Method for preparing water soluble chitosan oligosaccharide from squid sheath and bioactivity of chitosan oligosaccharide

A water-soluble chitosan oligosaccharide and squid sheath technology, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of low yield, corrosion equipment, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

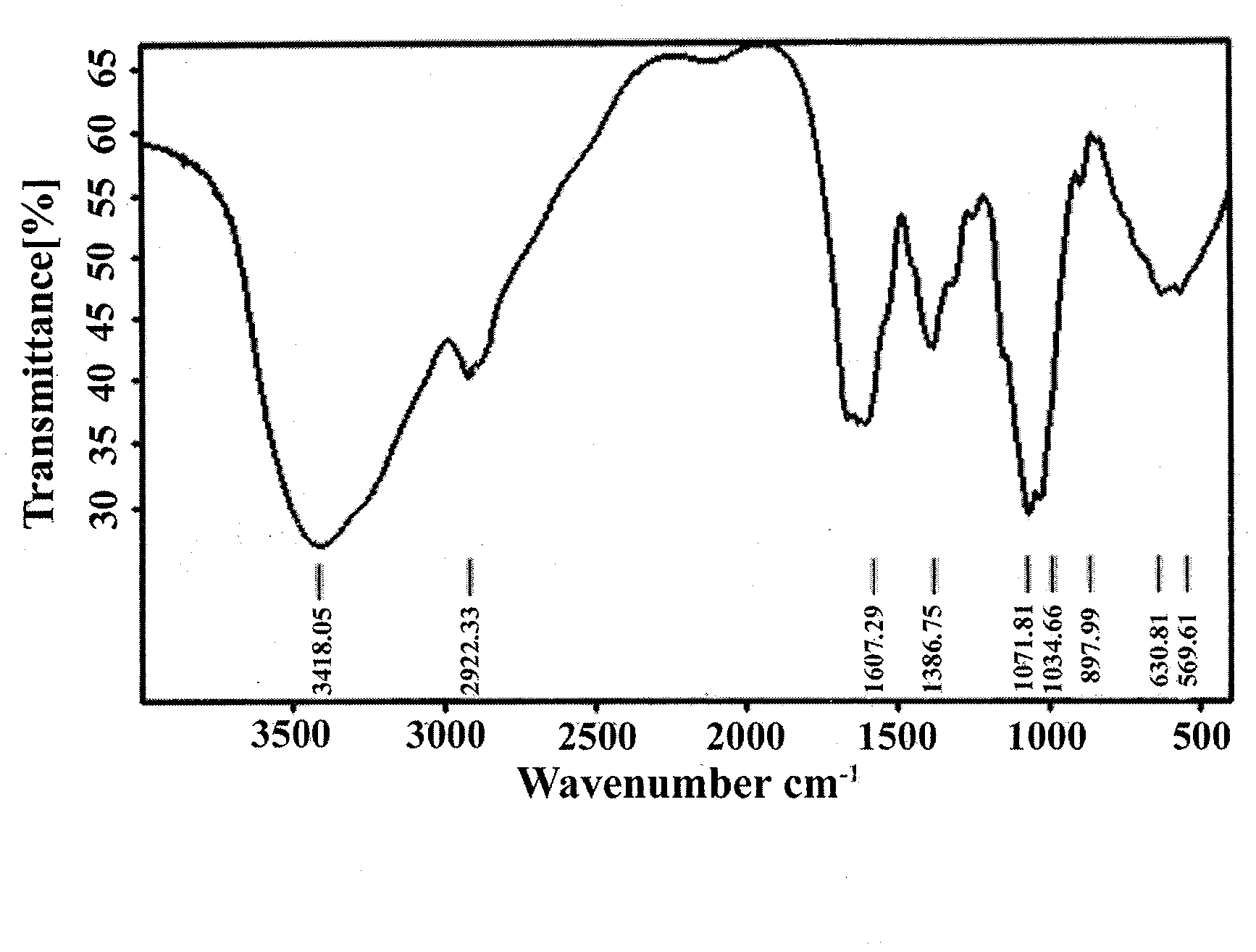

Image

Examples

Embodiment 1

[0023] Crush squid sheath into powder, weigh 400g of squid sheath powder, add 5600mL of 8% HCl solution, decalcify at room temperature for 30mmin, observe no bubbles, and wash until neutral. Then add 4000mL of 10% NaOH solution, deproteinize in a water bath at 100°C for 1 hour, filter and wash until neutral, dry at 60°C to obtain β-chitin, and crush it for use. Take 200g of β-chitin and add 2000mL of 50% HCl solution, ultrasonically react at 80°C for 2h, and ultrasonic frequency is 25KHz. After the reaction, filter with suction, and wash the filter cake to neutral chitosan. Take 40g chitosan, add 90mL 30% H 2 o 2 , and then add 810mL of distilled water to make H 2 o 2 The concentration is 3%, and it is reacted at 65°C for 4 hours under the assistance of ultrasonic waves, and the frequency is 40KHz. After the reaction is completed, it is adjusted to neutrality with NaOH, distilled under reduced pressure, so that the volume is concentrated to 1 / 10 of the original volume, and...

Embodiment 2

[0025] Crush the squid sheath into powder, weigh 400g of squid sheath powder, add 5600mL of 8% HCl solution, decalcify at room temperature for 30min, observe that no bubbles are generated, and wash until neutral. Then add 4000mL of 10% NaOH solution, deproteinize in a water bath at 100°C for 1 hour, filter and wash until neutral, dry at 60°C to obtain β-chitin, and crush it for use. Take 200g of β-chitin and add 2000mL of 50% HCl solution, ultrasonically react at 80°C for 2h, and ultrasonic frequency is 25KHz. After the reaction, filter with suction, and wash the filter cake to neutral chitosan. Take 40g chitosan, add 270mL 30% H 2 o 2 , and then add 630mL of distilled water to make H 2 o 2 The concentration is 9%, and the reaction is 4h at 65°C under the assistance of ultrasonic waves, and the frequency is 40KHz. After the reaction is completed, adjust to neutral with NaOH, distill under reduced pressure to make the volume concentrated to 1 / 10 of the original volume, and ...

Embodiment 3

[0027]Crush the squid sheath into powder, weigh 400g of squid sheath powder, add 5600mL of 8% HCl solution, decalcify at room temperature for 30mmin, observe that no bubbles are generated, and wash until neutral. Then add 4000mL of 10% NaOH solution, deproteinize in a water bath at 100°C for 1 hour, filter and wash until neutral, dry at 60°C to obtain β-chitin, and crush it for use. Take 200g of β-chitin and add 2000mL of 50% HCl solution, ultrasonically react at 80°C for 2h, and ultrasonic frequency is 25KHz. After the reaction, filter with suction, and wash the filter cake to neutral chitosan. Take 40g chitosan, add 180mL 30% H 2 o 2 , and then add 720mL of distilled water to make H 2 o 2 The concentration is 6%, and it is reacted at 45°C for 3 hours under the assistance of ultrasonic waves, and the frequency is 40KHz. After the reaction is completed, it is adjusted to neutrality with NaOH, distilled under reduced pressure, so that the volume is concentrated to 1 / 10 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com