Novel physical hydrogel and usage thereof

A physical water and gel technology, which is applied to the delivery of non-active ingredients in medical preparations, prostheses, aerosols, etc., can solve the problems of complex production process, poor controllability of gel properties, and difficult purification. To achieve the effect of simple preparation process, good biocompatibility and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The carboxylic acid of cholesteryl succinate was chlorinated with thionyl chloride, and then reacted with dihydroxypolyethylene glycol 2000 in dioxane at 50°C for 24 h, which was enough to neutralize the acid produced by the reaction. A certain amount of pyridine is used as a catalyst and an acid-binding agent. After the reaction is complete, the reactant obtained is precipitated in ether, centrifuged, and vacuum-dried to obtain cholesterol-polyethylene glycol-cholesterol.

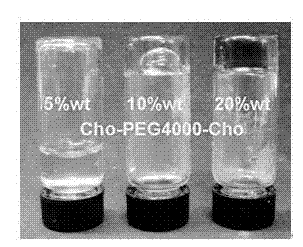

[0031] According to the mass percentage of cholesterol-polyethylene glycol-cholesterol as 20%wt, the hydrogel can be obtained after swelling in distilled water at 4°C for about 8 h.

[0032]

Embodiment 2

[0034] The carboxylic acid of cholesteryl succinate was chlorinated with thionyl chloride, and then reacted with diaminopolyethylene glycol polyethylene glycol 4000 in dioxane at 50 °C for 24 h, enough to neutralize the reaction Triethylamine in the amount of acid produced is used as a catalyst and an acid-binding agent. After the reaction is complete, the reactant obtained is precipitated in ether, centrifuged, and vacuum-dried to obtain cholesterol-polyethylene glycol-cholesterol.

[0035] According to the mass percentage of cholesterol-polyethylene glycol-cholesterol as 5% wt, it was swelled in distilled water at 4°C for about 8 h, and a sol with a certain viscosity was obtained.

[0036]

Embodiment 3

[0038] After chlorinating the carboxylic acid of cholesteryl succinate with thionyl chloride, react with dihydroxypolyethylene glycol 4000 in dioxane at 50 °C for 24 h, add enough acid to neutralize the reaction A certain amount of sodium carbonate or potassium carbonate is used as a catalyst and an acid-binding agent. After the reaction is complete, the reactant obtained is precipitated in ether, centrifuged, and vacuum-dried to obtain cholesterol-polyethylene glycol-cholesterol.

[0039] According to the mass percentage of cholesterol-polyethylene glycol-cholesterol as 10% wt, it was swelled in distilled water at 4°C for about 8 h, and a sol solution with high viscosity was obtained.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com