Sludge hydrolysis acidification system using membrane bioreactor

A technology of sludge hydrolysis acidification and membrane bioreactor, which is applied in the field of hydrolysis acidification and separation of hydrolyzate, can solve problems such as difficult cleaning, increased power consumption, and poor operating sanitation conditions, and achieves easy automatic control and reduced sludge load, increase the effect of volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

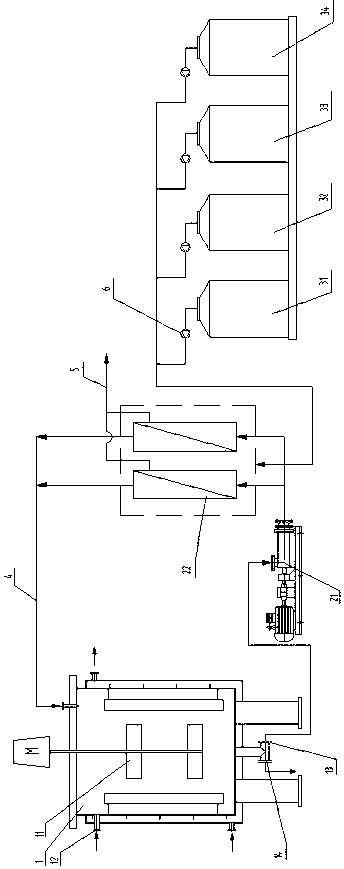

[0020] Such as figure 1 As shown, a stirring mechanism 11 powered by a motor is arranged in the sludge hydrolysis acidification tank 1, a sludge feed port 12 is provided at the upper end of the sludge hydrolysis acidification tank 1, and a sludge discharge port 13 is provided at the lower end. A sludge discharge port 14 is provided at the lower end of the hydrolysis acidification tank 1 .

[0021] The ceramic membrane separation system includes a membrane-feeding screw pump 21 and a plurality of ceramic membrane modules 22 composed of stainless steel membrane shells and inorganic ceramic membrane elements. The discharge port of the membrane-feeding screw pump 21 is connected to the feed port of each ceramic membrane module 22 .

[0022] The online cleaning system is mainly composed of an acid dosing tank 31 , an alkali dosing tank 32 , a clean water tank 33 and a strong oxidant tank 34 .

[0023] The sludge discharge port 13 of the sludge hydrolysis acidification tank 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com