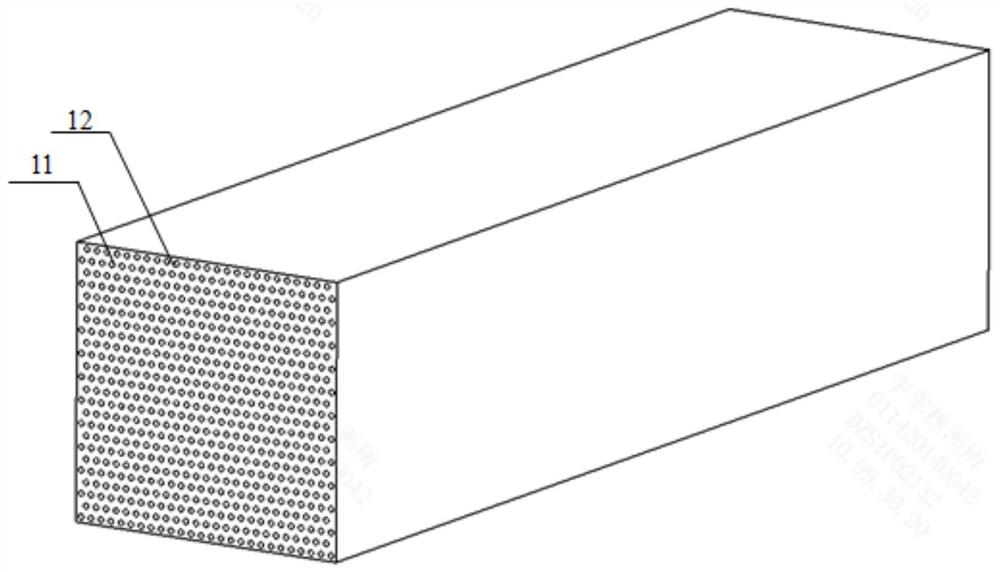

Integral polyurethane foaming synthetic sleeper and preparation method thereof

A polyurethane, integrated technology, applied in the field of polyurethane composite materials, can solve the problems of high cost, poor product performance, exposed rebar, etc., and achieve the effect of fewer processes and excellent product mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

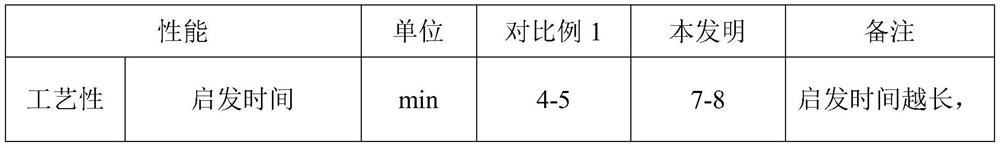

Embodiment 1

[0046] A method for preparing integral polyurethane foam synthetic sleepers, comprising the following raw materials:

[0047]1) The continuous fiber (glass fiber) is 19200Tex, and the mass ratio of continuous fiber is 50%.

[0048] 2) Polyurethane resin, the proportion is as follows: Polyether polyol component 1 (glycerol-propylene oxide polyether, average functionality 3, hydroxyl value 410mKOH / g, viscosity 320mp.s (25°C)): 100 parts , polyether polyol component 2 (sorbitol-propylene oxide polyether, average functionality 6, hydroxyl value 550mKOH / g, viscosity 1200mp.s (25°C)): 100 parts, catalyst 1 (triethylene Diamine): 6 parts, catalyst 2 (dibutyltin dilaurate): 2 parts, foaming agent water: 2 parts, foam stabilizer (organosiloxane-polyether copolymer): 2 parts, flame retardant (tris(2-chloroethyl)phosphate): 1 part, isocyanate (diphenylmethane diisocyanate, NCO content 30.4%, average functionality 2.5): 260 parts.

[0049] When foaming polyurethane resin, mix polyether ...

Embodiment 2

[0057] The specific production process of this implementation case is as follows:

[0058] a. Preheating the steel belt laminator in advance: The steel belt laminator adopts three-stage preheating, and the temperatures of the front, middle and back three stages are 45°C, 65°C, and 45°C respectively.

[0059] b. Yarn arrangement: According to the product density and product size, the continuous fiber threading arrangement is carried out. The continuous fiber used is glass fiber, the yarn type is 19200TEX, and the number of yarns is 800;

[0060] c. Pulling head traction: press the steel belt laminator against the leading head, then the laminator rotates, and the yarn is driven into the cavity of the laminating machine through the leading head. The traction speed of the laminator is 0.7m / min;

[0061] d. Glue injection: start the polyurethane glue injection machine, pour polyurethane resin on the yarn through the glue injection tube. The glue injection flow rate is controlled ...

Embodiment 3

[0070] A method for preparing integral polyurethane foam synthetic sleepers, comprising the following raw materials:

[0071] 1) The continuous fiber (glass fiber) is 19200Tex, and the mass ratio of continuous fiber is 62%.

[0072] 2) The resin ratio is as follows: Polyether polyol component 1 (glycerol-propylene oxide polyether, average functionality 3, hydroxyl value 410mKOH / g, viscosity 320mp.s (25°C)): 100 parts, poly Ether polyol component 2 (sorbitol-propylene oxide polyether, average functionality 6, hydroxyl value 550mKOH / g, viscosity 1200mp.s (25°C)): 100 parts, catalyst 1 (triethylenediamine ): 6 parts, catalyst 2 (dibutyltin dilaurate): 2 parts, foaming agent water: 1 part, foam stabilizer (organosiloxane-polyether copolymer): 2 parts, flame retardant (three (2-chloroethyl)phosphate): 1 part, isocyanate (diphenylmethane diisocyanate, NCO content 30.4%, average functionality 2.5): 250 parts.

[0073] The specific production process of this implementation case is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com