Penicillium sp. mutant strain and application of penicillium sp. mutant strain to cellulase preparation

A cellulase and Penicillium oxalate technology, applied in the biological field, can solve the problems of high production cost, low cellulase activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

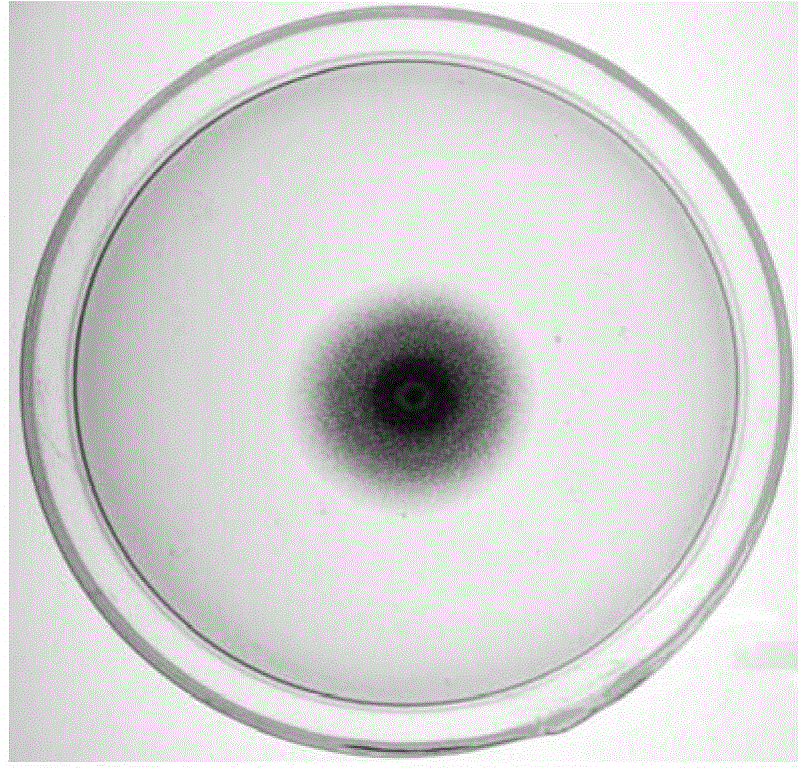

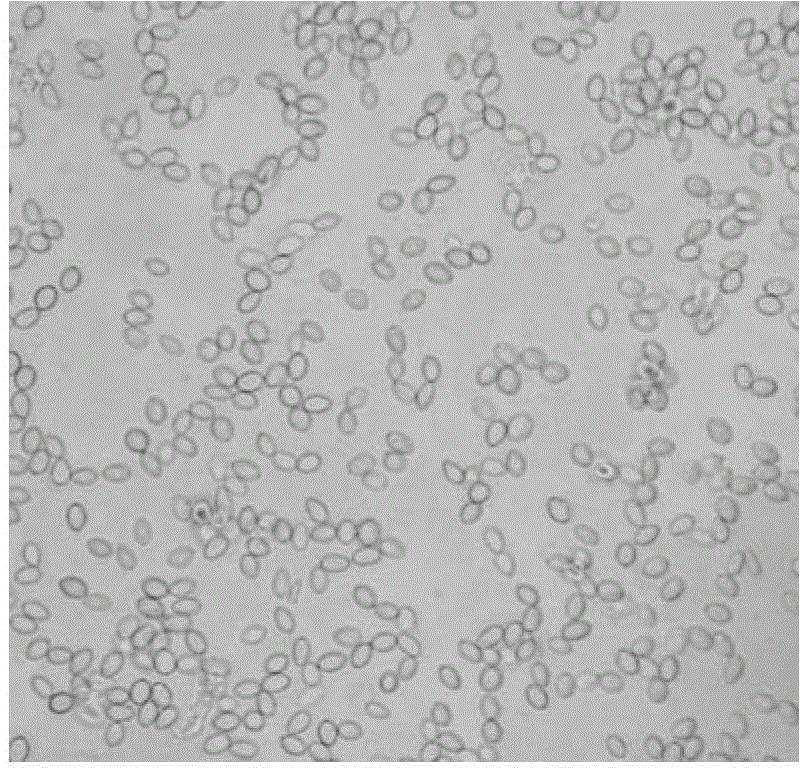

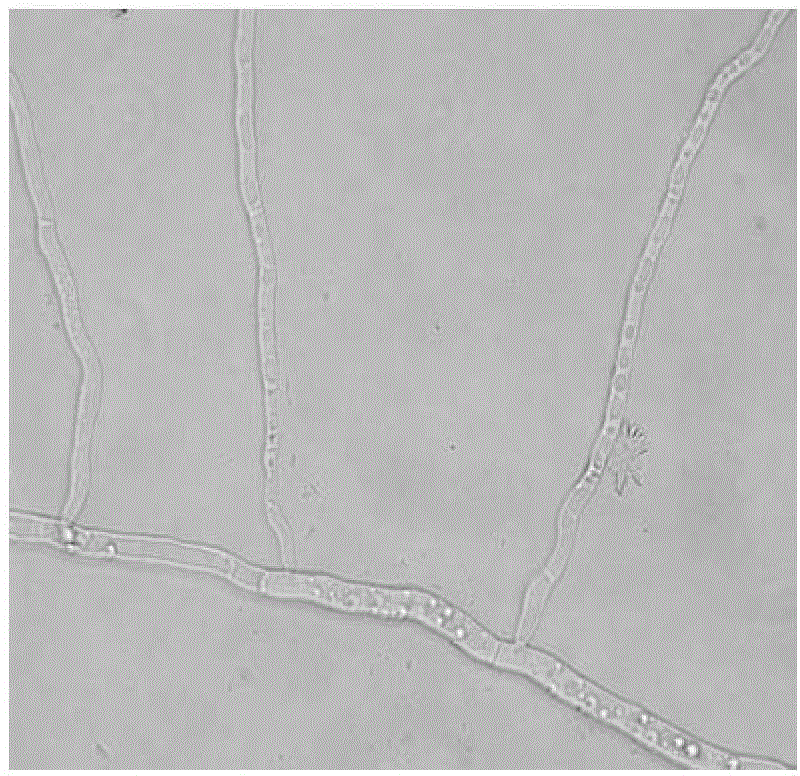

Image

Examples

Embodiment 1

[0048] In Example 1, the Congo red-Avicel solid medium used in the isolation and screening of mutant strains was (g / L): KH 2 PO 4 2g, (NH 4 ) 2 SO 4 1.4g, CaCl 2 0.3g, MgSO 4 .7H 2 O 0.5g, urea 0.3g, Yeast extract 0.8g, Peptone 2g, glucose 2g, Avicel PH-1013g, gelatin 2g, agar 20g, Congo red 0.2g, trace elements 0.05mL, pH 5.0, sterilized at 121°C for 30min.

[0049] When rescreening mutant strains, use liquid screening medium (g / L): KH 2 PO 4 4g, (NH 4 )2 SO 4 2.8g, CaCl 2 0.6g, urea 0.6g, MgSO 4 .7H 2 O 0.6g, wheat bran 20g, Avicel 30g, Tween-802mL, trace elements 0.1mL (the components of trace elements and the final concentration in the culture medium are respectively 5.0mg / LFeSO 4 ·7H 2 O,1.6mg / L MnSO 4 ·H 2 O,1.4mg / L ZnSO 4 ·7H 2 O, 2.0mg / L CoCl 2 ), pH 5.0, sterilized at 121°C for 30min.

[0050] When performing liquid shake flask re-screening on mutant strains, use the method of plate cutting, inoculate mycelium and spores (mycelia and spores with a ...

Embodiment 2

[0052] In Example 2, the enzymatic activities of various cellulases were measured by the following method.

[0053] 1) Glucose concentration standard curve

