Long chain paraffin hydrogenation heterogeneous condensation freezing point depressing method and catalyst thereof

A technology for hydrogenation of isomerized and long-chain alkanes, applied in the energy field, can solve the problems of limited use, not too obvious effect, low enough freezing point, etc., and achieves reduction of secondary reactions and cracking reactions, small crystal particles, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

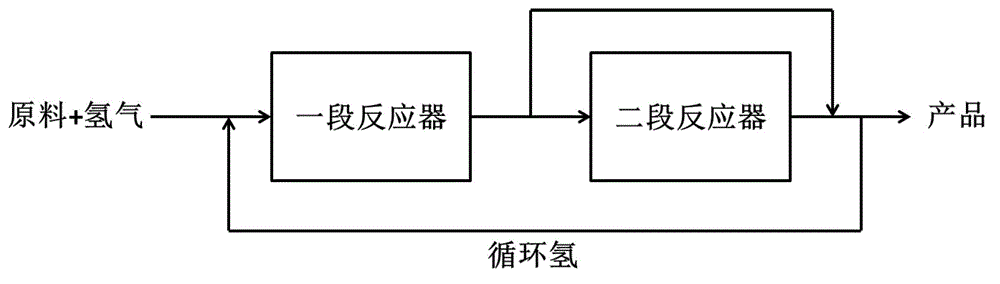

Method used

Image

Examples

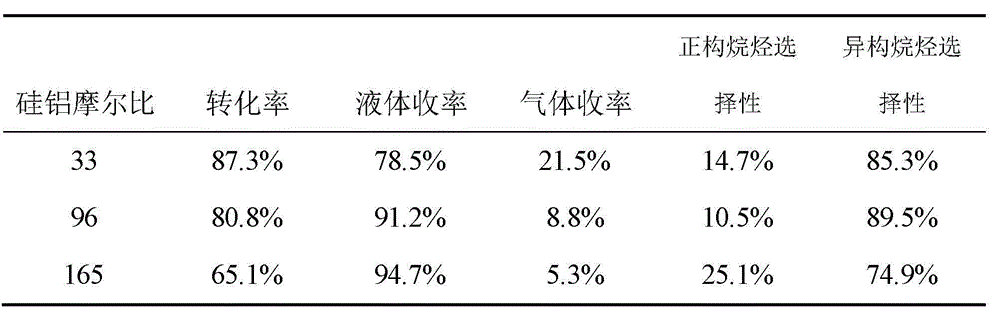

Embodiment 1

[0014] Preparation of different Pt / ZSM-48 catalysts. Three kinds of ZSM-48 molecular sieves with silicon-aluminum molar ratios of 33, 96, and 165 were ion-exchanged with 1mol / L ammonium nitrate aqueous solution, and repeated three times to keep the volume of ammonium nitrate aqueous solution and the mass ratio of molecular sieves at 20:1. After that, it is baked into a hydrogen ZSM-48 molecular sieve under the air atmosphere condition of 550°C to ensure that the weight content of sodium ions in the molecular sieve is less than 0.5%. The supported Pt catalyst was prepared by the equal volume impregnation method. The metal Pt precursor used was chloroplatinic acid, and the weight of metal Pt accounted for 0.4% of the total weight of the catalyst. After impregnation, three different Pt catalysts were obtained by drying, roasting and reduction. / ZSM-48.

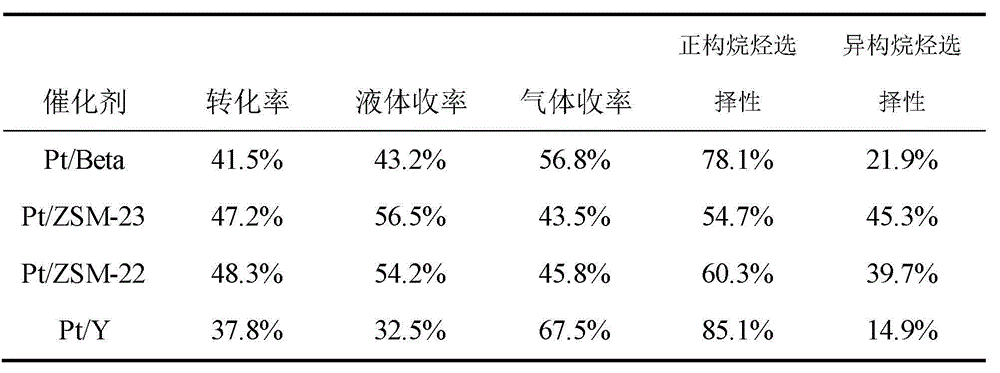

Embodiment 2

[0016] Preparation of Pt / Beta, Pt / ZSM-23, Pt / ZSM-22, Pt / Y catalysts. The silicon-aluminum molar ratios of the selected Beta, ZSM-23, ZSM-22, and Y molecular sieves are 32, 46, 87, and 12, respectively. The supported Pt catalyst was prepared according to the experimental procedure described in Example 1, the metal Pt precursor used was potassium chloroplatinate, and the weight of the metal Pt accounted for 0.4% of the total weight of the catalyst.

Embodiment 3

[0018] Preparation of Pt-Pd / ZSM-48 and Pt-Ru / ZSM-48 bimetallic catalysts. Two ZSM-48 molecular sieves with a silicon-aluminum molar ratio of 120 were ion-exchanged with 1.0mol / L ammonium nitrate aqueous solution, and repeated three times to keep the volume of ammonium nitrate aqueous solution and the mass ratio of molecular sieves at 20:1. Calcined into hydrogen type ZSM-48 molecular sieve under the condition of air atmosphere at 550°C to ensure that the weight content of sodium ions in the molecular sieve is less than 0.5%. Adopt equal volume impregnation method to prepare supported bimetallic catalyst, impregnate metal Pd or Ru earlier, the metal Pd precursor that adopts is palladium nitrate, the metal Ru precursor is ruthenium trichloride, and the weight of metal Pd or Ru accounts for 10% of the total catalyst weight 0.2%, drying and roasting after impregnation, and then impregnating metal Pt, the metal Pt precursor used is chloroplatinic acid, and the weight of metal Pt ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com