A kind of environment-friendly acetylene hydrochlorination catalyst and preparation method thereof

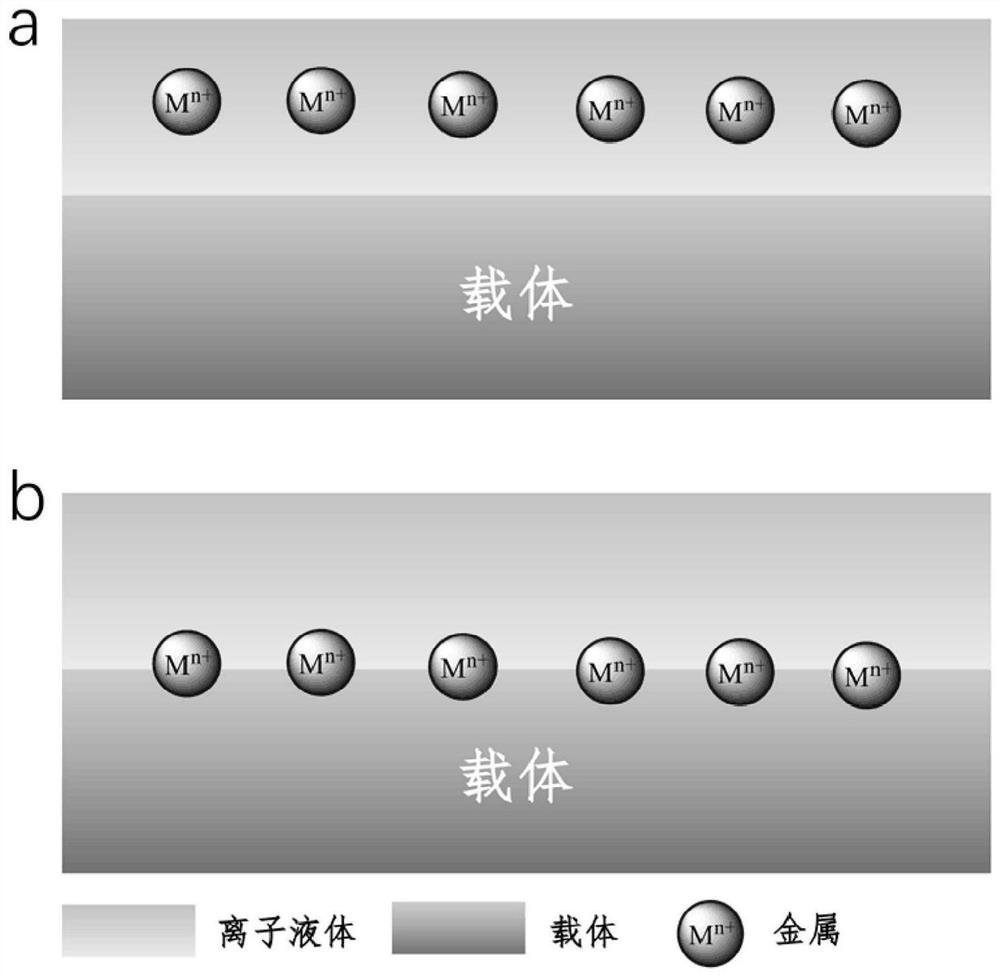

A kind of acetylene hydrochlorination, environment-friendly technology, applied in catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve low mass transfer, gas metal dispersion No high problems, achieve high catalytic activity, high stability, and reduce the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

