Cerium-doped lead dioxide electrode, and preparation method and application thereof in quick decolorization and efficient mineralization of basic dyes

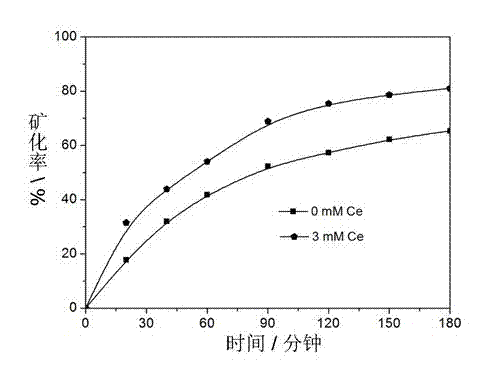

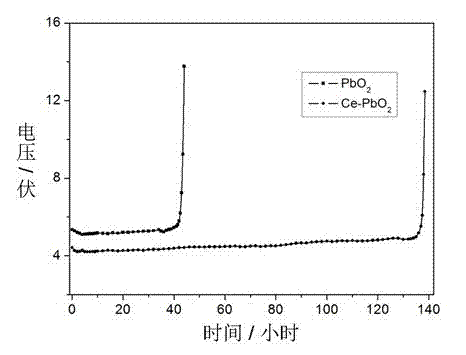

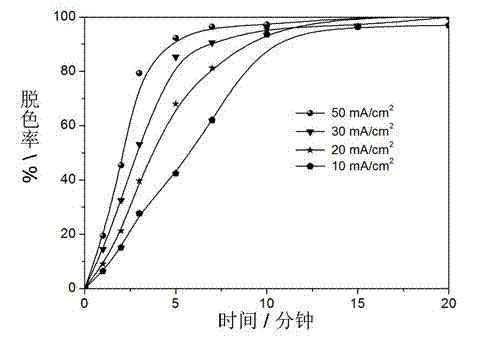

A lead dioxide and cerium doping technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of slow treatment process, many intermediate products, long process flow, etc. Achieve the effects of rapid decolorization, increased service life and strong catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Grind the titanium plate with coarse and fine sandpaper to make the surface of the titanium plate show a uniform light gray luster.

[0034] 2) Immerse the polished titanium plate in a 40 wt% NaOH solution, and wash it in alkali at 80 ℃ for 2 hours to remove grease and other contaminants on the surface of the titanium plate.

[0035] 3) The alkali-washed titanium plate is immersed in 15 wt% oxalic acid solution and pickled at 90 ℃ for 2 hours to remove TiO 2 .

[0036] 4) The acid-washed titanium plate is used as the anode, the Pt electrode is the cathode, and the electrolyte is composed of 0.8 wt% NaF and 1.6 wt% Na 2 SO 4 , 10 wt% polyethylene glycol and ultrapure water, etched at a constant pressure of 20 V for 3 hours, and then calcined in a muffle furnace at 500 ℃ for 1.5 hours.

[0037] 5) Use Pt electrode as anode and calcined titanium plate as cathode, 1 mol / L (NH 4 ) 2 SO 4 It is an electrolyte, which is energized at a constant voltage of 1.5 V for 20 seconds.

[0038...

Embodiment 2

[0043] 1) Grind the titanium plate with coarse and fine sandpaper to make the surface of the titanium plate show a uniform light gray luster.

[0044] 2) Immerse the polished titanium plate in a 30 wt% NaOH solution, and wash it with alkali at 90 ℃ for 3 hours to remove grease and other contaminants on the surface of the titanium plate.

[0045] 3) The alkali-washed titanium plate is immersed in a 10 wt% oxalic acid solution and pickled at 95 ℃ for 4 hours to remove TiO on the surface of the titanium plate 2 .

[0046] 4) The pickled titanium plate is used as the anode, the Pt electrode is the cathode, and the electrolyte is composed of 0.5 wt% NaF and 1 wt% Na 2 SO 4 , 5 wt% polyethylene glycol and ultrapure water, etched at a constant pressure of 15V for 3 hours, and then calcined in a muffle furnace at 500 ℃ for 3 hours.

[0047] 5) Use Pt electrode as anode and calcined titanium plate as cathode, 0.5 mol / L (NH 4 ) 2 SO 4 It is an electrolyte, which is energized at a constant voltag...

Embodiment 3

[0053] 1) Grind the titanium plate with coarse and fine sandpaper to make the surface of the titanium plate show a uniform light gray luster.

[0054] 2) Immerse the polished titanium plate in a 50 wt% NaOH solution, and wash it in alkaline at 70 ℃ for 1 hour to remove grease and other contaminants on the surface of the titanium plate.

[0055] 3) The alkali-washed titanium plate is immersed in 20 wt% oxalic acid solution and pickled at 80 ℃ for 3 hours to remove TiO on the surface of the titanium plate 2 .

[0056] 4) The acid-washed titanium plate is used as the anode, the Pt electrode is the cathode, and the electrolyte is composed of 2 wt% NaF and 5 wt% Na 2 SO 4 , 20 wt% polyethylene glycol and ultrapure water, etched at a constant pressure of 25V for 1 hour, and then calcined in a muffle furnace at 500 ℃ for 3 hours.

[0057] 5) Use the Pt electrode as the anode and the calcined titanium plate as the cathode, 1.5 mol / L (NH 4 ) 2 SO 4 It is an electrolyte, which is energized at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com