Water-based floor alkali-resistant sealing primer

A technology for sealing primers and floors, which is applied in the field of floor paints to achieve the effects of fast drying, high water vapor transmission rate, and reduced foaming and cracking of paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

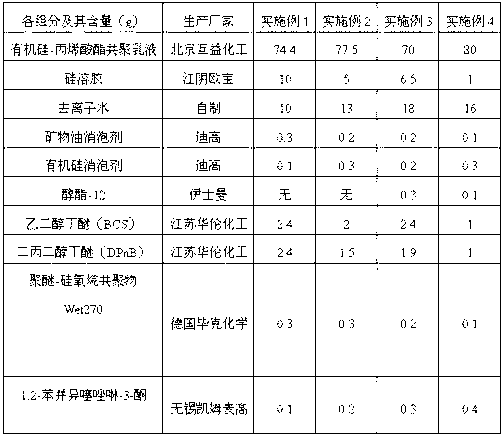

[0033] The preparation technology of water-based floor anti-alkali sealing primer in embodiment 1~2 is as follows:

[0034] Weigh each component as shown in Table 1, first put the silicone-acrylate copolymer emulsion, silica sol and deionized water into the mixer in turn, stir at 400-500 rpm for 10 min, and put them in the stirring state Ethylene glycol butyl ether (BCS) and dipropylene glycol butyl ether (DPnB), continue stirring for 10 min, then add mineral oil defoamer, silicone defoamer and polyether-siloxane copolymer Wet270, at 500-600 Stir at rpm for 10 min, finally add 1,2-benzisothiazolin-3-one, and stir at 500-600 rpm for another 10 min to obtain a finished water-based floor anti-alkali sealing primer.

[0035] The preparation process of the water-based floor anti-alkali sealing primer in Examples 3 to 4 is the same as above, except that the alcohol ester- 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com