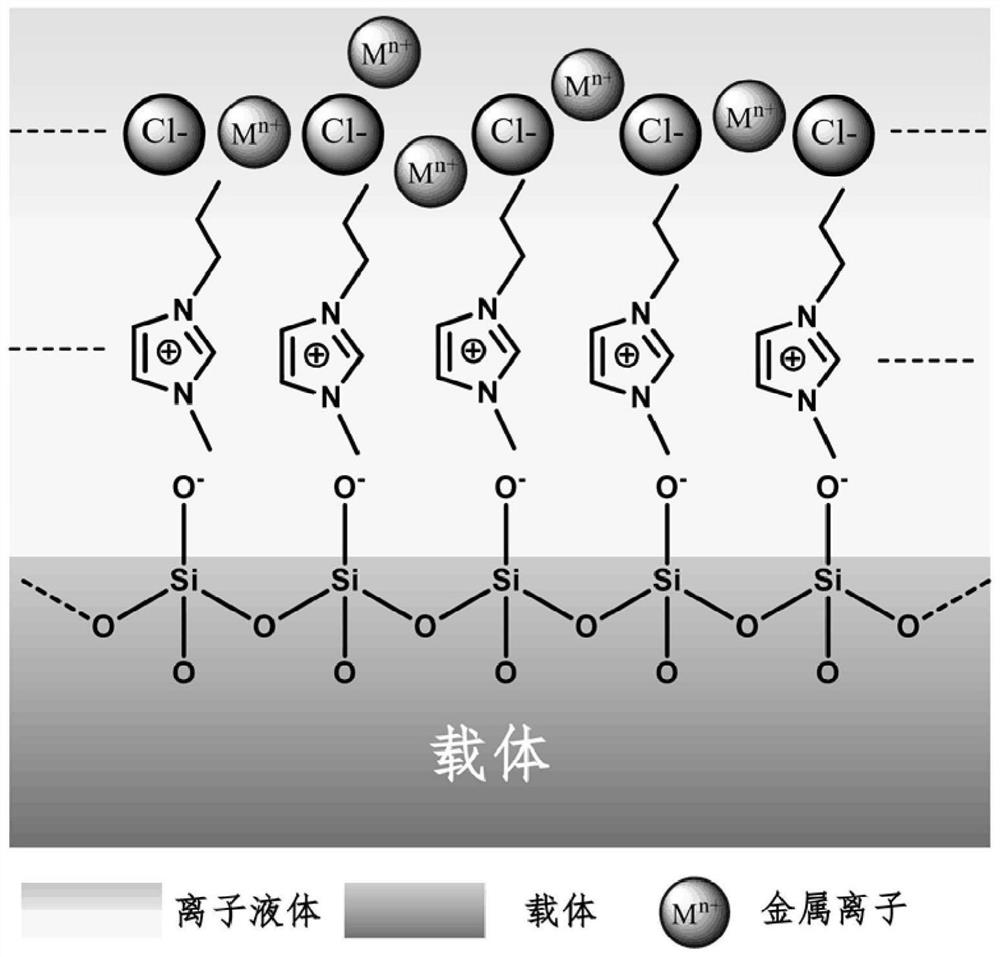

Method used

Image

Examples

Embodiment 1

[0076] Preparation of catalyst:

[0077] 1) Select 10 g of zirconium nitride as the carrier, dissolve it in 40 mL of nitrogen nitrogen dimethylformamide, stir for 30 min, and add 0.1 g of dimethyldichlorosilane and 1.0 g of triethylamine. The above mixture was heat treated under nitrogen at 50°C for 5 hours. After filtering, the filter cake was washed with nitrosodimethylformamide and ethanol, dried at 180°C, and the obtained solid sample was used for later use.

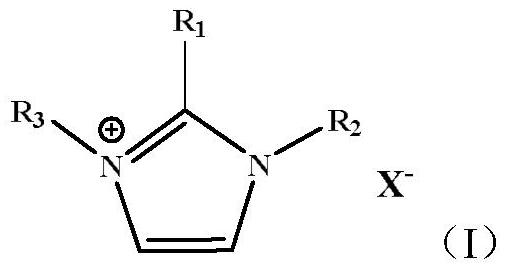

[0078] 2) Dissolve 0.04g of 1-octyl-3-methylimidazolium hexafluorophosphate and 0.06g of 1-propyl-3-butylimidazolium tetrafluoroborate ionic liquid in 10mL of nitrogen-nitrogen dimethylformamide , after stirring evenly, the solid sample obtained in step 1) was added, immersed for 10 h, and dried at 180° C. for use. The mass loading of the ionic liquid is 1%.

[0079] 3) Dissolve 0.009g of chloroauric acid and 0.13g of sodium chloride in 0.09mL of nitrogen-nitrogen dimethylformamide, stir evenly, add the sample obt...

Embodiment 2

[0084] Preparation of catalyst:

[0085] 1) Select 10 g of silicon nitride as the carrier, dissolve it in 100 mL of toluene, stir for 30 min, and add 0.1 g of dimethyldichlorosilane and 0.2 g of triethylamine. The above mixture was heat treated under nitrogen at 80°C for 3 hours. After filtering, the filter cake was washed with toluene and ethanol, dried at 180°C, and the obtained solid sample was used for later use.

[0086] 2) Dissolve 0.4 g of 1-hexyl-3-ylimidazolium hexafluorophosphate and 1.6 g of nitrogen methylpyrrolidone hydrochloride ionic liquid in 10 mL of toluene, stir evenly, add the solid sample obtained in step 1), immerse 2h, and dried at 180°C for later use. The mass loading of the ionic liquid is 20%.

[0087] 3) Dissolve 4.23g cupric chloride and 0.03g barium chloride in 2.12mL toluene, stir evenly, add the sample obtained in step 2), immerse it in an external 0.6kV static electric field for 2.5h, and heat it at 180°C Dry under conditions for later use. ...

Embodiment 3

[0092] Preparation of catalyst:

[0093] 1) Select 10 g of titanium nitride as the carrier, dissolve it in 200 mL of nitrogen methyl pyrrolidone, stir for 30 min, and add 0.6 g of dimethyldichlorosilane and 1.0 g of triethylamine. The above mixture was heat treated under nitrogen at 70°C for 4 hours. After filtering, the filter cake was washed with nitrogen methyl pyrrolidone and ethanol, dried at 180°C, and the obtained solid sample was used for later use.

[0094]2) Dissolve 1.0 g of 1-ethyl-2,3-dimethylimidazolium tetrafluorophosphate and 0.5 g of triphenylmethylphosphonium bromide ionic liquid in 30 mL of nitrogen methylpyrrolidone, stir evenly, and add step 1 ), immersed for 8 h, and dried at 180 °C for later use. The mass loading of the ionic liquid is 15%.

[0095] 3) Mix 0.103 g of ruthenium chloride and 0.73 g of ferric chloride and dissolve in 0.5 mL of nitrogen methyl pyrrolidone, stir evenly, add the sample obtained in step 2), immerse it in an external 0.8 kV s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com