Method for preparing ACE (Angiotensin Converting Enzyme) inhibitory peptide by hydrolyzing rice protein isolate with complex enzyme

A technology for compound enzyme hydrolysis and protein separation, applied in the field of functional food processing, can solve the problems of low peptide yield and ACE inhibitory activity, high ash content, and achieve the effect of strong activity, low ash content, and shortened hydrolysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

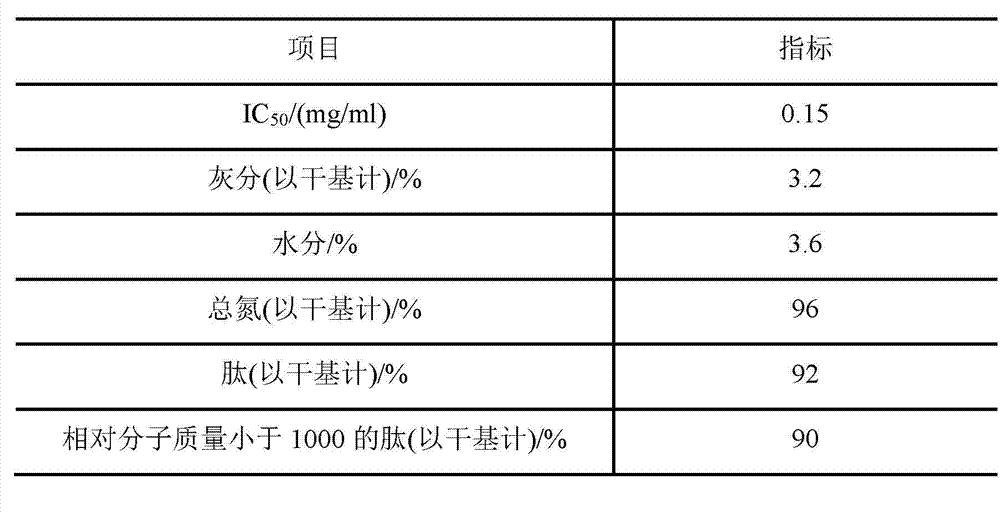

Embodiment 1

[0021] Alkaline protease (Alcalase 2.4L FG, 2.4AU / g, produced by Bacillus subtilis, whose activity was determined by kinetic diformaldehyde casein method.) and trypsin (Trypsin Novo 6.0, 1250USP / mg, produced by Danish Novozymes Company) were adopted. Extracted from porcine pancreas, and its activity was determined by ultraviolet spectrophotometry.) The preparation process conditions are: the mass volume ratio concentration of the rice protein isolate aqueous solution is 7.5%, the pH value is 9, the reaction temperature is 50°C, and the enzyme amount is 54AU / kg , after 120 min of hydrolysis reaction, quickly adjust the reaction temperature to 37°C, pH value to 8, and add trypsin hydrolysis reaction for 30 min according to the amount of enzyme added at 20 USP / kg. Then adjust the pH to 5.0 to inactivate enzymes and remove macromolecular peptides. The enzymatic solution was centrifuged at 4000 r / min for 20 min, and the supernatant was separated through an ultrafiltration membrane ...

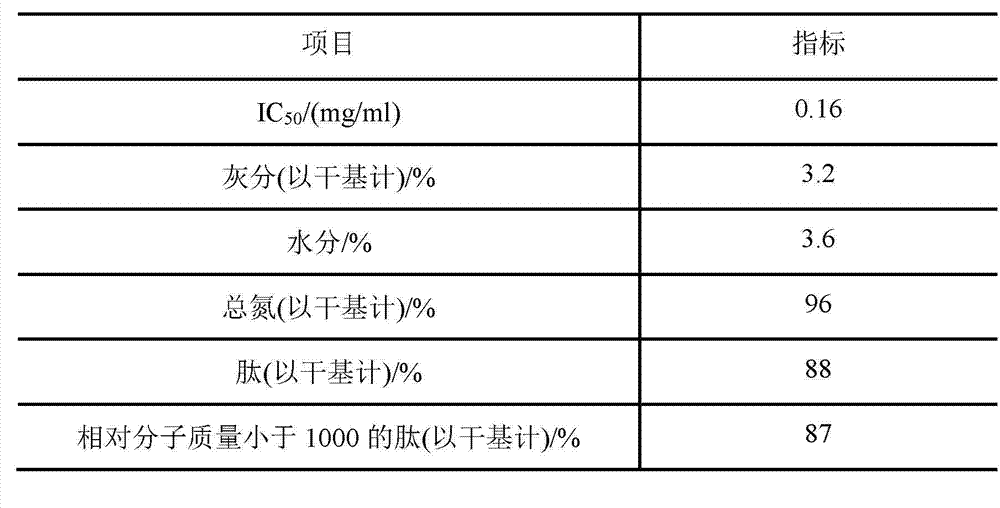

Embodiment 2

[0025] Alkaline protease (Alcalase 2.4L FG, 2.4AU / g, produced by Bacillus subtilis, whose activity was determined by kinetic diformaldehyde casein method) and trypsin (Trypsin Novo 6.0, 1250 USP / mg, It is extracted from porcine pancreas, and its activity is determined by ultraviolet spectrophotometry.) The preparation process conditions are: the mass volume ratio concentration of rice protein isolate aqueous solution is 7.5%, the pH value is 9, the reaction temperature is 50°C, and the enzyme amount is 60 AU / kg, after 120 min of hydrolysis reaction, quickly adjust the reaction temperature to 37°C, pH value to 7.5, and add trypsin hydrolysis reaction for 30 min according to the amount of enzyme added at 25 USP / kg. After the reaction, adjust the pH value to 5.0, inactivate the enzyme and remove the macromolecular polypeptide. The enzymatic solution was centrifuged at 4000 r / min for 20 min, and the supernatant was separated through an ultrafiltration membrane with a molecular we...

Embodiment 3

[0029] Alkaline protease (Alcalase 2.4L FG, 2.4AU / g, produced by Bacillus subtilis, whose activity was determined by kinetic diformaldehyde casein method.) and trypsin (Trypsin Novo 6.0, 1250USP / mg, produced by Danish Novozymes Company) were adopted. Extracted from porcine pancreas, and its activity was determined by ultraviolet spectrophotometry.) The preparation process conditions are: the mass volume ratio concentration of rice protein isolate aqueous solution is 7.5%, the pH value is 9, the reaction temperature is 50°C, and the enzyme amount is 48 AU / kg, after 120 min of hydrolysis reaction, quickly adjust the reaction temperature to 37°C, pH value to 7.5, and add trypsin hydrolysis reaction for 30 min according to the amount of enzyme added at 12.5USP / kg. Then adjust the pH to 5.0 to inactivate enzymes and remove macromolecular peptides. The enzymatic solution was centrifuged at 4000 r / min for 20 min, the supernatant was separated through an ultrafiltration membrane with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com