Toughening-antiflaming type epoxy resin and preparation method thereof

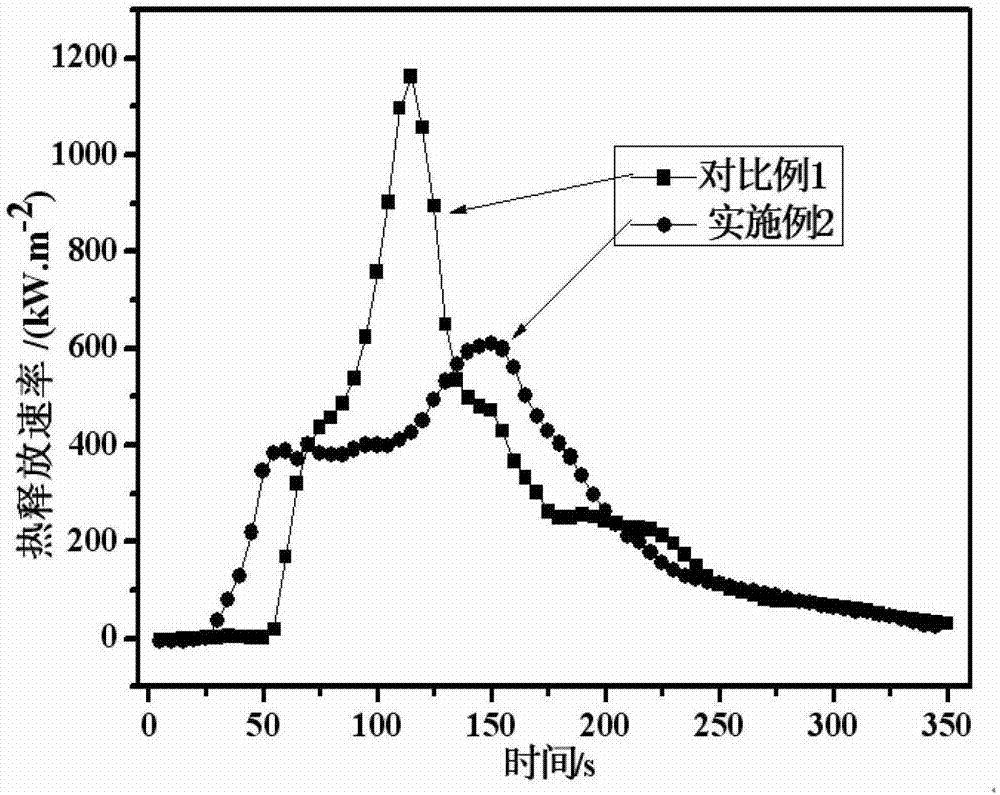

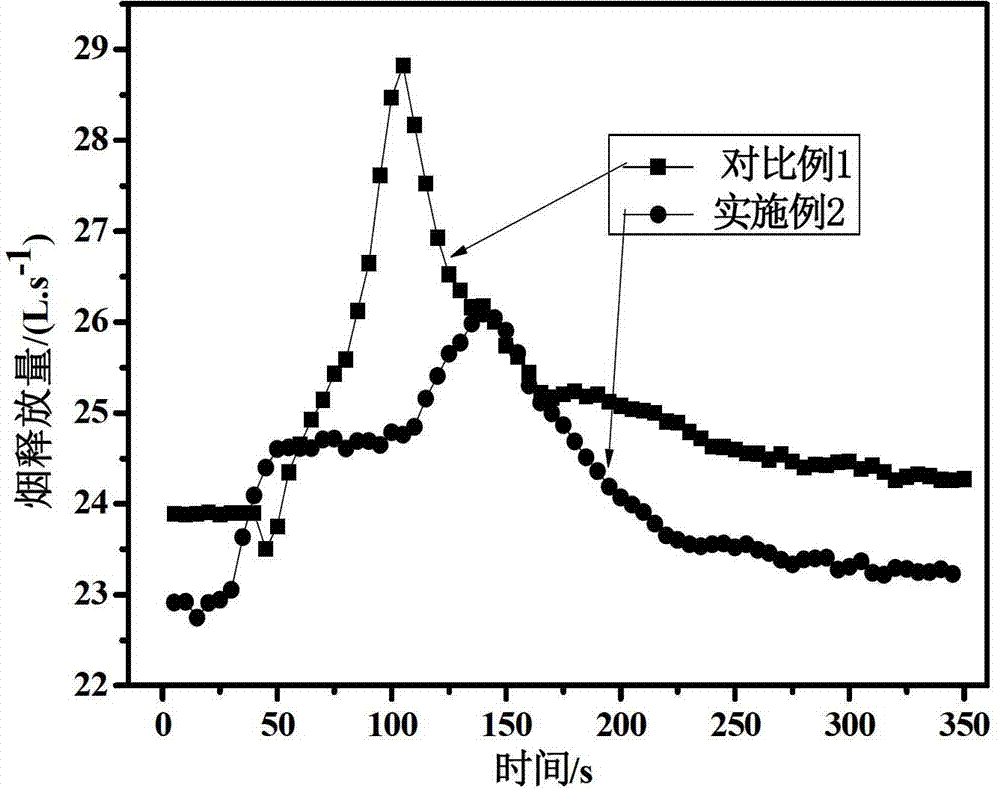

An epoxy resin and flame-retardant technology, applied in the field of new functional polymer materials and their preparation, can solve the problem that a single performance cannot effectively improve the use value of materials, and achieve non-toxic by-products, heat release rate and smoke density decrease , environmental and human safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

