Gemini surfactant and preparation method thereof

A gemini surfactant and active agent technology, applied in the field of gemini surfactant and its preparation, can solve problems such as difficult to meet low temperature conditions, and achieve the effects of non-irritating skin and mucous membrane, strong water solubility, and product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

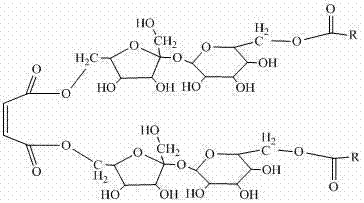

[0029] In a vacuum environment, put an organic solvent with a molar ratio of 6:1 to maleic anhydride in a four-necked flask; mix maleic anhydride and sucrose in a molar ratio of 1:2 in N,N-dimethylformamide in, then vacuum distillation; add maleic anhydride and 4% KOH of the total mass of sucrose solids as a catalyst; mix for 2 hours at 60°C; add methyl stearate to make the product in the organic solvent and the added ester Mixed at a molar ratio of 1: 2; dispersed at a temperature of 100°C for 1 hour; then heated up to 120°C, reacted for 2 hours to obtain a light yellow solid, and the product is of the structural formula:

[0030] nonionic gemini surfactants.

Embodiment 2

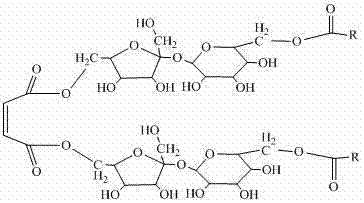

[0032] In a vacuum environment, put an organic solvent with a molar ratio of 8:1 to maleic anhydride in a four-necked flask; mix maleic anhydride and sucrose in a molar ratio of 1:2 in N,N-dimethylformamide 4% KOH of the total mass of maleic anhydride and sucrose solids was added as a catalyst; mixed for 2 hours at 60 ° C; methyl oleate was added to make the product in the organic solvent and the added ester press 1: 2 molar ratio mixing; Disperse at 110°C for 2 hours; Then heat up to 130°C, react for 2 hours to obtain a light yellow solid, the product is a structural formula:

[0033] nonionic gemini surfactants.

Embodiment 3

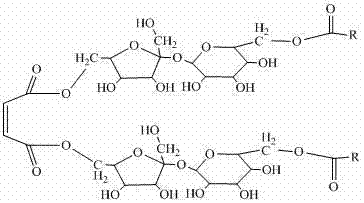

[0035] In a vacuum environment, put into the four-necked flask the organic solvent that the molar ratio with maleic anhydride is 5.6:1; Maleic anhydride and sucrose are mixed in toluene by the molar ratio of 1:2, then underpressure distillation; Add 4% NaOH of maleic anhydride and sucrose solid gross mass is used as catalyst; Mixed 3 hours under 70 ℃; Add methyl stearate, make the product in the organic solvent and the added ester mix by 1: 2 molar ratio ; Disperse for 2 hours at a temperature of 100°C; then heat up to 120°C and react for 3 hours to obtain a light yellow solid, and the product is of structural formula

[0036] nonionic gemini surfactants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com