Method for preparing organic fertilizer through tobacco extracting solution

A technology of tobacco extract and organic fertilizer, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of low resource utilization, unsatisfactory treatment effect, unbalanced discharge of extract, etc., and achieve improved physical and chemical properties and biological activity , increase and update soil organic matter, and promote the effect of microbial reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

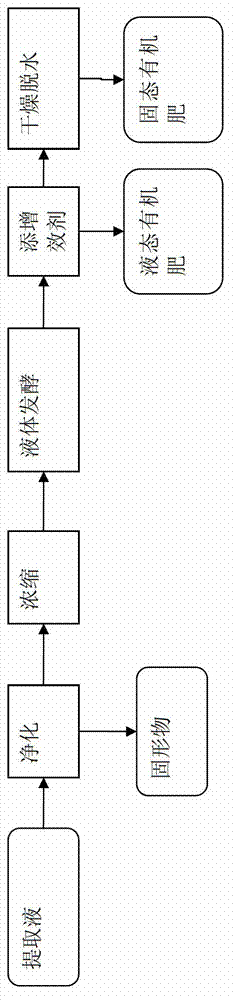

Method used

Image

Examples

Embodiment 1

[0033] Take 100kg of discarded flue-cured tobacco stems from Shanghai for this experiment.

[0034]Extraction: Put 100kg of tobacco stems into a stirring tank, inject 600kg (60°C) hot water into the tank, keep stirring for 2 hours, and then pump out 450kg of the extract.

[0035] Purification: Pump 450kg of the extract into a decanter centrifuge for sedimentation and centrifugation, and separate about 0.3kg of solid slag.

[0036] Concentration: pump 450kg of the purified extract into a negative pressure single-effect concentrator, and concentrate at a temperature of 60°C. After concentrating for 2 hours, 120 kg of tobacco stem liquid was produced, and the concentration of the detected stem liquid was 39%.

[0037] Fermentation: The concentrated stalk liquid is sterilized, then pumped into the biochemical reactor, and at the same time, 0.2kg of the prepared microbial agent is mixed into the stalk liquid. The pH value was adjusted to 6.5, the fermentation temperature was 50°C...

Embodiment 2

[0040] Take 150 kg of shredded stems of waste flue-cured tobacco from Shanghai for this test.

[0041] Extraction: Put 150kg of shredded stems into a mixing tank, pour 1500kg (70°C) hot water into the tank, heat and stir for 30 minutes, then squeeze dry with a single-screw juicer to obtain 1100kg of extract.

[0042] Purification: pump 1100kg of extract into a decanter centrifuge for sedimentation and purification, and separate 0.8kg of solid slag.

[0043] Concentration: pump 1100kg of purified extract into a negative pressure single-effect concentrator, and concentrate at a temperature of 60°C. After concentrating for 4 hours, 200 kg of tobacco stem liquid is produced, and the concentration of the detected stem liquid is 45%.

[0044] Fermentation: The concentrated stalk liquid is then pumped into the biochemical reactor, and at the same time, 2kg of the prepared microbial agent is mixed into the stalk liquid. The pH value was adjusted to 7, the fermentation temperature wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com