Xylo-oligosaccharide preparation method

A technology of xylooligosaccharides and raw materials, applied in the field of preparation of xylooligosaccharides, can solve problems such as high productivity, loss of consciousness, irritation of the skin and respiratory tract, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] direct enzymatic hydrolysis

[0040] The wheat bran is soaked in hot water above 70°C for 1-2 hours, then dehydrated, and then washed repeatedly with clean water at room temperature until the washing liquid is transparent and clear, so as to avoid the existence of other monosaccharides or colored substances. The washed wheat bran is dried at 45°C and then ground, then sieved through a 45-mesh sieve, and then added with water to prepare a 50% aqueous solution.

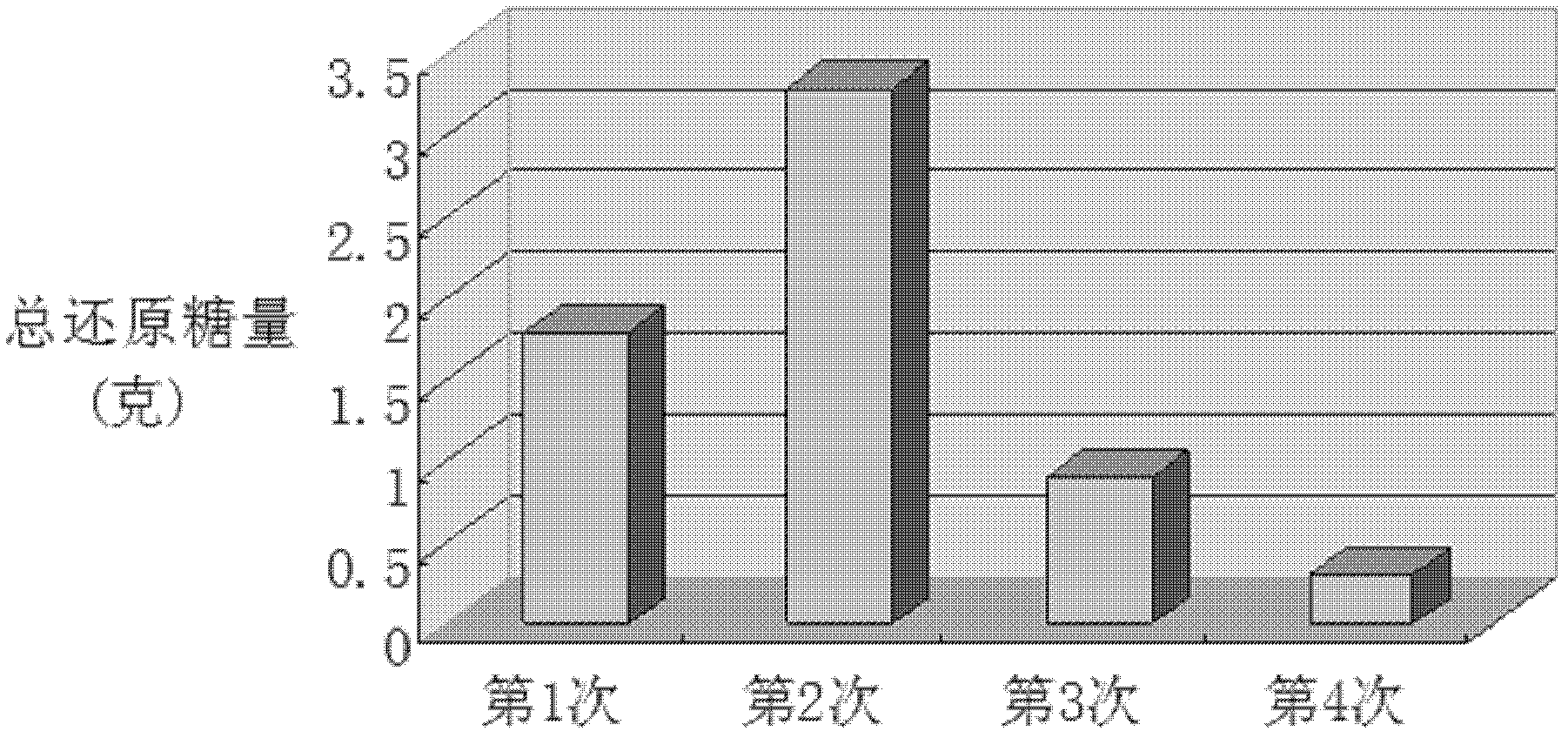

[0041] The above 50% aqueous solution was microwaved at 1400W for 2 minutes. After cooling, add water to prepare a 10% aqueous solution and add 0.5% (w / w) xylanase. The enzyme hydrolysis reaction was carried out at 55°C for 1 day. After the reaction, the aqueous solution was 100 mesh The filter screen was filtered and separated into filter residue and filtrate, wherein the filtrate was centrifuged at 3000g for 20 minutes, and part of the supernatant was taken out from the sediment to analyze reducing sugar by DNS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com