Nickel titanium hydrotalcite and graphene composite photocatalyst responsive to visible lights and method for preparing same

A nickel-titanium hydrotalcite and graphene composite technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxygen preparation, etc., can solve the problem of timely and effective separation of photogenerated electron holes, limited photocatalytic activity, and adsorption performance drop and other issues, to achieve the effect of easy mass production, large surface area, and long recycling life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Under ice bath conditions, add 0.5g sodium nitrate to 23ml concentrated sulfuric acid, then add 0.5g graphite, stir well, add 3g potassium permanganate, mix well, then transfer to a water bath at 35°C for 2 hours, then put Adjust the temperature to 90°C for 30 minutes, add 100ml of deionized water and 3ml of 30wt% hydrogen peroxide to terminate the reaction, suction filter, wash, and dry to obtain graphite oxide;

[0019] 2. Put the graphite oxide into a muffle furnace at 1000°C and expand it for 5 minutes at high temperature, and the graphite oxide will be reduced to graphene;

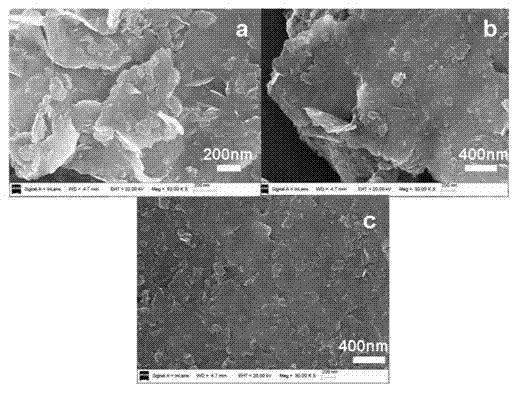

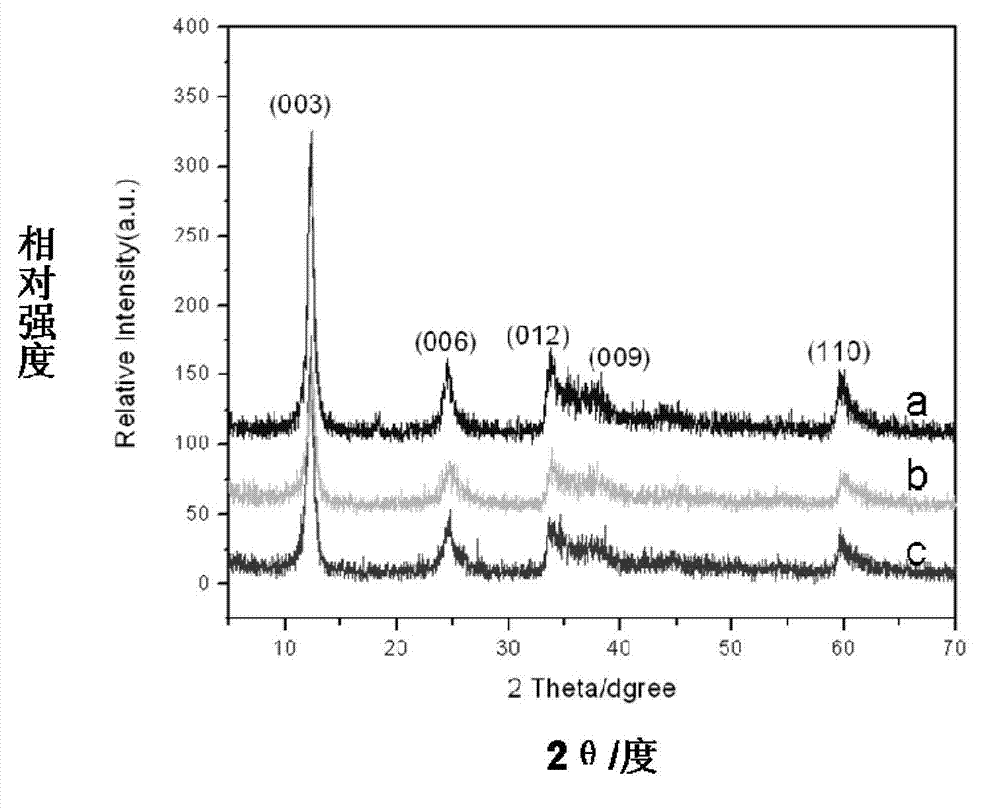

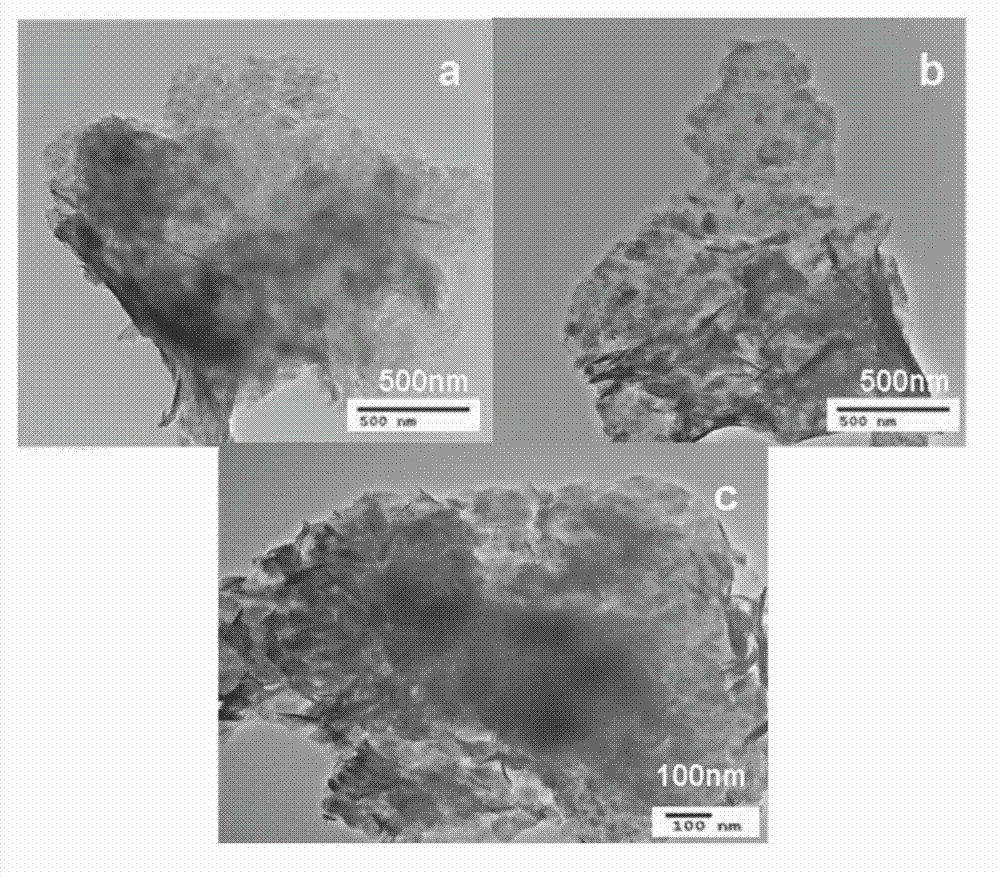

[0020] 3. Ultrasonic disperse 5mg graphene in 50ml deionized water, ultrasonic power 200W, ultrasonic time 30min; then add 2.32g nickel nitrate, adjust the pH of the system to 4 with concentrated hydrochloric acid, stir for 30min; then add 250μl TiCl 4 solution (which contains 0.0023mol TiCl 4 ), stir and dissolve; finally add 5.0g urea, and react in a hydrothermal constant temperature syst...

Embodiment 2

[0024] 1. With embodiment 1;

[0025] 2. With embodiment 1;

