Method for treating PX (para-xylene) wastewater by using active carbon as adsorbent

A technology of activated carbon and adsorbent, which is applied in the field of PX wastewater treatment, can solve the problems affecting the living environment of people and organisms, and achieve the effect of wide source of adsorbent, low treatment cost and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

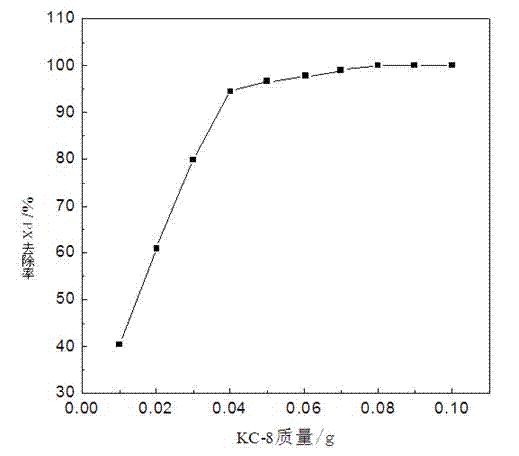

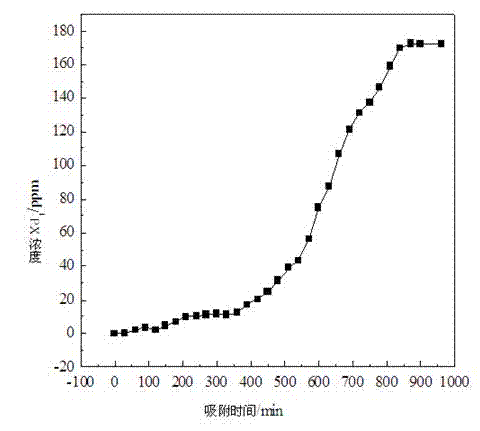

Embodiment 1

[0027] Take 57 g of PX aqueous solution with a concentration of 170 ppm, and add 0.04 g of 30-mesh KC-8 activated carbon into the intermittent adsorption vessel filled with wastewater. The adsorption temperature is controlled at 40 °C, and the vibration speed of the adsorber is 100 rpm. The p-xylene concentration in the aqueous solution was measured in real time, and its variation with time was investigated. When the concentration of p-xylene in the aqueous solution no longer changes, it can be considered that the activated carbon has been adsorbed and saturated. At this time, the adsorption capacity of activated carbon was 235 mg / g, the residual PX concentration in water was 13 ppm, and the removal rate of PX in water reached 92.3%.

Embodiment 2

[0029] In order to compare the adsorption effect, the experiments of Example 1 were carried out using KC-6 activated carbon and coal-based activated carbon respectively, and other conditions were unchanged. When KC-6 activated carbon is used, the adsorption capacity of activated carbon is 234 mg / g, the residual PX concentration in water is 16 ppm, and the removal rate of PX in water reaches 90.8%; when coal-based activated carbon is used, the adsorption capacity of activated carbon is 204 mg / g, and the water The residual PX concentration was 32 ppm, and the removal rate of PX in water was 81.2%.

Embodiment 3

[0031] Take 57 g of PX aqueous solution with a concentration of 130 ppm, add 0.04 g of 40-mesh KC-8 activated carbon into the intermittent adsorption vessel containing wastewater, control the adsorption temperature to 40 °C, and the vibration speed of the adsorber to 200 rpm. At adsorption equilibrium, the adsorption capacity of activated carbon was 180 mg / g, the residual PX concentration in water was 3 ppm, and the removal rate of PX in water reached 97.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com