Device and method for preparing manganese dioxide ultrafine powder

An ultra-fine powder, manganese dioxide technology, used in manganese oxide/manganese hydroxide, hybrid capacitor electrodes, etc., can solve the problems of poor mixing effect of reactants, large particle size of manganese dioxide, poor product performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

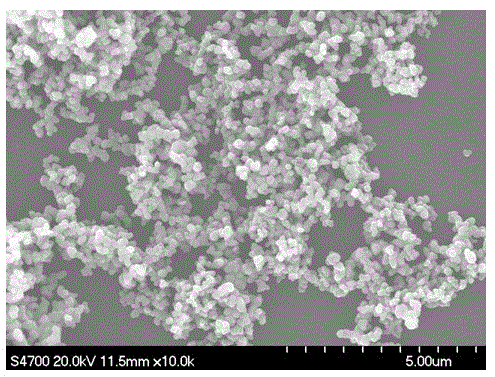

[0025] (1) Weigh 15.8 g of analytical grade KMnO 4 Uniformly dispersed in 1 L of deionized water to prepare solution A with a concentration of 0.1 mol / L; 0.1 g of triblock copolymer (P123, polyethylene oxide-polypropylene oxide-polyethylene oxide triblock segment copolymer) was uniformly dispersed in 20 mL of ethanol, and then this solution was added to a solution containing 25.35 g of analytically pure MnSO 4 solution, continuously stirred for 48 h, and the uniformly mixed solution was prepared into 0.1 g / L P123 concentration of 0.15 mol / L MnSO 4 The reaction solution B; inject the prepared solution into the storage tanks A and B.

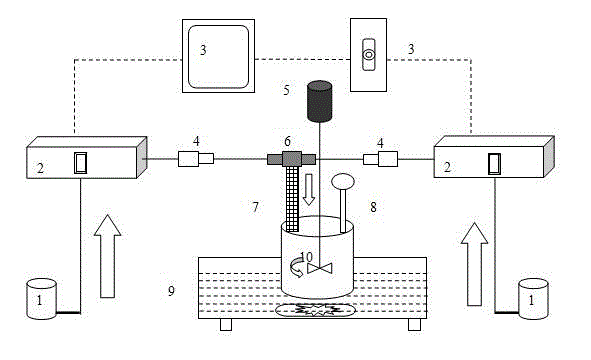

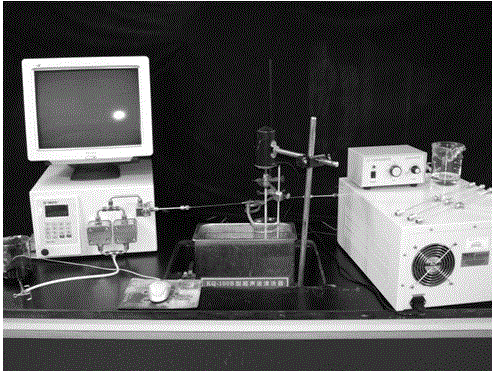

[0026] (2) In this experiment, the outlet pipe of the capillary impinging flow reactor was filled with three-dimensional mesh packing. Turn on the power supply of the two constant-current pumps, turn on the stirring paddle and the ultrasonic equipment, set the flow rate of the two pumps to 300 mL / min, and turn on the two pumps at the same time t...

Embodiment 2

[0030] (1) Weigh 15.8 g of analytical grade KMnO 4 Disperse evenly in deionized water to prepare a solution A with a concentration of 0.1 mol / L; accurately weigh 25.35 g of analytically pure grade MnSO 4 Dissolve in deionized water to prepare 0.15 mol / L solution B; inject the prepared solution into storage tanks A and B.

[0031] (2) In this experiment, no three-dimensional mesh structure was adopted in the capillary impact outflow outlet pipe. Set the flow rate of the two pumps to 300 mL / min, and turn on the two pumps at the same time through computer control, so that the pumps are filled with the reaction solution.

[0032] (3) Set the feed time to 16 s, and start the advection pump at the same time again, and the liquid enters the ultrasonic reactor after a strong impact, and the subsequent reaction is carried out for 30 min.

[0033] (4) The reaction product was washed, filtered under reduced pressure, and dried at 80°C for 12 h. The dried product was fully ground and st...

Embodiment 3

[0035] (1) 0.158 g of analytical grade KMnO 4 Disperse evenly in deionized water to prepare a solution A with a concentration of 0.001 mol / L; accurately weigh 0.2535 g of analytically pure grade MnSO 4 Dissolve in deionized water to prepare 0.0015 mol / L solution B; inject the prepared solution into storage tanks A and B.

[0036] (2) In this experiment, the three-dimensional mesh structure was not used in the capillary impingement outlet pipe, and the flow rate of the two pumps was set at 80 mL / min. Through software control, the two pumps were turned on at the same time to fill the pumps with the reaction solution.

[0037] (3) Set the feeding time to 1 min, and start the advection pump at the same time again, and the liquid enters the ultrasonic reactor after a strong impact, and the subsequent reaction is carried out for 30 min.

[0038](4) After washing and suction filtration, the reaction product was dried at 80°C for 12 h, and the dried product was fully ground and store...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com