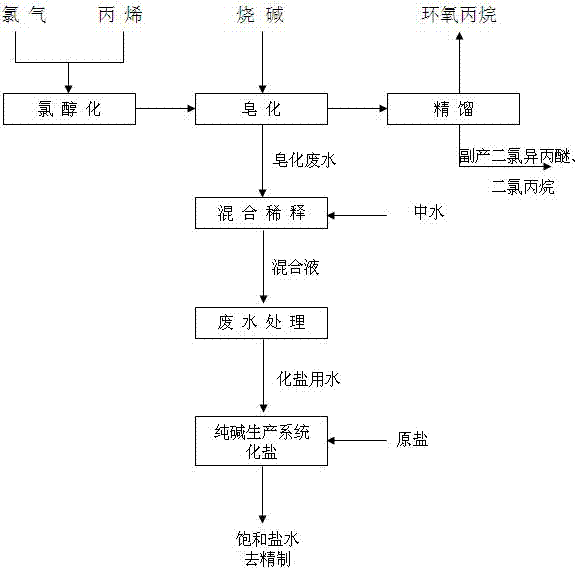

Process for producing epoxypropane by adopting caustic soda saponification method

A technology for producing propylene oxide and a production process, which is applied in the field of producing propylene oxide with caustic soda as a saponification agent, can solve problems such as pollution, and achieve the effects of zero emission and reduced refining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Dissolve chlorine gas in process water preheated to 35°C to generate a hypochlorous acid solution, then pass excess propylene into the hypochlorous acid solution for chloroalcoholization reaction, the molar ratio of chlorine gas to propylene is 1:1.05, and generate chlorine-containing Propanol is a solution of 3.5wt% and equimolar hydrochloric acid, the reaction pressure is normal pressure, and the reaction temperature is 55°C;

[0019] (2) Mix the solution containing 3.5wt% chloropropanol and 11wt% caustic soda solution according to the molar ratio of sodium hydroxide / chloropropanol+hydrochloric acid at 1.1:1, saponification reaction occurs in the saponification tower, and quickly stripped to obtain The crude propylene oxide of 90wt%, saponification reaction temperature is controlled at 90 ℃, and saponification tower top pressure is 35Kpa absolute pressure;

[0020] (3) Send the crude propylene oxide with a content of 90wt% into the propylene oxide front distillati...

Embodiment 2

[0023] (1) Dissolve chlorine gas in process water preheated to 40°C to generate a hypochlorous acid solution, then pass excess propylene into the hypochlorous acid solution for chloroalcoholization reaction, the molar ratio of chlorine gas to propylene is 1:1.1, and generate chlorine-containing Propanol is 3.7wt% chloropropanol solution, the reaction pressure is slightly higher than normal pressure, and the reaction temperature is 68°C;

[0024] (2) Mix chloropropanol solution containing 3.7wt% chloropropanol with 12wt% caustic soda solution according to the sodium hydroxide / chloropropanol+hydrochloric acid molar ratio of 1.15: 1, saponification reaction occurs in the saponification tower, and rapidly The crude propylene oxide of 95wt% is obtained by stripping, the saponification reaction temperature is controlled at 100°C, and the pressure at the top of the saponification tower is 40Kpa absolute pressure;

[0025] (3) Send the crude propylene oxide with a content of 95wt% int...

Embodiment 3

[0028] (1) Dissolve chlorine gas in process water preheated to 45°C to generate a hypochlorous acid solution, then pass excess propylene into the hypochlorous acid solution for chloroalcoholization reaction, the molar ratio of chlorine gas to propylene is 1:1.1, and generate chlorine-containing Propanol is 4wt% chloropropanol solution, the reaction pressure is normal pressure, and the reaction temperature is 65°C;

[0029] (2) The molar ratio of chloropropanol solution containing 4wt% chloropropanol to 13wt% caustic soda solution sodium hydroxide / chloropropanol+hydrochloric acid is 1.2:1, saponification reaction occurs in the saponification tower, and quickly stripped to obtain The crude propylene oxide of 95wt%, saponification reaction temperature is controlled at 100 ℃, and saponification tower top pressure is 40Kpa absolute pressure;

[0030](3) Send the crude propylene oxide with a content of 95wt% into the propylene oxide front distillation tower and rectification tower. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com