[0054] Prepare 1mg / mL glucose standard solution with deionized water. Add the solution into the test tube according to the formula in Table 1, mix well, develop color in boiling water for 5 minutes, and cool in cold water. Take 200 μL of the solution, add it to a 96-well microtiter plate, measure the absorbance at 540 nm, and draw a glucose standard curve. The regression equation is Y=3.1803X—0.0417, and the variance R 2 is 0.9992.

[0055] Table 1 Preparation of glucose concentration standard samples

[0056]

[0057] 2) Standard curve of p-nitrophenol (p-NP) concentration

[0058] Prepare 1 mg / mL p-NP standard solution with deionized water. Add the solution to the test tube according to the formula in Table 2. After mixing, draw 200 μL of the solution, put it in a 96-well microtiter plate, measure its absorbanc...

Embodiment 3

[0183] Example 3. Preparation of cellulase preparation (cellulase) using Penicillium sp. mutant strain EU2106

[0184] 1. Preparation of fermentation medium

[0185] Prepare an optimized medium for pH 5.5: KH 2 PO 4 4g, (NH 4 ) 2 SO 4 4g, CaCl 2 0.6g, MgSO 4 .7H 2 O0.6g, Tween-802mL, trace elements 0.1mL (the components of trace elements and the final concentration in the culture medium are respectively 5.0mg / L FeSO 4 ·7H 2 O,1.6mg / L MnSO 4 ·H 2 O,1.4mg / L ZnSO 4 ·7H 2 O,2.0mg / LCoCl 2 ), wheat bran 40g, Avicel 10g, pH adjusted with 2M HCl aqueous solution or 2M NaOH aqueous solution; distilled water to 1L; sterilized at 121°C for 30min.

[0186] 2. Preparation of spore solution

[0187] (1) Prepare PDA solid medium and sterilize it at 112°C for 20 minutes.

[0188] (2) Inoculate the Penicillium sp. mutant strain EU2106 on a PDA solid medium plate and culture it in a constant temperature incubator at 28°C for 5 days. Wash the spores with a certain volume of 0.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com