Method for preparing biological fluidized bed carrier and treating waste water

A biological fluidized bed, wastewater treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high energy consumption, high cost and difficult post-treatment Recycling and other issues, to achieve the effect of good turbulent flow, easy sedimentation and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

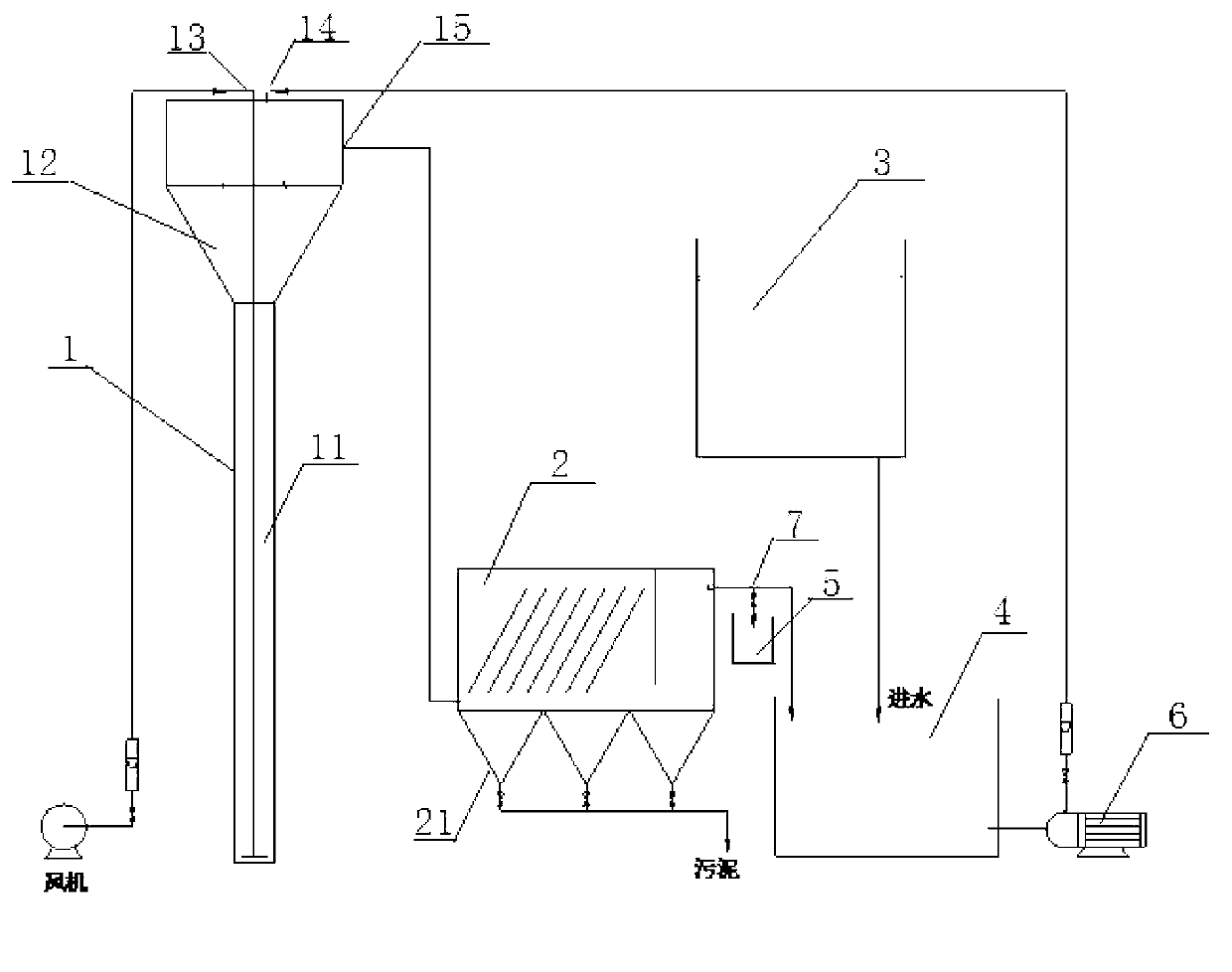

Image

Examples

Embodiment 1

[0025](1) Biological fluidized bed carrier: use a 8-30 mesh sieve to screen the coke powder from Shaanxi Shenmu Sanjiang Coal Chemical Co., Ltd. to screen out coke powder particles with a size of 0.6-2.5mm, about 10kg, and the screened particles Pour it into water, and screen the particles with a specific gravity higher than water (the specific gravity range is between 1.06-2.09) from it. After washing the impurities in the coke powder with water, dry it at 150°C to a constant weight, and put the dried carrier into the mass concentration of Immerse in 15% KOH aqueous solution for 6 hours, then wash several times with 5% HCl aqueous solution and dry at 150°C to obtain the biological fluidized bed carrier. The true density of the carrier is 1.6g / cm 3 , the pore size range is between 0-15nm, and the average pore size of BJH adsorption is 6.8653nm, ready for use, about 8kg.

[0026] (2) The method of using biological fluidized bed carrier to treat wastewater:

[0027] Described w...

Embodiment 2

[0031] The preparation of the biological fluidized bed carrier, the biological fluidized bed system, the culture medium, and the wastewater treatment method are the same as in Example 1.

[0032] Inoculate the activated sludge at the bottom of the main body of the biological fluidized bed. The inoculum volume of the activated sludge is 3 L. Add 10 kg of the biological fluidized bed carrier (the dosage is 45%). Turn on the air blower for 24 hours and then turn off the air blower. Set aside for 12 hours, discharge suspended sludge and sewage, continuously add culture medium at a rate of 2.5-5L / h from the waste water inlet, and discharge water from the waste water outlet. Add 2,4,6-trichlorophenol simulated wastewater with a COD concentration of 300mg / L and an ammonia nitrogen concentration of 5mg / L in the medium, aerated culture (3 weeks) until the thickness of the biofilm on the carrier is 45-70μm, stop adding For the culture medium, the above wastewater is used to replace the ...

Embodiment 3

[0034] The preparation of the biological fluidized bed carrier, the biological fluidized bed system, the culture medium, and the wastewater treatment method are the same as in Example 1.

[0035] Inoculate the activated sludge at the bottom of the main body of the biological fluidized bed. The inoculum volume of activated sludge is 3 L. Add 10 kg of biological fluidized bed carrier (dosing amount is 45%) about 9 kg. Turn on the blower and then close it after 24 hours of stuffy exposure Let the blower stand still for 12 hours, discharge the suspended sludge and sewage, continuously add the culture medium from the waste water inlet at a rate of 2.5-5L / h, and discharge the water from the waste water outlet. Add municipal sewage with a COD concentration of 836mg / L and an ammonia nitrogen concentration of 163mg / L to the culture medium, aerated culture (15 days) until the thickness of the biofilm on the carrier is 20-45μm, stop adding the culture medium, and replace it with the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com