External heat radiation type dry distillation system for oil shale

A technology of oil shale and heat radiation, applied in the field of carbonization technology using external heat radiation type carbonization furnace, can solve the problems of complex process flow, low thermal efficiency, large gas volume, etc., and achieve simple process, large processing capacity and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

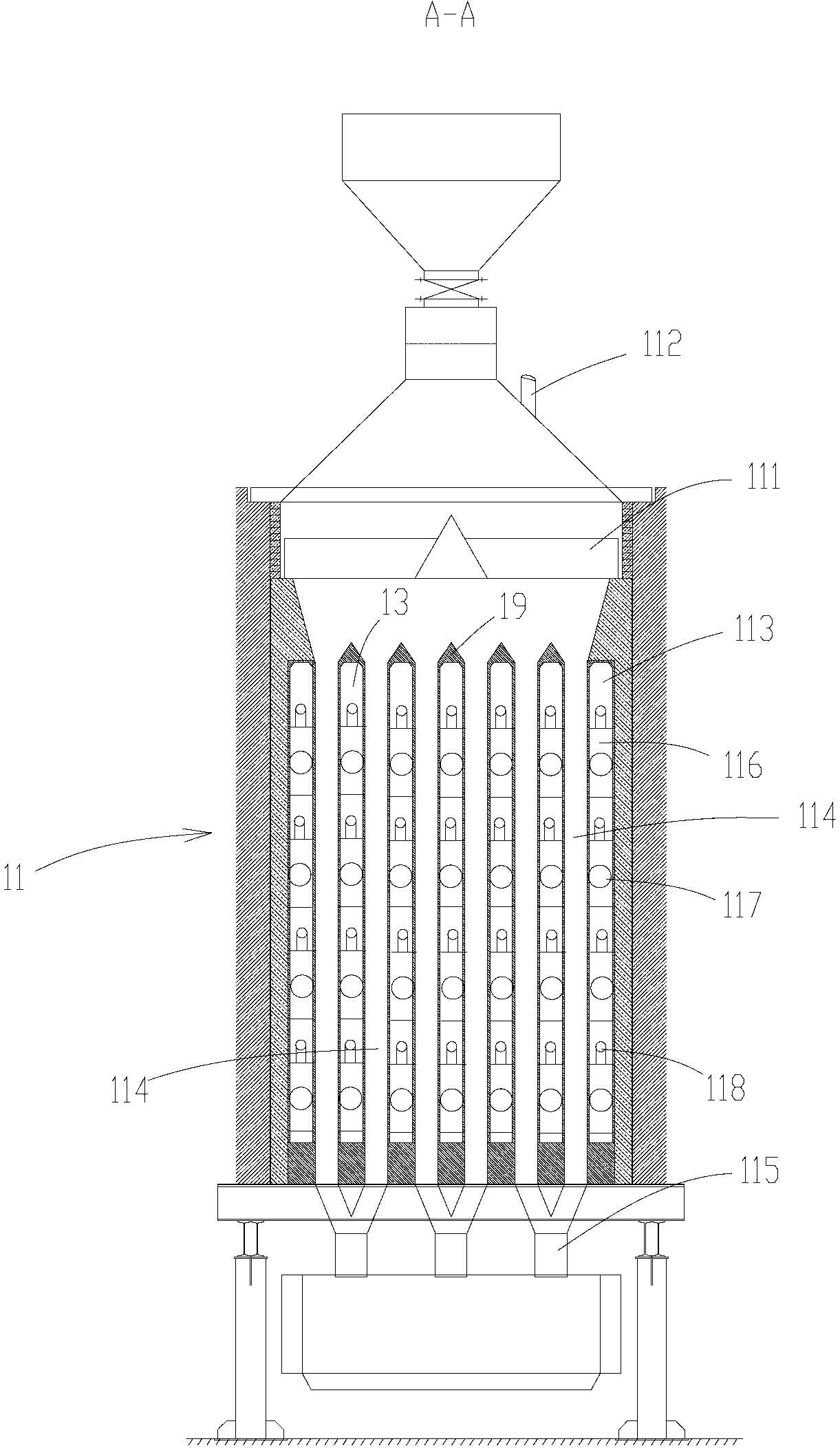

[0049] An oil shale external heat radiation retort system mainly includes: crushing and screening large pieces of oil shale into oil shale particles suitable for retort, preferably in the present invention, the oil shale is crushed and dried into 12-75mm particle size , and transport the oil shale particles to the feed system of the carbonization furnace.

