Mercury contaminated soil in-situ restoration method

An in-situ remediation and mercury-contaminated technology, applied in the field of in-situ remediation of mercury-contaminated soil, can solve problems such as difficult implementation, unreasonable application of mercury-containing fertilizers and pesticides, and large land area, so as to reduce purification costs, cheap raw materials, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

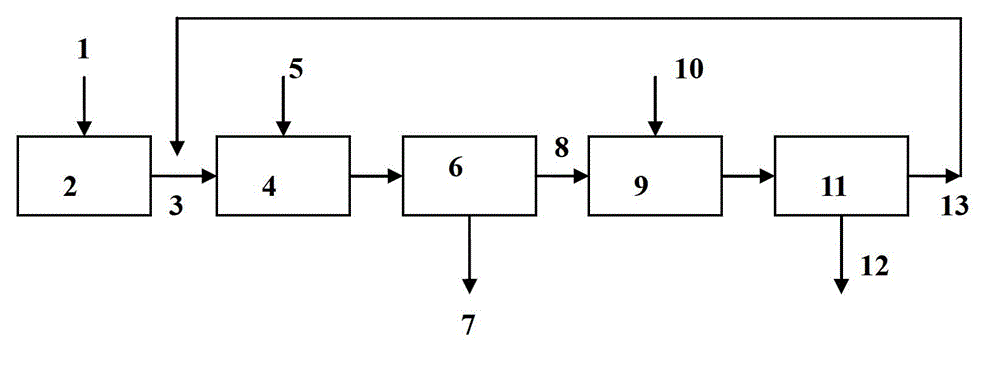

[0028] 1) Extracting agent raw material 1 (10 kg sodium iodide, 10 kg sodium sulfate, 10 kg ammonium nitrate and 10 kg ammonium thiosulfate, sodium iodide: sodium sulfate: ammonium nitrate: ammonium thiosulfate mass ratio 1:1 :1:1,) into the stirring tank 2, dissolved in 360 kg of water, and configured as an extractant 3 with a mass concentration of 10%.

[0029] 2) In the extraction kettle 4, 80 kg of mercury-contaminated soil 5 and 400 kg of extractant 3 are fully stirred and mixed, the mass ratio of mercury-contaminated soil:extractant 3 is 1:5, the stirring time is 2 hours, and the centrifuge 6 is used for centrifugation . Clean soil 7 is obtained after separation.

[0030] 3) Transfer the 330 cubic meters of extract 8 produced after centrifugation into the precipitation reactor 9, add 1 kg of sodium sulfide precipitant 10, that is, add 0.33 kg of sulfide per cubic meter of supernatant, stir well, and react for 20 minute. The centrifuge 11 is used for centrifugal separa...

Embodiment 2

[0032] 1) Extracting agent raw material 1 (10 kg ammonium iodide, 10 kg potassium sulfate, 10 kg sodium nitrate and 10 kg sodium thiosulfate, ammonium iodide: potassium sulfate: sodium nitrate: sodium thiosulfate mass ratio 1:1 :1:1,) into the stirring tank 2, dissolved in 460 kg of water, and configured as an extraction agent 3 with a mass concentration of 8%.

[0033] 2) In the extraction kettle 4, 125 kg of mercury-contaminated soil 5 and 500 kg of extractant 3 are fully stirred and mixed, the mass ratio of mercury-contaminated soil:extractant 3 is 1:4, the stirring time is 2 hours, and the centrifuge 6 is used for centrifugation . Clean soil 7 is obtained after separation.

[0034] 3) Transfer the 420 cubic meters of extract 8 produced after centrifugation into the precipitation reactor 9, add 0.84 kg of potassium sulfide precipitant 10, that is, add 0.2 kg of sulfide per cubic meter of supernatant, stir well, and react for 20 minute. The centrifuge 11 is used for centr...

Embodiment 3

[0036] 1) Extraction agent raw material 1 (3.75 kg potassium iodide, 3.75 kg ammonium sulfate, 3.75 kg potassium nitrate and 3.75 kg potassium thiosulfate, potassium iodide: ammonium sulfate: potassium nitrate: potassium thiosulfate mass ratio 1:1:1:1 ,) into the stirring tank 2, dissolved in 285 kg of water, and configured as an extractant 3 with a mass concentration of 5%. Contaminated soil: extractant mass ratio = 1:3, stirring time 2 hours, centrifuged by centrifuge 6. Clean soil 7 is obtained after separation.

[0037] 3) Transfer the 280 cubic meters of extract 8 produced after centrifugation into the precipitation reactor 9, add 0.84 kg of calcium sulfide precipitant 10, that is, add 0.3 kg of sulfide per cubic meter of supernatant, stir well, and react for 20 minute. The centrifuge 11 is used for centrifugal separation to recover the mercury sulfide 12 and realize the regeneration of the extraction agent at the same time. The regenerated extractant 13 is reused in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com