Multi-effect semi-synthetic cutting solution

A semi-synthetic, cutting fluid technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of poor biodegradability and large environmental pollution, and achieve the effects of good environmental protection, good biological stability and not easy to stink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

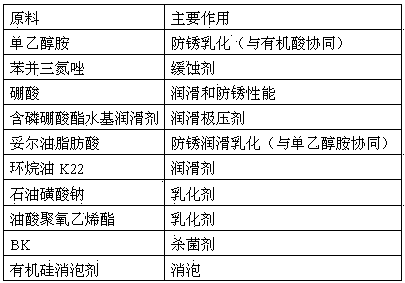

Method used

Image

Examples

Embodiment 1

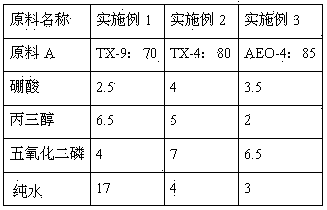

[0042] First prepare the phosphorus-containing borate water-based lubricant:

[0043] (1) Put boric acid, raw material A, and glycerol into the reaction kettle, and conduct the reaction under vacuum and constant stirring. The reaction temperature is 80°C and the reaction time is 120 minutes;

[0044] (2) Turn off the vacuum, cool the temperature in the reactor to below 50℃, then slowly add phosphorus pentoxide to the reactor, keep stirring, control the reaction temperature below 90℃, and stir for 1 hour after the addition is complete;

[0045] (3) Control the temperature below 90℃, add pure water to the reactor and stir for 60 minutes;

[0046] (4) The temperature of the reactor is lowered to room temperature, and the material is discharged to obtain a phosphorus-containing borate water-based lubricant.

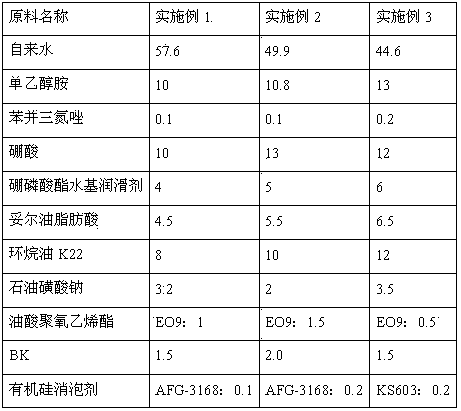

[0047] Then mix monoethanolamine, benzotriazole, boric acid, phosphorus-containing borate water-based lubricant, tall oil fatty acid, naphthenic oil K22, sodium petroleum sulfonate, po...

Embodiment 2

[0049] First prepare the phosphorus-containing borate water-based lubricant:

[0050] (1) Put boric acid, raw material A, and glycerol into the reaction kettle, and conduct the reaction under vacuum and continuous stirring. The reaction temperature is 120°C and the reaction time is 60 minutes;

[0051] (2) Turn off the vacuum, cool the temperature in the reactor to below 50℃, then slowly add phosphorus pentoxide to the reactor, keep stirring, control the reaction temperature below 90℃, and stir for 50 minutes after the addition is complete;

[0052] (3) Control the temperature below 90℃, add pure water to the reactor and stir for 70 minutes;

[0053] (4) The temperature of the reactor is lowered to room temperature, and the material is discharged to obtain a phosphorus-containing borate water-based lubricant.

[0054] Then mix monoethanolamine, benzotriazole, boric acid, phosphorus-containing borate water-based lubricant, tall oil fatty acid, naphthenic oil K22, sodium petroleum sulfona...

Embodiment 3

[0056] First prepare the phosphorus-containing borate water-based lubricant:

[0057] (1) Put boric acid, raw material A, and glycerol into the reaction kettle, and conduct the reaction under vacuum and constant stirring. The reaction temperature is 100°C and the reaction time is 100 minutes;

[0058] (2) Turn off the vacuum, cool the temperature in the reactor to below 50℃, then slowly add phosphorus pentoxide into the reactor, keep stirring, control the reaction temperature below 90℃, and stir for 70 minutes after the addition is complete;

[0059] (3) Control the temperature below 90℃, add pure water to the reactor and stir for 80 minutes;

[0060] (4) The temperature of the reactor is lowered to room temperature, and the material is discharged to obtain a phosphorus-containing borate water-based lubricant.

[0061] Then mix monoethanolamine, benzotriazole, boric acid, phosphorus-containing borate water-based lubricant, tall oil fatty acid, naphthenic oil K22, sodium petroleum sulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com