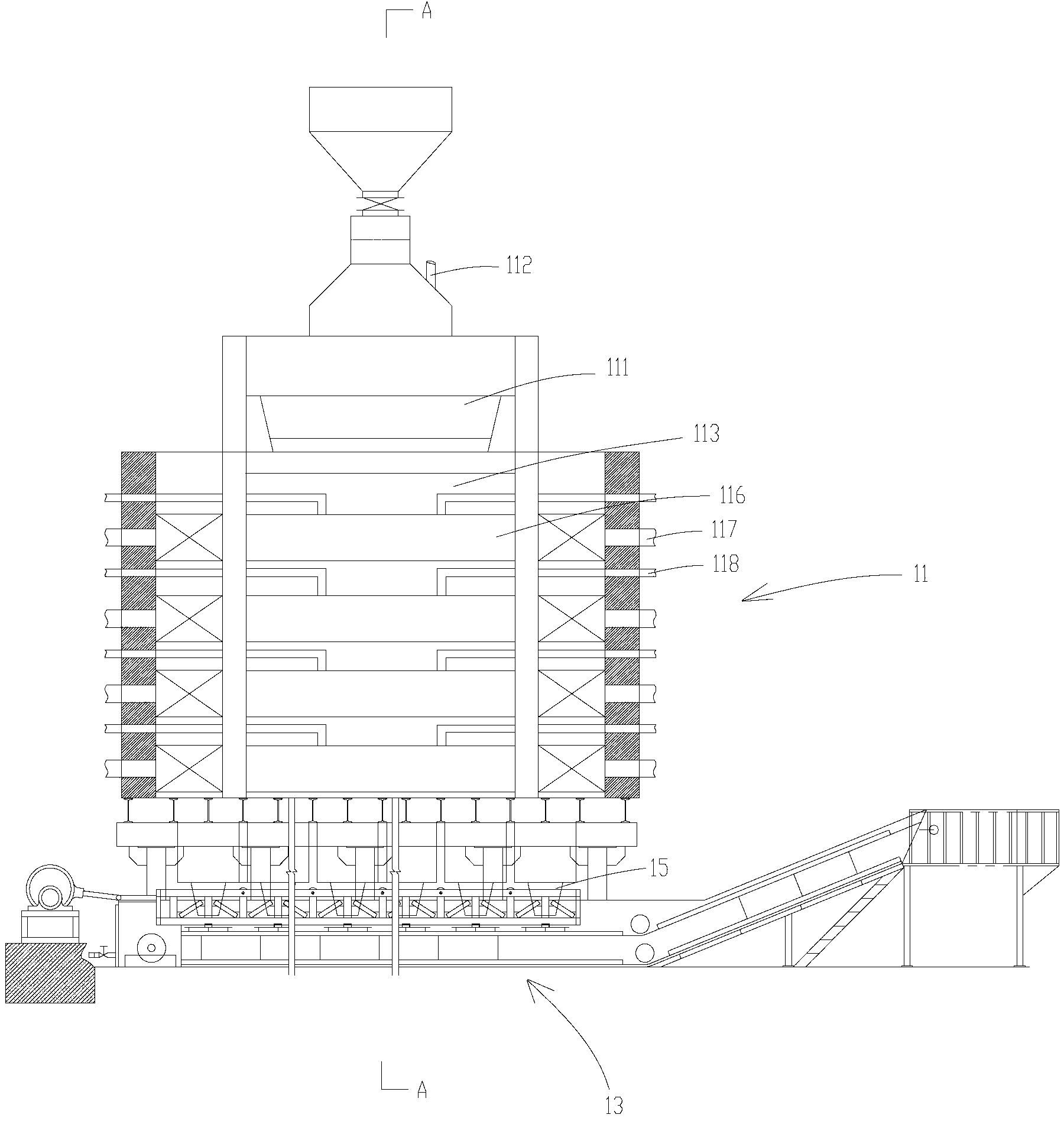

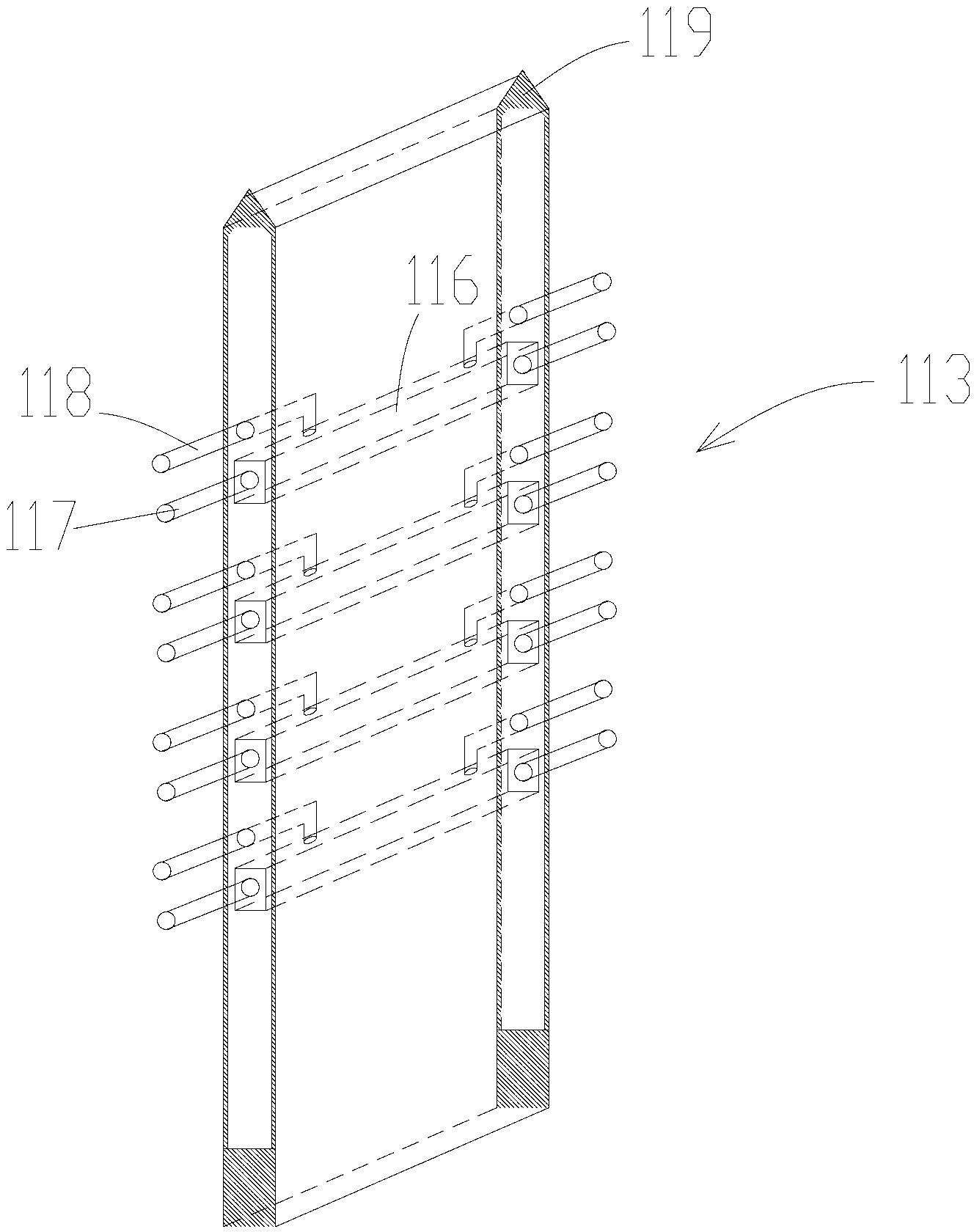

[0050] As the core of the whole carbonization system, it is a carbonization furnace that receives the oil shale particles delivered by the feed system and conducts carbonization on the particles.

[0051] Separation unit 2 for separating the mixed oil and gas produced by the carbonization furnace. The first oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com