Titanium dioxide/silver/silver bromide core-shell photocatalyst and preparation method thereof

A titanium dioxide, core-shell structure technology, applied in the field of photocatalysis, can solve the problems of long preparation period, complex process, single preparation method, etc., and achieve the effect of short preparation period, low reaction temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

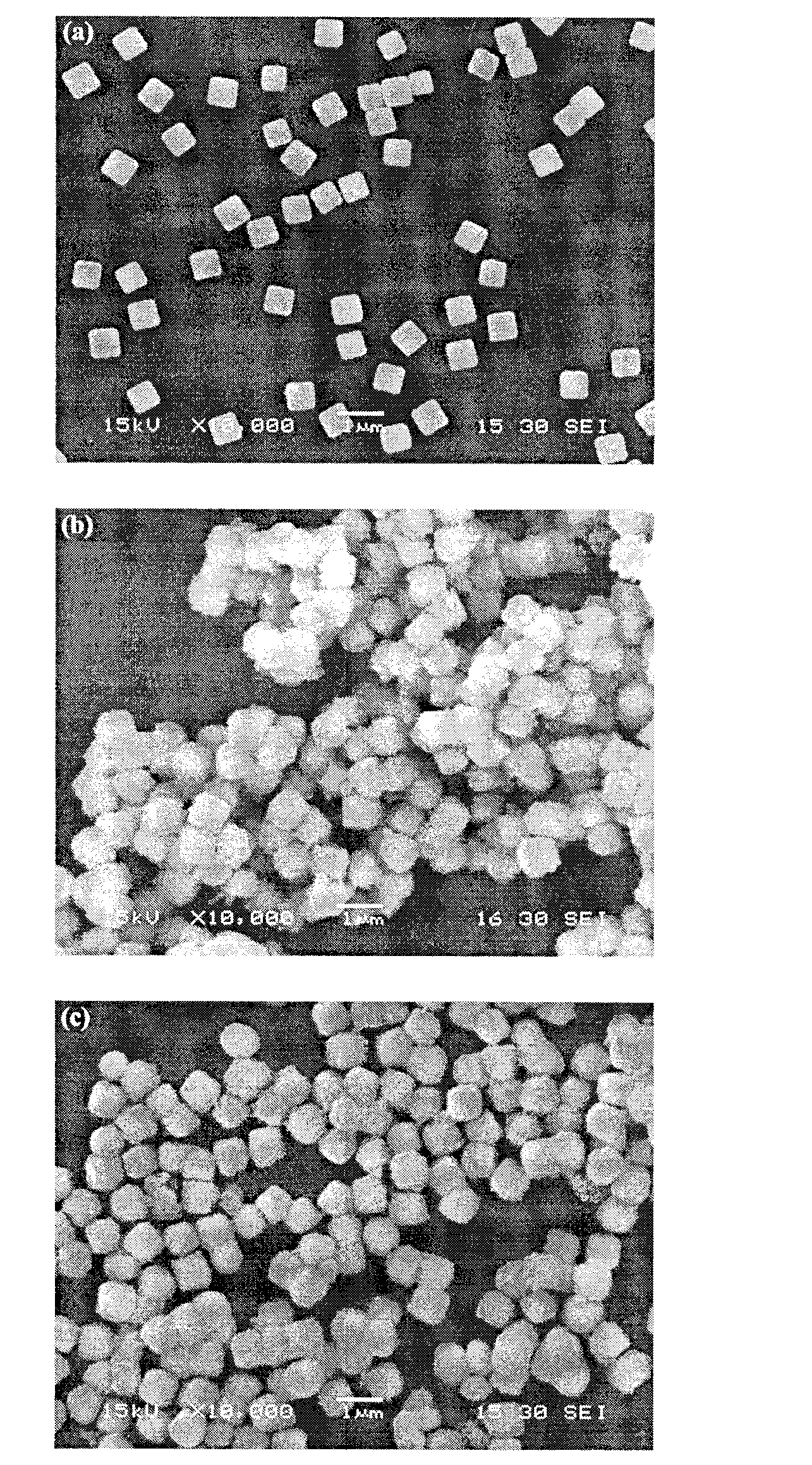

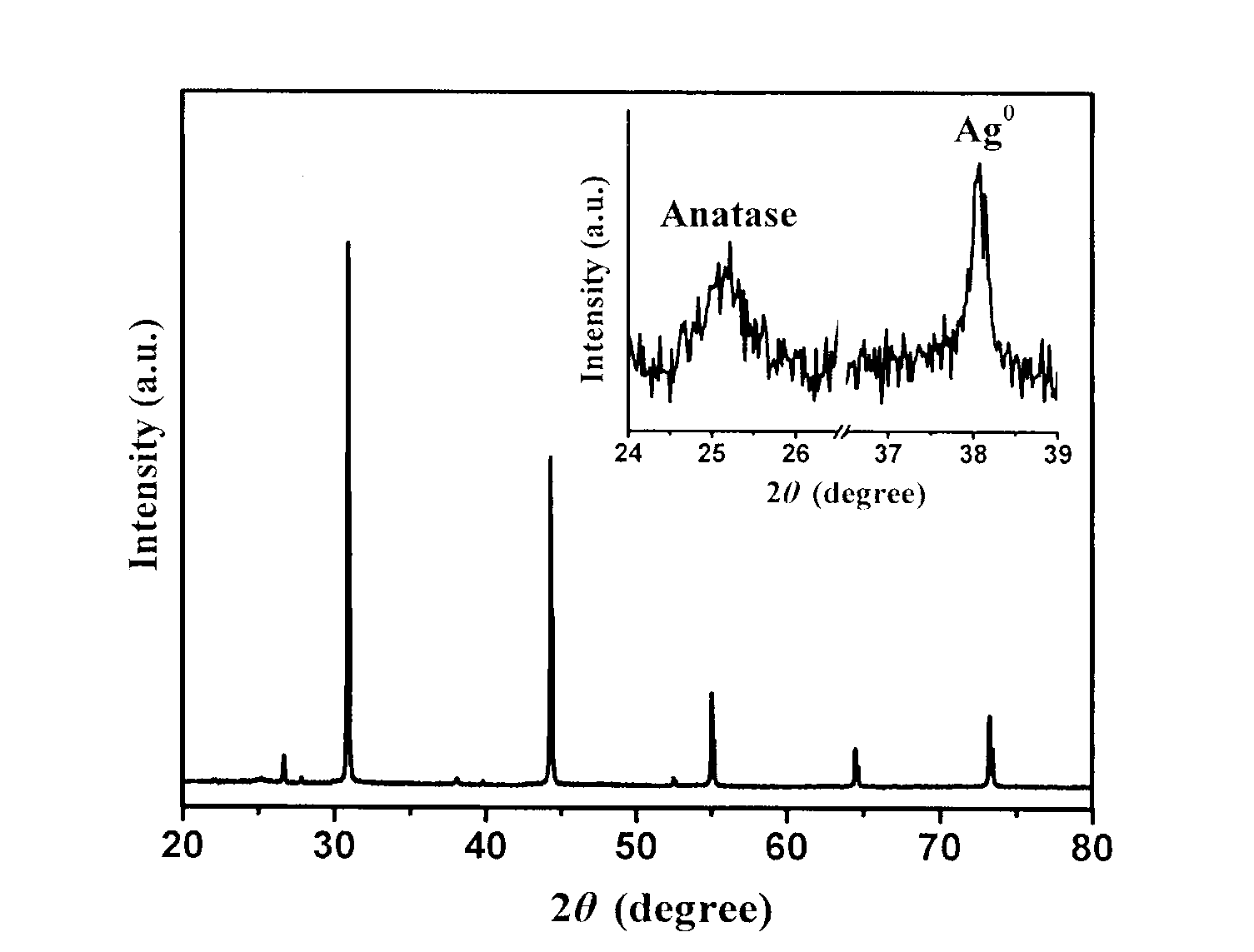

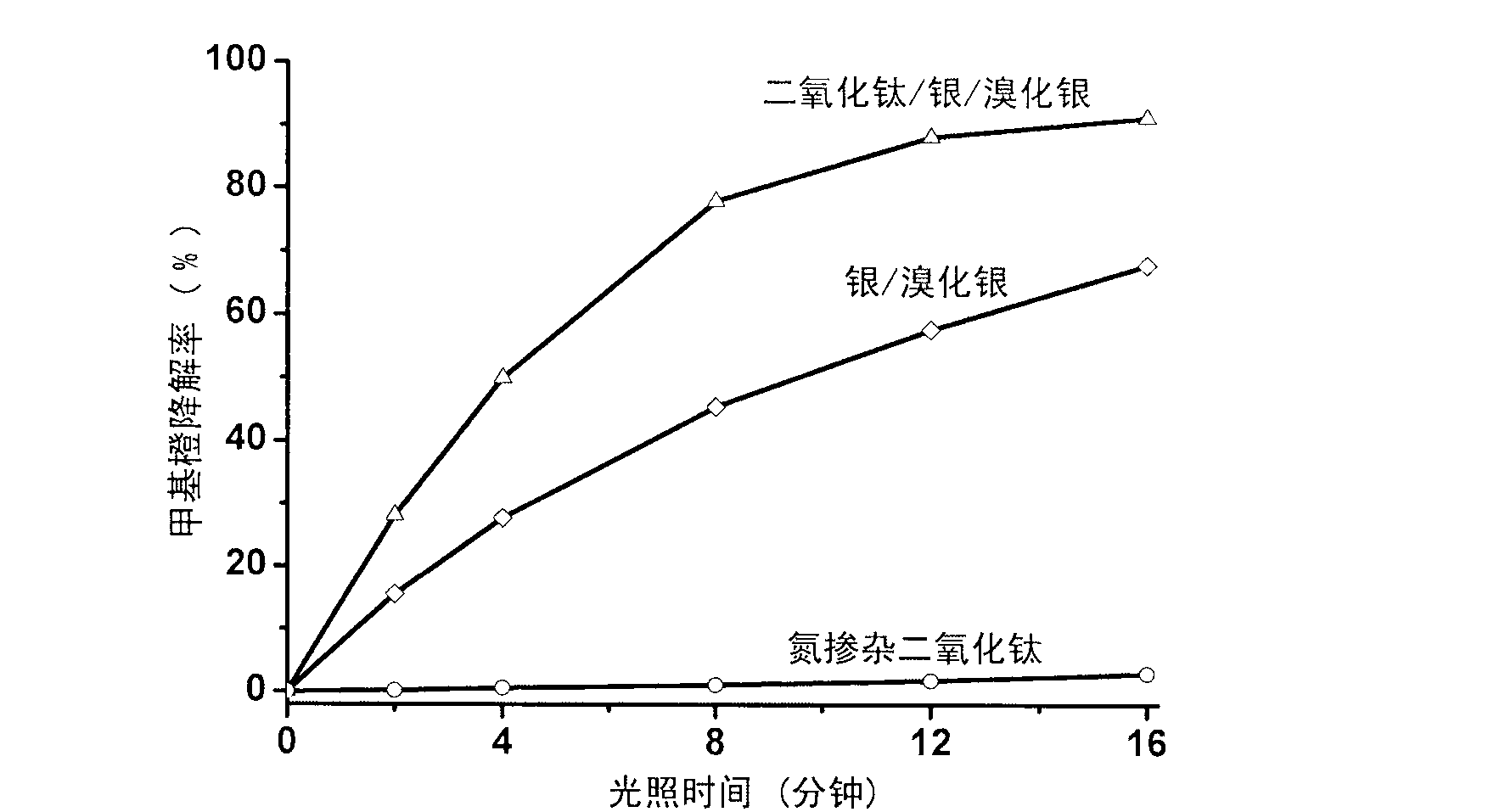

Embodiment 1

[0022] Under vigorous stirring, use a peristaltic pump to inject silver nitrate solution and potassium bromide solution into the reaction pot containing gelatin and potassium bromide aqueous solution at the same time, control the temperature of the reaction pot at 85 °C, and control the injection of silver nitrate and potassium bromide solution Speed, so that the pBr value of the whole reaction process is constant at 3.8. After the injection of the silver nitrate solution and the potassium bromide solution, physical maturation was carried out at this temperature for 30 minutes. Weigh a certain amount of silver bromide glue, add titanium sulfate (according to the thickness of the titanium dioxide coating layer is 0.06μm), gradually increase the temperature from 30°C to 80°C to promote the hydrolysis of titanium sulfate, and the hydrothermal temperature is 120°C. The prepared titanium dioxide / silver bromide composite semiconductor was centrifuged and washed 6 times with warm wat...

Embodiment 2

[0026] Under vigorous stirring, the silver nitrate solution and potassium bromide solution were simultaneously injected into the reaction pot containing polyvinylpyrrolidone K30 and potassium bromide aqueous solution with a peristaltic pump, and the temperature of the reaction pot was controlled at 85°C. The injection speed of the solution made the pBr value of the whole reaction process constant at 3.8. After the injection of the silver nitrate solution and the potassium bromide solution, physical maturation was carried out at this temperature for 30 minutes. Weigh a certain amount of silver bromide glue, add titanium sulfate (according to the thickness of the titanium dioxide coating layer is 0.06μm), gradually increase the temperature from 30°C to 80°C to promote the hydrolysis of titanium sulfate, and the hydrothermal temperature is 120°C. The prepared titanium dioxide / silver bromide composite semiconductor was centrifuged and washed 6 times with warm water at 45°C to remo...

Embodiment 3

[0028] Under vigorous stirring, use a peristaltic pump to inject silver nitrate solution and potassium bromide solution into the reaction pot containing gelatin and potassium bromide aqueous solution at the same time, control the temperature of the reaction pot at 60 °C, and control the injection of silver nitrate and potassium bromide solution Speed, so that the pBr value of the whole reaction process is constant at 3.8. After the injection of the silver nitrate solution and the potassium bromide solution, physical maturation was carried out at this temperature for 30 minutes. Weigh a certain amount of silver bromide glue, add titanium sulfate (according to the thickness of the titanium dioxide coating layer is 0.06μm), gradually increase the temperature from 30°C to 80°C to promote the hydrolysis of titanium sulfate, and the hydrothermal temperature is 120°C. The prepared titanium dioxide / silver bromide composite semiconductor was centrifuged and washed 6 times with warm wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com