Preparation method for direct methanol fuel cell supported Pt-based anode catalyst

A methanol fuel cell, load-type technology, applied in the direction of battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult polymerization reaction conditions, excessive particle size, weak electron conductivity, etc., and meet the conditions Good controllability, simple process, and the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 0.1g of 5-20nm graphene microchips into 100ml of deionized water, sonicate for 2 hours in a cell pulverizer, and filter through a filter membrane; the graphene obtained after filtration is dissolved in 200ml of N-methylpyrrolidone, magnetically stirred at room temperature for 3 minutes, and ultrasonicated for 2 hours. Obtain the dispersion liquid of graphene; 2.04mg polyaniline joins 10mlN-methylpyrrolidone solvent; Obtain the N-methylpyrrolidone solution of polyaniline, mix the N-methylpyrrolidone solution of 200ml graphene dispersion liquid and 10ml polyaniline, Stir magnetically for 24 hours; filter with a filter membrane, dissolve the filter cake in a mixed solution of 50ml deionized water and 300ml ethylene glycol, stir, ultrasonicate for 1 hour, add 13.06ml of 0.1M chloroplatinic acid solution, and wait until the temperature rises to 125°C, react for 4h. Lower the temperature to room temperature, filter, and wash the filter cake with deionized water and ethano...

Embodiment 2

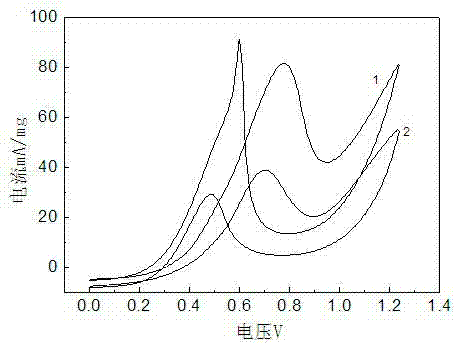

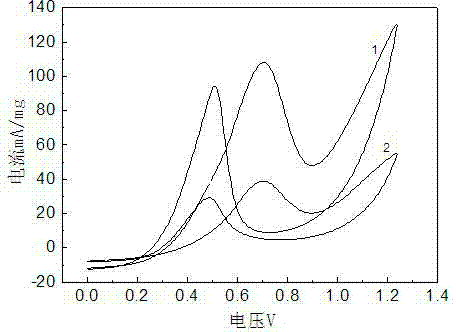

[0021] The other conditions of this example are the same as those of Example 1, except that the 5-20 nm graphene microflakes are changed to 1-5 nm graphene nano-sheets to obtain a Pt / polyaniline-graphene catalyst with a particle size of 2-3 nm. Take 3 mg of the catalyst and dissolve it in ethanol and Nafion solvent, and then apply it on carbon paper as an anode. At a potential of 0-1.24 V and a scan rate of 10 mV / s, the cyclic volts of methanol oxidation were measured by a simulated fuel cell. The safety curve diagram is attached figure 1 and attached figure 2 As shown, it can be seen from the figure that the performance of the catalyst of the present invention is significantly better than that of the catalysts prepared in Comparative Example 1 and Comparative Example 2.

Embodiment 3

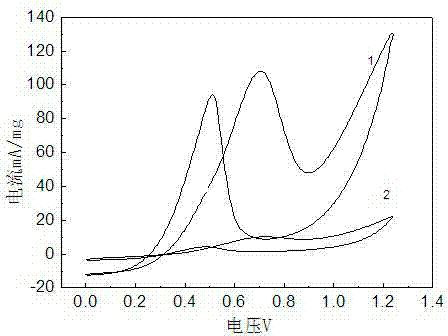

[0023] Dissolve 0.1g of 1-5nm graphene nanosheets in 100ml of deionized water, sonicate for 2 hours in a cell pulverizer, and filter; dissolve the obtained graphene in 200ml of N-methylpyrrolidone, stir mechanically, and ultrasonically for 2 hours, add 25mg of polyaniline to 10ml of N -In the methylpyrrolidone solution, mix 200ml of the dispersion with 10ml of the N-methylpyrrolidone solution of polyaniline, stir for 12 hours; filter, and dissolve the filter cake in a 1:4 mixed solution of deionized water and ethylene glycol, Stir and sonicate, add 16ml of chloroplatinic acid with a concentration of 0.1M, wait until the temperature rises to 125°C, and react for 4h. The temperature was lowered to room temperature, the precipitate was washed with deionized hydrated ethanol, filtered, and vacuum-dried at 75° C. to obtain a Pt / polyaniline-graphene catalyst with a particle size of 2-3 nm. Take 3 mg of the catalyst and dissolve it in ethanol and Nafion solvent, and then apply it on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com