[0026] 3. Ultrasonic disperse 10mg graphene in 50ml deionized water, ultrasonic power 100W, ultrasonic time 40min; then add 2.9g nickel nitrate, adjust the pH of the system to 4.5 with concentrated hydrochloric acid, stir for 40min; then add 250μl TiCl 4 Solution (containing 0.0023mol TiCl 4 ), stir and dissolve; finally add 6.0g urea, and react in a hydrothermal constant temperature system at 92°C for 24h; the product is centrifugally washed with deionized water until it is neutral, and after drying, it is a composite of nickel-titanium hydrotalcite and graphene that responds to visible light catalyst of light.

[0027] The above-mentioned nickel-titanium hydrotalcite and graphene composite photocatalyst responsive to visible light, wherein the mass of graphene is 1% of the mass of nickel-titanium hydrotalcite; the chemical formula of the nickel-titanium hydrotalcite is: [Ni 2+ 1-x Ti 4+ x (OH) 2 ] x+ ·(CO ...

Embodiment 3

[0030] 1. With embodiment 1;

[0031] 2. With embodiment 1;

[0032] 3. Ultrasonic disperse 15mg graphene in 100ml deionized water, ultrasonic power 100W, ultrasonic time 60min; then add 3.49g nickel nitrate, adjust the pH of the system to 5 with concentrated hydrochloric acid, stir for 60min; then add 250μl TiCl 4 Solution (containing 0.0023mol TiCl 4 ), stir and dissolve; finally add 8.0g urea, and react in a hydrothermal constant temperature system at 98°C for 24h; the product is centrifugally washed with deionized water until it is neutral, and after drying, it is a composite of nickel-titanium hydrotalcite and graphene that responds to visible light catalyst of light.

[0033] The above-mentioned nickel-titanium hydrotalcite and graphene composite photocatalyst responsive to visible light, wherein the mass of graphene is 1.5% of the mass of nickel-titanium hydrotalcite; the chemical formula of the nickel-titanium hydrotalcite is: [Ni 2+ 1-x Ti 4+ x (OH) 2 ] x+ ·(C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com