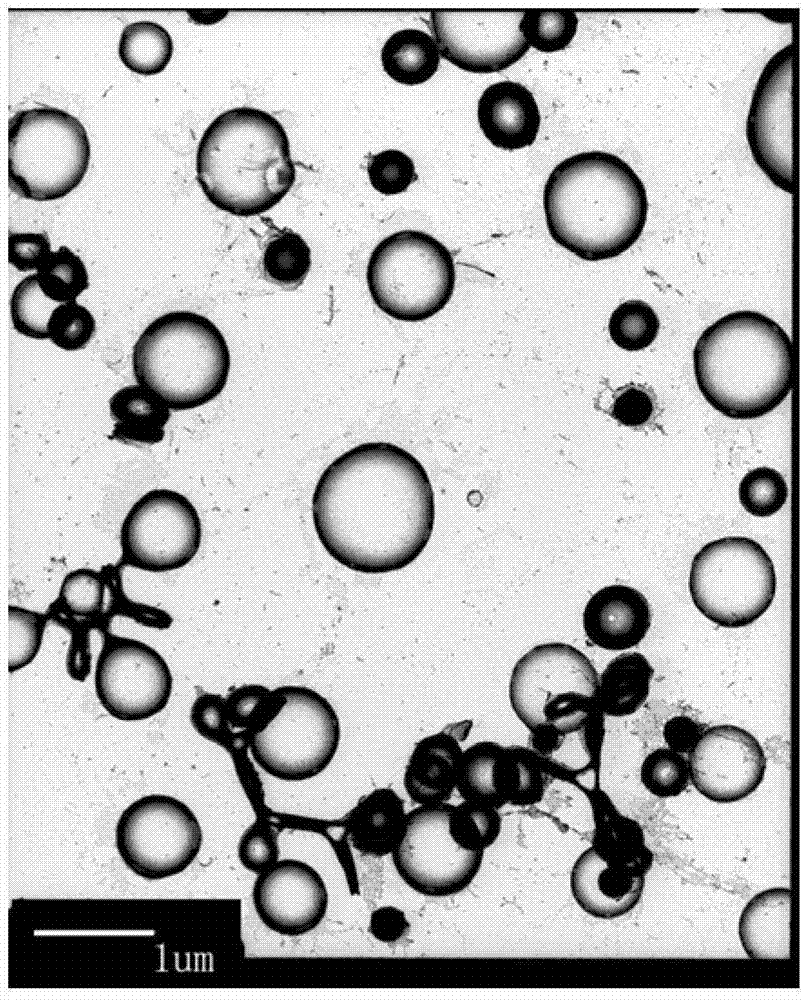

[0036] Stir and mix 100 parts of epoxy resin monomer 618 (E-51) and 5 parts of core-shell microspheres at 30°C, wherein the particle size distribution of core-shell microspheres is 0.1-0.5 μm, and the thickness of the shell and core layers The ratio is 1:10, the shell layer is composed of methyl methacrylate and divinylbenzene cross-linked polymer, and the ammonium polyphosphate in the core layer: melamine: melamine resin = 10:5:5. Add 15 parts of m-phenylenediamine to the mixture of epoxy monomer and core-shell microspheres, stir and mix evenly at 30°C, pour into a preheated specific mold, and vacuum for 30 minutes to remove air bubbles in the mixture. After defoaming, it was cured at 60°C for 2 hours and at 150°C for 2 hours. After cooling, it was released from the mold to obtain a toughened-flame-retardant epoxy resin material.

Embodiment 2

[0038] Stir and mix 100 parts of epoxy resin monomer 6101 (E-44) and 10 parts of core-shell microspheres at 30°C. The particle size distribution of the core-shell microspheres is about 0.5-1 μm, and the shell layer is made of styrene It is composed of divinylbenzene cross-linked polymer, ammonium polyphosphate in the core layer: melamine: melamine resin = 10:0:0. Add 14 parts of polyethylene polyamine to the mixture of epoxy monomer and core-shell microspheres, stir and mix evenly at 30°C, pour into a preheated specific mold, and vacuum for 30 minutes to remove air bubbles in the mixture. After defoaming, it was cured at 60°C for 2 hours, 120°C for 1 hour, and 150°C for 1 hour. After cooling, it was demolded to obtain a toughened-flame-retardant epoxy resin material.

Embodiment 3

[0040] Stir and mix 100 parts of epoxy resin monomer 618 (E-51) and 25 parts of core-shell microspheres at 60°C. Among them, the particle size distribution of core-shell microspheres is 2-2.5 μm, and the thickness of the shell and core layers The ratio is 2:10, the shell layer is composed of acrylonitrile and divinylbenzene cross-linked polymer, and the ammonium polyphosphate in the core layer: melamine: melamine resin = 10:1:5. Add 22 parts of diethylmethyldiamine to the mixture of epoxy monomer and core-shell microspheres, stir and mix evenly at 60°C, pour it into a preheated special mold, and vacuum for 30 minutes to remove the mixture medium air bubbles. After defoaming, it was cured at 120°C for 4 hours and at 180°C for 4 hours, and then demoulded after cooling to obtain a toughened-flame-retardant epoxy resin material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com