Enteric-coated capsule containing cationic nanoparticles for oral insulin delivery

A nanoparticle and enteric coating technology, which is applied in capsule delivery, powder delivery, freeze-drying delivery, etc., can solve the problems of reducing the stability of nanoparticles and reducing the positive charge characteristics of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Cationic Nanoparticles Loaded with Insulin

[0028] Nanoparticles were prepared by multiple emulsification technique. Briefly, 1 mL of aqueous insulin solution (1 mg / mL) was first emulsified in dichloromethane (5 mL) containing 100 mg of polymer (PLGA / Eudragit RS, 50 / 50) by sonication at a power of 40 W for 30 s. The obtained first emulsion was then poured into 40 mL of polyvinyl alcohol aqueous solution (1%) and sonicated with a power of 60 W for 1 min, so that multiple emulsions were formed. After dichloromethane was evaporated under reduced pressure, nanoparticles were collected by centrifugation at 20,000 rpm for 10 minutes and washed three times. After pre-freezing the resulting dispersion overnight at -20°C (nanoparticle and cryoprotectant concentrations of 1% and 1.5%, respectively), the mixture was then vacuum lyophilized.

[0029] Table 1

[0030]

[0031]

[0032] Δ: Precipitation / aggregation of nanoparticles was observed.

[0033] The...

Embodiment 2

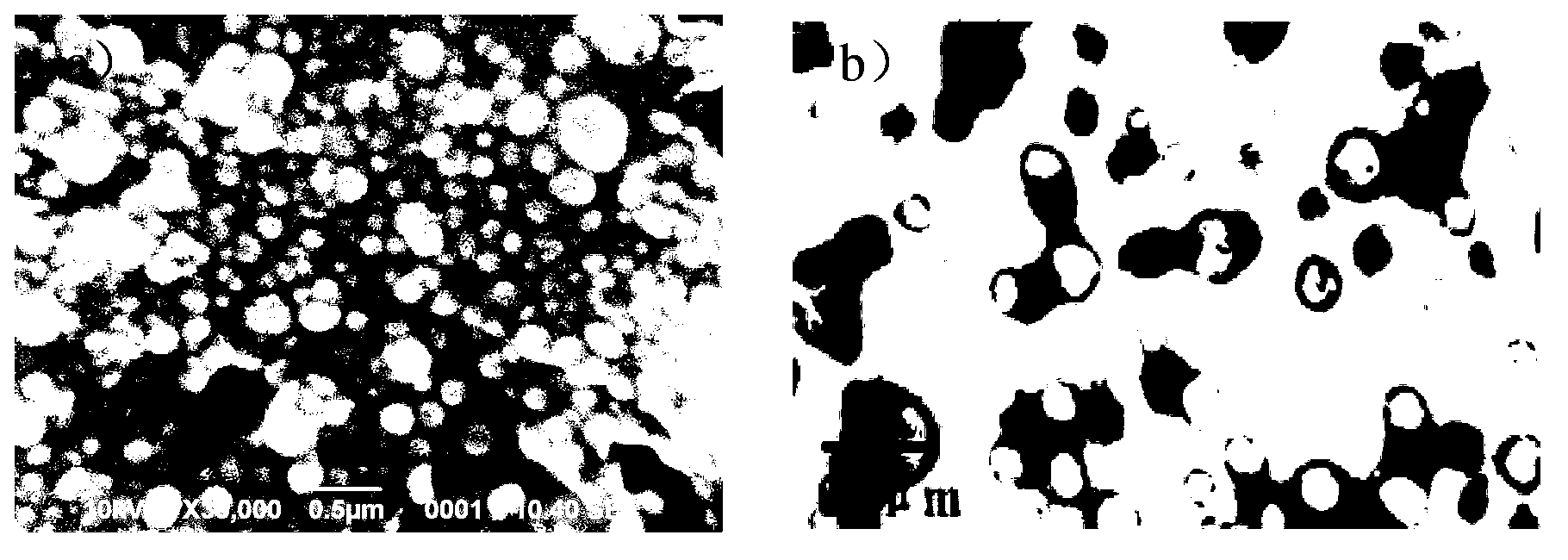

[0035] Characterization of insulin-loaded cationic nanoparticles

[0036] In general, nanoparticles have greater cellular uptake than microparticles and are more readily available for wider uptake due to their smaller size and greater fluidity. Reducing the nanoparticle size results in increased absorption of insulin by enterocytes. Many formulation and process parameters affecting nanoparticle size, such as sonication time, polymer amount, surfactant concentration, and volume of oil phase and external aqueous phase, etc., were investigated in the multiple emulsion solvent evaporation method in the present invention. Changing the volume of the external aqueous phase is considered to be the easiest way to adjust the size of the nanoparticles of the invention. As shown in Table 2, reducing the volume of the external aqueous phase can reduce the size of the nanoparticles and increase the zeta potential value of the nanoparticles. The smaller the volume of the outer aqueous phas...

