Tellurium dioxide purification method

A purification method, the technology of tellurium dioxide, which is applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems such as the reduction of arsenic and selenium impurities, the excessive amount of sodium sulfide, and the yellowing of the product, so as to achieve simple and clear process and recovery The effect of improving the efficiency and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

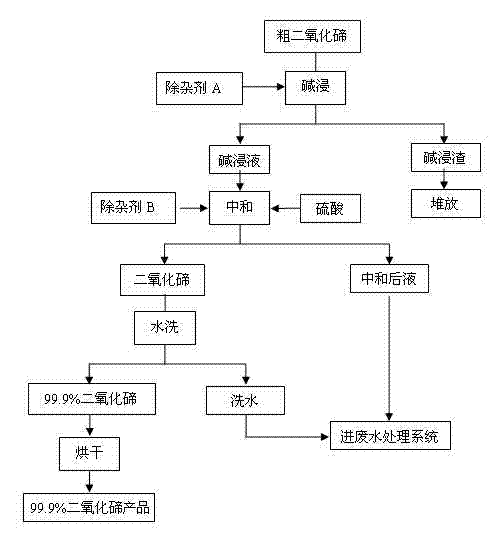

Method used

Image

Examples

Embodiment 1

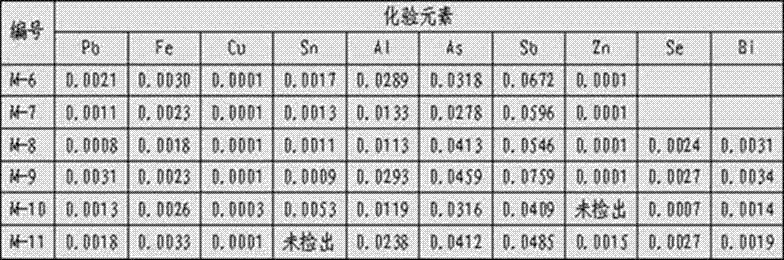

[0019] Embodiment one: the raw material is tellurium dioxide with a content of 99.5%. The raw material composition is as attached table 1. From the attached table 1, it can be seen that the impurity components antimony, arsenic, aluminum, and silicon are relatively high, and other elements are relatively low. If you want to make the product The main component exceeds 99.9%, so we must find ways to reduce these four impurity elements.

[0020] This test is a small-scale test. The equipment used includes small stirrers, stainless steel cups and glass beakers, plastic stirring rods, vacuum pumps and other equipment. In this test, all utensils have been soaked in hydrochloric acid or brand new beakers to avoid damage to the product. Quality makes a difference.

[0021] Sodium sulfide lead removal condition test.

[0022] Adding a small amount of sodium sulfide to the sodium tellurite solution can remove the lead in the solution, but the amount of sodium sulfide must not be excess...

Embodiment 2

[0029] Example 2: The condition test of impurity remover A and impurity remover B in combination.

[0030] In order to test the combined effect of these two impurity removers. This condition test is mainly to test the effect of joint impurity removal. 99.5% of the product is used as the test raw material, and lead, arsenic, antimony, and copper are used as the investigation objects. The content of lead, arsenic, antimony, copper, and iron in the raw material is 0.065% respectively. . It can be seen that among the five impurity elements, the removal rate of lead is the highest, the removal rate of copper is the second, and the removal rate of antimony is the lowest.

[0031] Table 3 Results of combined impurity removal condition test of impurity remover A and impurity remover B

[0032]

[0033] Through the above condition test, the best technical conditions determined are: impurity remover A is 2% of the raw material amount, impurity remover B is 4% of the raw material am...

Embodiment 3

[0034] Embodiment 3: whole process test.

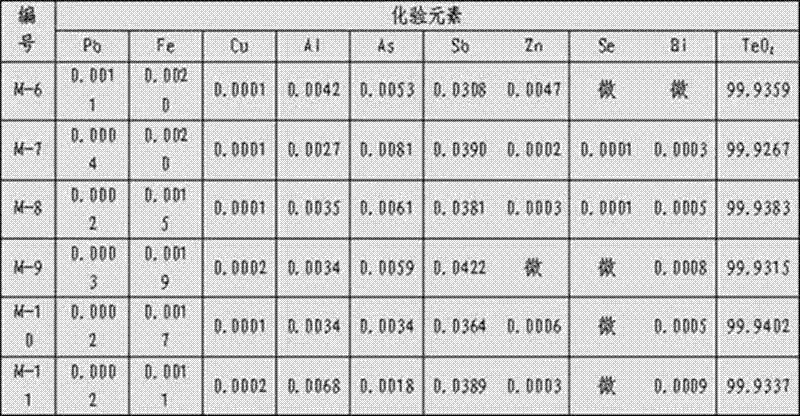

[0035] The results of the whole process test show that the following methods can be used to treat and purify tellurium dioxide, which can reduce ten elements of impurity elements lead, iron, copper, aluminum, arsenic, zinc, cobalt, selenium, bismuth and sulfur to a relatively low level, antimony and silicon The content of the two impurities is relatively high.

[0036] Table 4 is the raw material composition table of trial production of 99.9% tellurium dioxide;

[0037] Table 5 is the composition list of 99.9% tellurium dioxide in the whole process test;

[0038] Table 6 Metal balance table of tellurium dioxide purified and processed tellurium.

[0039] In the trial production process, 99.5% of tellurium dioxide was input, and 99.9% of tellurium dioxide was produced, leaching

[0040] Slag, solution after tellurium precipitation, washing water, because tellurium dioxide products are insoluble in water, so the tellurium content in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com