Breathing bag microbial-storage banana straw feed and preparation method thereof

A banana straw and breathing bag technology, applied in animal feed, animal feed, bags, etc., can solve the problems of increased breeding costs, vacuum exhaust, plastic bag damage, etc., and achieve the effect of stable structure, small volume, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

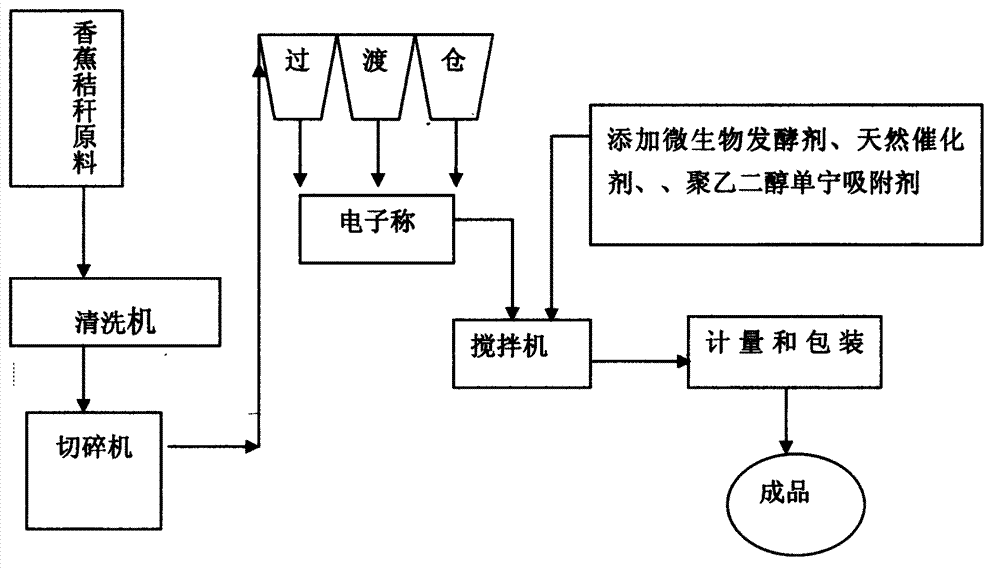

Method used

Image

Examples

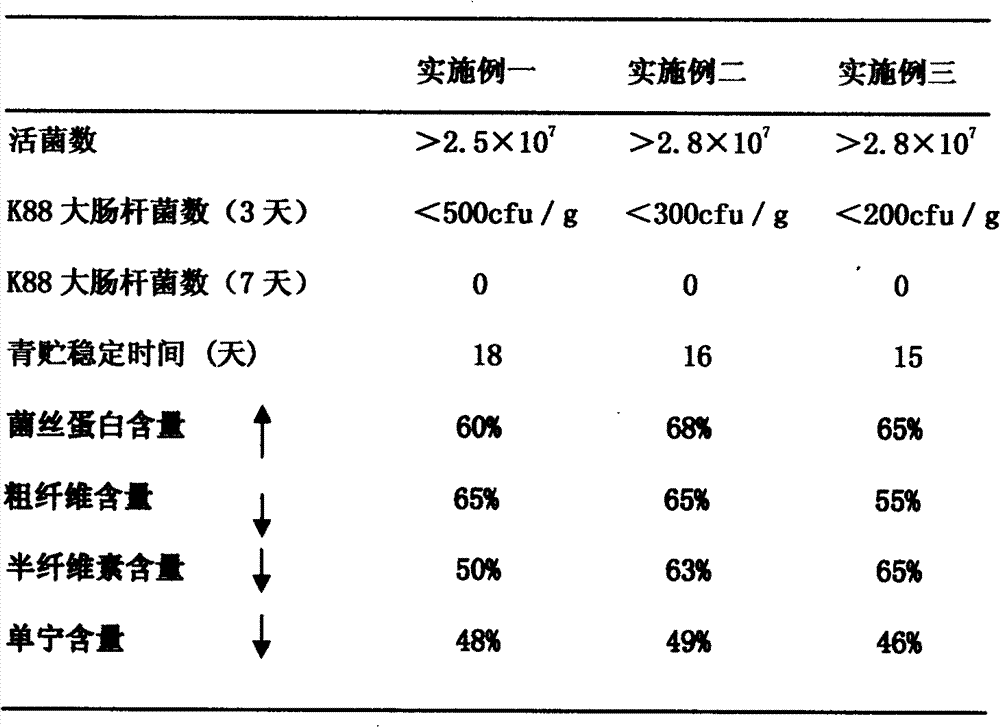

Embodiment 1

[0031] Use PA (polypropylene) / PE (Ninong) two kinds of polymer materials 7-9 layers of co-extruded film materials to make breathing bags, and press 5 breathing gas balance films on the surface of breathing bags, and the packaging thickness is 12 wires;

[0032]The parts by weight of the microbial fermentation agent contain 0.02% of saccharomyces, 0.03% of lactobacilli, and the number of live bacteria is > 2 × 10 7 The natural catalyst contains 0.01% of papain enzyme, 0.01% of pineapple enzyme, 0.01% of pectinase in its parts by weight, and the molecular weight of polyethylene glycol (PEG) tannin adsorbent is 200.

[0033] The preparation method of the micro-storage banana stalk feed in the breathing bag comprises the following steps:

[0034] (1) The raw materials are cleaned and sterilized, chopped and shredded into 2-3cm wide regular rod wires, and the water content of the banana stalks is adjusted to 60%;

[0035] (2) by the additive dispensing device, add 46 parts by weig...

Embodiment 2

[0040] Use PA (polypropylene) / PE (Ninong) two kinds of polymer materials 7-9 layers of co-extruded film materials to make breathing bags, press 6 breathing gas balance films on the surface of breathing bags, and pack 10 wires in thickness;

[0041] The parts by weight of the microbial fermentation agent contain 0.05% of saccharomyces and 0.06% of lactobacilli, and the number of live bacteria is > 2 × 10 7 The natural catalyst contains 0.05% papain, 0.05% pineapple and 0.05% pectinase in parts by weight of the natural catalyst, and the molecular weight of the polyethylene glycol (PEG) tannin adsorbent is 400.

[0042] The preparation method of the micro-storage banana stalk feed in the breathing bag comprises the following steps:

[0043] (1) The raw materials are cleaned and sterilized, chopped and shredded into regular rods with a width of 2-3cm, and the water content of the banana straw is adjusted to 65%;

[0044] (2) Through the additive dispensing device, add 25 parts by...

Embodiment 3

[0049] Use PA (polypropylene) / PE (Ninong) two kinds of polymer materials 7-9 layers of co-extruded film materials to make breathing bags, and press 8 breathing gas balance films on the surface of breathing bags, and the packaging thickness is 8 wires;

[0050] The parts by weight of the microbial fermentation agent contain 0.08% of saccharomyces, 0.09% of lactobacilli, and the number of viable bacteria > 2 × 10 7 The natural catalyst contains 0.09% papain, 0.09% pineapple and 0.09% pectinase in parts by weight of the natural catalyst, and the molecular weight of the polyethylene glycol (PEG) tannin adsorbent is 600.

[0051] The preparation method of the micro-storage banana stalk feed in the breathing bag comprises the following steps:

[0052] (1) The raw materials are cleaned and sterilized, chopped and shredded into regular rods with a width of 2-3cm, and the water content of the banana straw is adjusted to 65%;

[0053] (2) Through the additive dispensing device, add 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com