Emulsion of water-based primer for EVA materials

A treatment agent, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of harming the health of production personnel, unsatisfactory EVA bonding effect, waste of resources, etc., and is beneficial to environmental protection and the use of production personnel. Healthy, easy-to-control, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

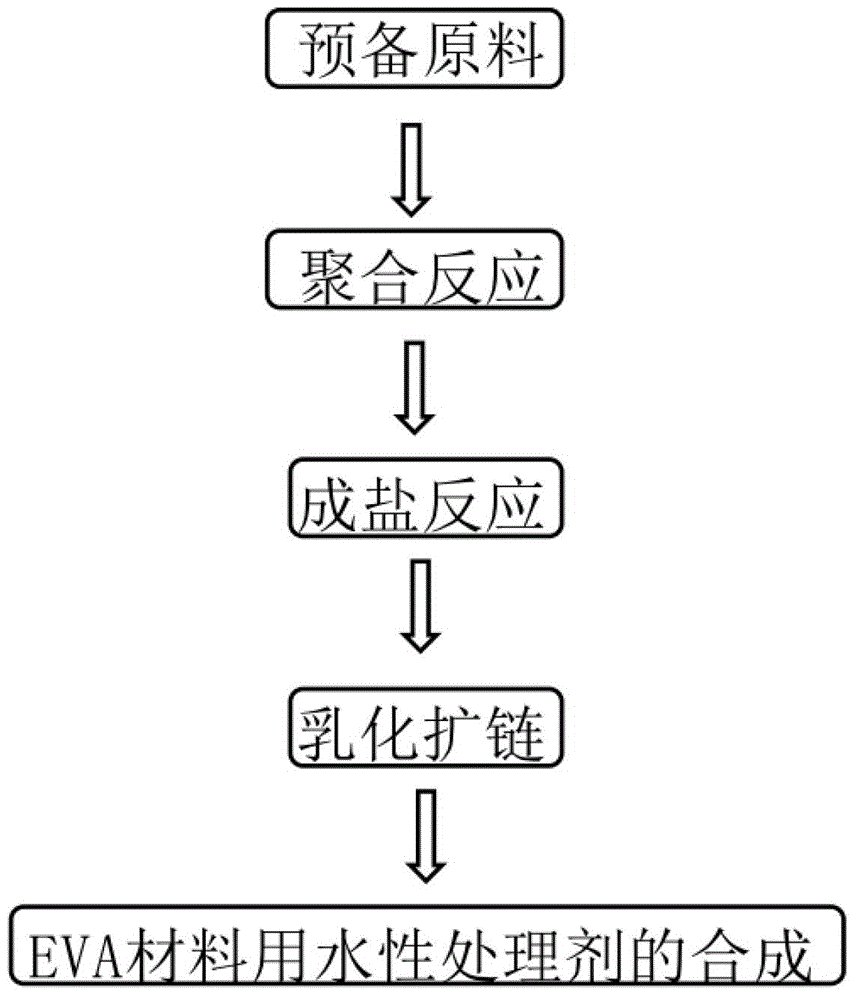

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of EVA material aqueous treatment agent emulsion that the embodiment of the present invention provides, it is made by the raw material of following weight part:

[0044] 690 parts of hydroxyl-terminated polybutadiene (Mn=2000),

[0045] 32 parts of 2,2-dimethylolacetic acid,

[0046] 135 parts of 1,6-hexamethylene diisocyanate,

[0047] 0.1 part of dibutyltin dilaurate,

[0048] 350 parts of acetone,

[0049] 9 parts of triethylamine,

[0050] 900 parts of deionized water,

[0051] 25 parts of ethylenediamine.

[0052]The preparation method of described EVA material aqueous treatment agent emulsion, comprises the following steps:

[0053] (1) Prepare raw materials: the mass parts of raw materials and their components are as follows:

[0054] 690 parts of hydroxyl-terminated polybutadiene (Mn=2000),

[0055] 32 parts of 2,2-dimethylolacetic acid,

[0056] 135 parts of 1,6-hexamethylene diisocyanate,

[0057] 0.1 part of dibutyltin dilaurate...

Embodiment 2

[0071] Embodiment 2: EVA material aqueous treatment agent emulsion provided by the present invention and preparation method are basically the same as embodiment 1, and its difference is:

[0072] The mass parts of raw material and each component thereof are as follows:

[0073] 650 parts of hydroxyl-terminated chlorinated polyethylene (Mn=1000),

[0074] 35 parts of 2,2-dimethylolacetic acid,

[0075] 150 parts of 1,6-hexamethylene diisocyanate,

[0076] Stannous octoate 0.07 parts,

[0077] Benzene 380 parts,

[0078] 7 parts of triethylamine,

[0079] 1000 parts of deionized water,

[0080] 20 parts of ethylenediamine.

Embodiment 3

[0081] Embodiment 3: a kind of EVA material water-based treatment agent emulsion provided by the present invention and preparation method are basically identical with embodiment 1 and 2, and its difference is:

[0082] The mass parts of raw material and each component thereof are as follows:

[0083] 700 parts of hydroxyl-terminated polyisoprene (Mn=1500),

[0084] 2,2-dimethylol propionic acid 30 parts,

[0085] 180 parts of isophorone diisocyanate,

[0086] 0.08 parts of dibutyltin dilaurate,

[0087] 400 parts of methyl ethyl ketone,

[0088] 10 parts of triethylamine,

[0089] 800 parts of deionized water,

[0090] Hexamethylenediamine 27 parts.

[0091] Although the solvent used in the present invention is inert to isocyanate, it is soluble in water and has good dissolving ability, so that the product can obtain excellent performance.

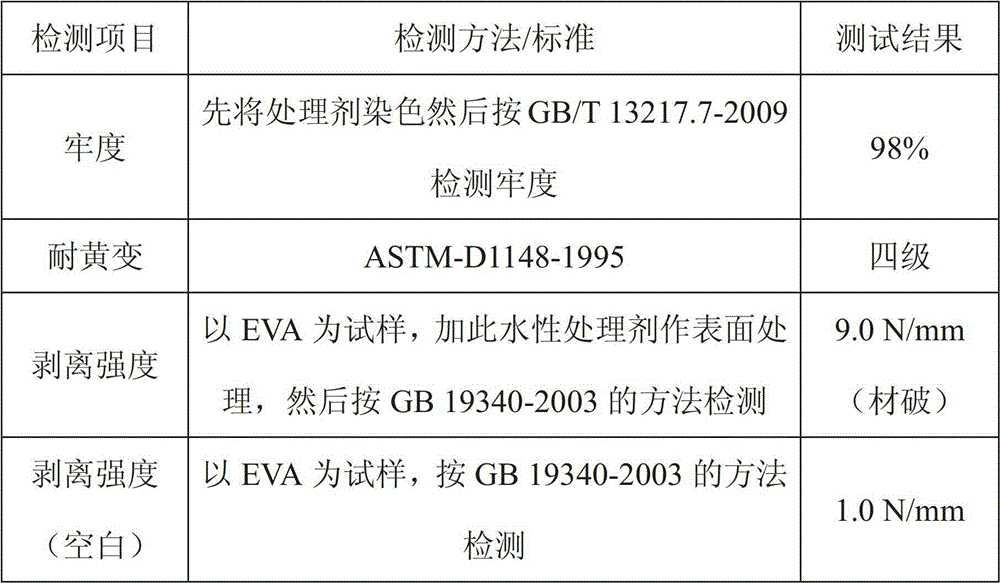

[0092] The EVA water-based treatment agent provided by the invention has no discharge of volatile organic compounds during use, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com