Preparation method of fluorobromoethylene

A technology of difluoroethylene and difluoroethane, applied in the fields of dehydrohalogenation preparation, organic chemistry, etc., can solve the problems of difficult acquisition of raw materials, high cost, and difficult industrial scale implementation, and achieve high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

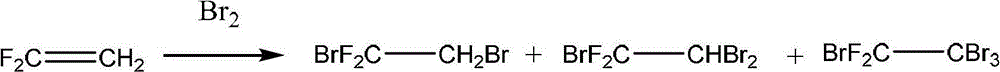

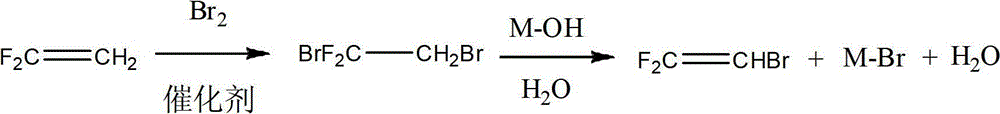

Method used

Image

Examples

Embodiment 1

[0056] 1. Preparation of 1,2-dibromo-1,1-difluoroethane

[0057] Add 10kg of bromine into a 10L reactor, heat it to 40°C, slowly feed 4.3kg of vinylidene fluoride, react for a total of 6 hours, and the reaction pressure is 0.3MPa. After the reaction, the excess vinylidene fluoride is collected in the recovery tank and separated It can be reused, and 14.09kg of the product 1,2-dibromo-1,1-difluoroethane was obtained from the reactor. The purity was 85.2% and the molar yield was 85.8% according to GC chromatography analysis.

[0058] After testing, the boiling point of the obtained product: 92.1°C / 760mmHg; mass spectrum MS molecular weight = 223.8; nuclear magnetic resonance NMR H 1 , chemical shift δ4.1; NMR F 19 , chemical shift δ-50.2.

[0059] 2. Preparation of 1-bromo-2,2-difluoroethylene

[0060] In 0.5m with -35℃ brine 2 Add 2kg of potassium hydroxide and 3kg of water into the 10L reaction kettle of the condenser with condensation area, heat to 60°C, and slowly feed 5...

Embodiment 2

[0063] 1. Preparation of 1,2-dibromo-1,1-difluoroethane

[0064] Add 10kg of bromine into a 10L reactor, heat it to 70°C, slowly feed 4.2kg of vinylidene fluoride, react for a total of 3 hours, and the reaction pressure is 0.2MPa. It can be reused, and 14.02kg of the product 1,2-dibromo-1,1-difluoroethane was obtained from the reaction kettle. After analysis, the purity was 86.5%, and the molar yield was 86.6%.

[0065] 2. Preparation of 1-bromo-2,2-difluoroethylene

[0066] In 0.5m with -35℃ brine 2 The 10L reactor of the condenser with the condensing area is transformed into a packed tower pipeline with a theoretical plate number of 20 in the pipeline from the rising steam to the condenser. Add 2kg of potassium hydroxide and 4kg of water to the reactor, heat it to 60°C, and slowly pass it into 5.5 kg of the above 96.5% purity 1,2-dibromo-1,1-difluoroethane was reacted for 5 hours in total, and 3.42 kg of the product was collected during the reaction, with a purity of 92.7%...

Embodiment 3

[0068] 1. Preparation of 1,2-dibromo-1,1-difluoroethane

[0069] Add 10kg of bromine into a 10L reactor, heat it to 60°C, slowly feed 4.3kg of vinylidene fluoride, react for a total of 4 hours, and the reaction pressure is 0.4MPa. It can be reused. A total of 14.03kg of the product 1,2-dibromo-1,1-difluoroethane was obtained from the reactor. The purity was 87.3% after analysis, and the molar yield was 87.5%.

[0070] 2. Preparation of 1-bromo-2,2-difluoroethylene

[0071] In 0.5m with -35℃ brine 2 The 10L reactor of the condenser with the condensing area is transformed into a packed tower pipeline with a theoretical plate number of 20 in the pipeline from the rising steam to the condenser. Add 2kg of potassium hydroxide, 3kg of water, and 0.5kg of ethanol to the reactor, and heat it to 60°C , 5.5kg of 1,2-dibromo-1,1-difluoroethane with a purity of 97% was slowly introduced, and the reaction lasted for 4 hours. During the reaction, 3.37kg of product was collected, with a pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com