Method and device for electrolytic oxidation reduction for self-cleaning composite graphite electrode

A composite graphite, electrolytic oxidation technology, applied in the field of electrochemical electrolysis, can solve the problems of rising current or voltage, affecting electrolysis efficiency, increasing power consumption, etc., to eliminate concentration polarization, avoid power consumption, and improve utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

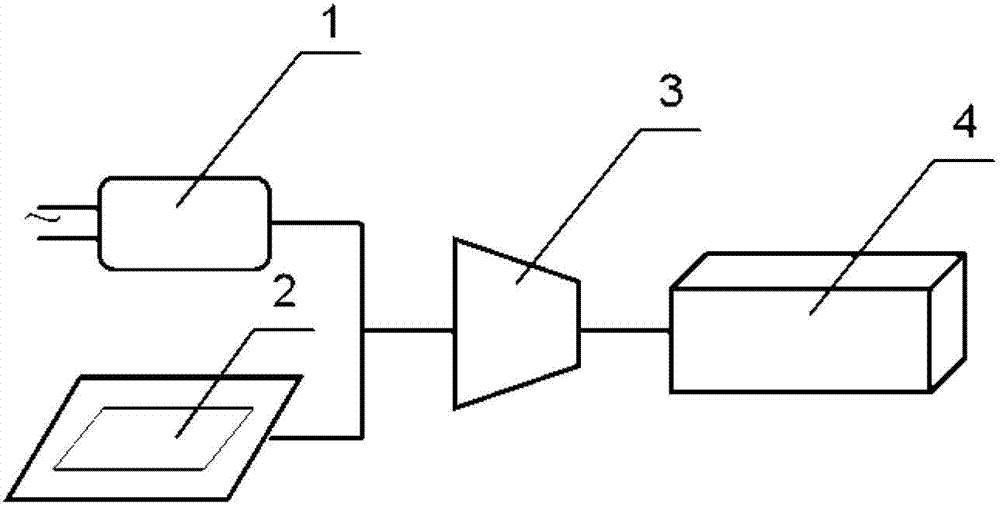

[0039] As shown in the attached figure, the self-cleaning composite graphite electrode electrolysis adopts a periodic steering electrolysis device. The electrolytic device includes: an electrolytic tank, a periodic steering controller, and a DC power supply system. The positive and negative electrodes of the electrolytic tank are insoluble metal stainless steel with a thickness of 3mm. It is a flat plate structure, with graphite repolarization in the middle, the outer diameter of the particles is about 1.5mm, and they are piled up in bulk. The distance between the insoluble metal electrode plates in the electrolytic cell is 10mm, and the distance between the graphite repolarization and the insoluble metal electrode plates in the middle is 1mm. Use plastic wire mesh to isolate, so that graphite repolarization and stainless steel electrodes cannot be in contact. The cycle steering controller realizes the cyclic operation of energization-disconnection-steering energization-disconn...

Embodiment 2

[0045] The difference from Example 1 is that the thickness of the stainless steel is 2 mm, the outer diameter of the graphite particles is about 3.5 mm, the distance between the electrode plates is 50 mm, and the distance between the graphite repolarization pole and the insoluble metal electrode plate in the middle is 2 mm.

[0046] Electrolysis method steps: 1) Use 15% sodium hydroxide solution to adjust the pH value to 7, and use sodium sulfate to adjust the conductivity to 0.7S / m; 2) The steering cycle is 80 seconds, and the ratio of disconnection time to power-on time is 1: 4; 3) Current density 10A / m 2 .

[0047]After 10 hours of electrolysis, the electrode was taken out, rinsed and dried with deionized water, and observed with an electron microscope at 5000 times. It can be seen that one side of the electrode is the same as the new electrode, and the other side has polymer adsorption. The positive and negative poles of the electrode are switched every 80 seconds, and on...

Embodiment 3

[0049] The difference from Example 1 is that the thickness of the stainless steel is 1.5 mm, the outer diameter of the graphite particles is about 5 mm, the distance between the electrode plates is 100 mm, and the distance between the graphite repolarization electrode and the insoluble metal electrode plate is 3 mm.

[0050] Electrolysis method steps: 1) Use 15% sodium hydroxide solution to adjust the pH value to 7, and use sodium sulfate to adjust the conductivity to 0.3S / m; 2) The steering cycle is 120 seconds, and the ratio of disconnection time to power-on time is 1: 2; 3) Current density 15A / m 2 .

[0051] After 4 hours of electrolysis, take out the material and replace it with a new one. After repeating 5 times, take out the electrode, rinse and dry it with deionized water, and observe it with an electron microscope at 5000 times. It can be seen that one side of the electrode is the same as the new electrode, and there is polymer on the other side. adsorption. The posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com