Embodiment 3

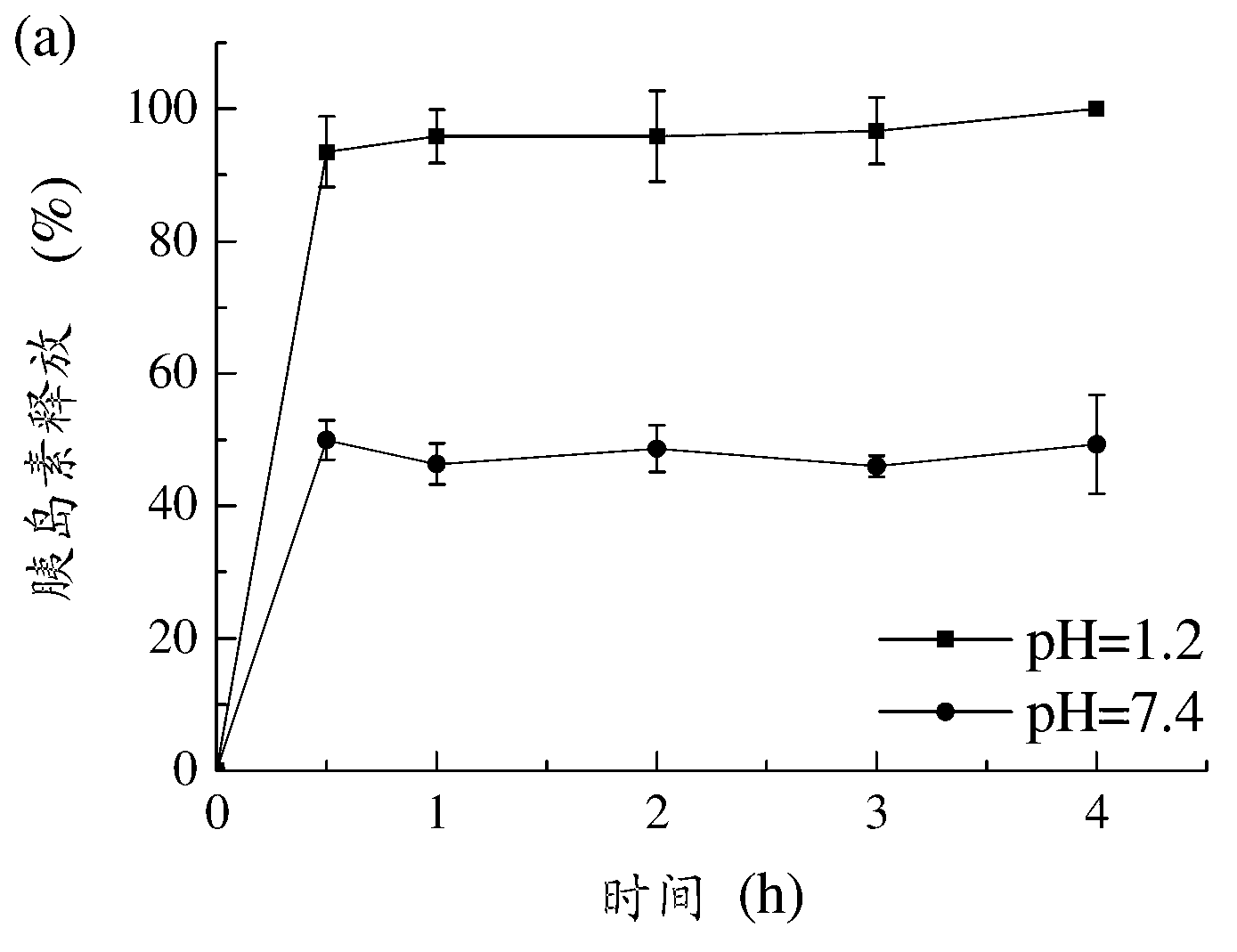

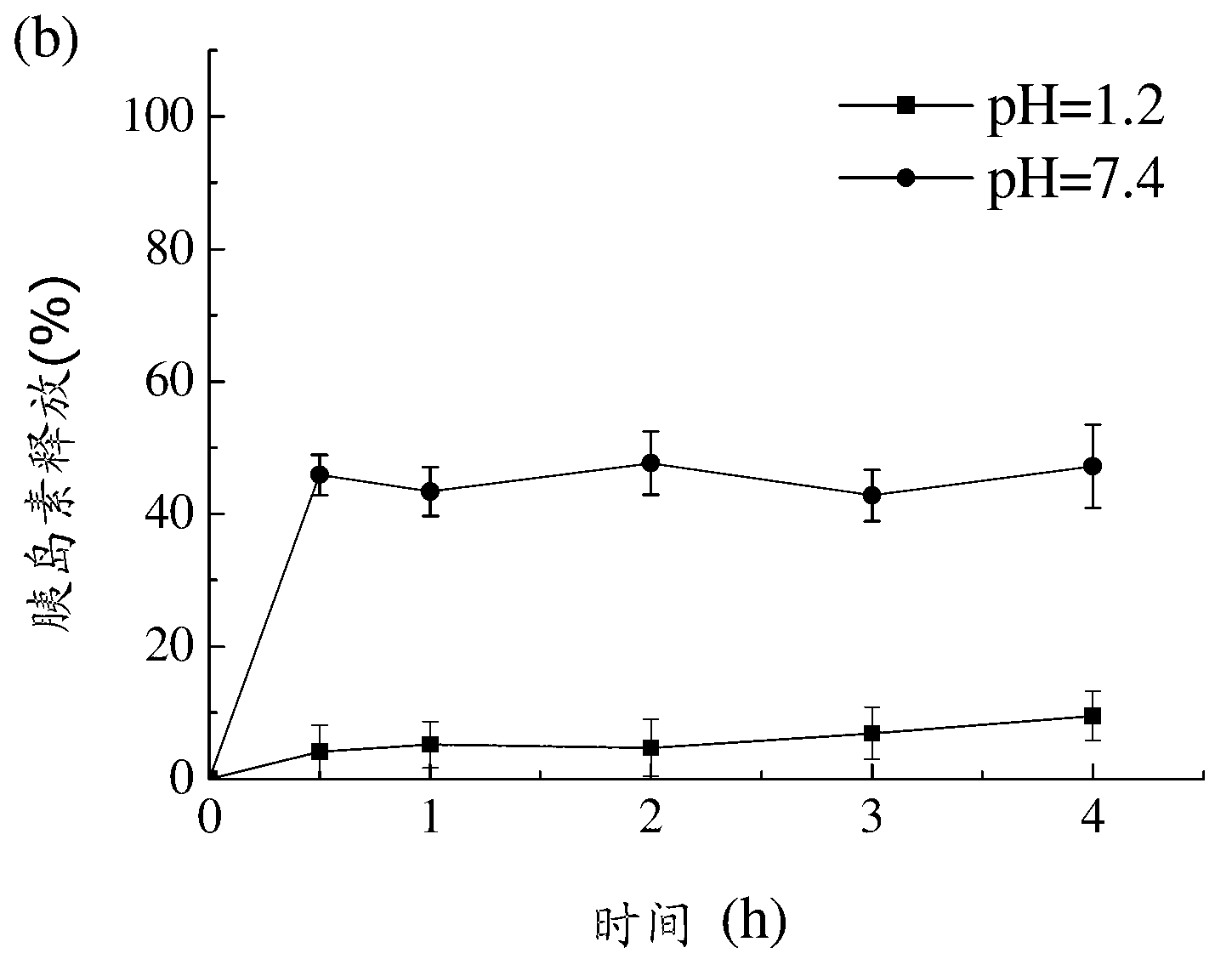

[0041] Zeta potential of PLGA / RS nanoparticles under different pH conditions

[0042] The zeta potential value is an important particle property as it can affect both nanoparticle stability and mucoadhesion under GI conditions. Positive zeta potential values can promote mucoadhesion. The mucosal layer itself is at neutral pH with anionic polyelectrolytes. Therefore, the presence of positively charged groups on the nanoparticles can induce charge interactions between the mucosa and the particles. As shown in Table 3, the zeta potential values and sizes of PLGA / RS nanoparticles have been investigated in the pH range of 1.2-7.2, which mimics GI physiological conditions. Obviously the pH value of the medium has an important effect on the zeta potential value of the nanoparticles. In general, quaternary ammonium cations in RS polymers are permanently charged independent of the pH of their solutions. Insulin (PI=5.4) becomes a positively charged molecule at pH 1.2. Theoreti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com