Method for simultaneously determining W, B and Nb in high-alloy deposited metal

A technology for surfacing metals and alloys, which is used in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc. It can solve the problems of large amount of reagents, narrow detection range, long operation process, etc. The effect of less reagent consumption and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment: Taking the selected surfacing metal sample as an example, the technical solution involved in the invention is described in detail.

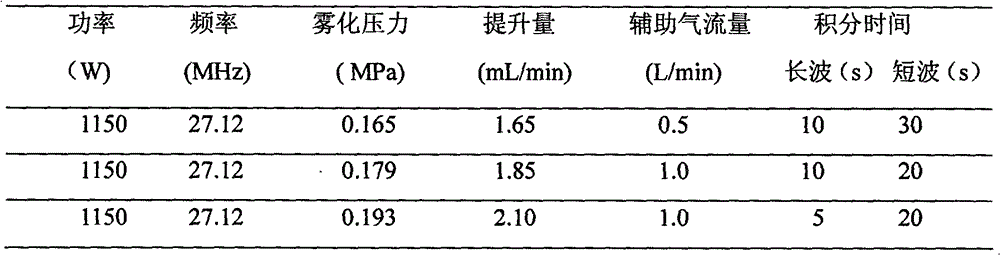

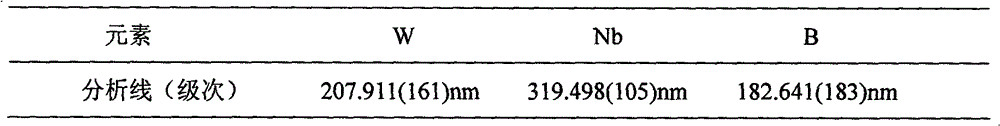

[0023] 1. Instruments and equipment used in the present invention: IRIS Advantage ER / S full-spectrum direct-reading plasma emission spectrometer; Speedwave MSW3+ microwave digestion instrument

[0024] 2. Main reagents

[0025] Hydrochloric acid (excellent pure, ρ about 1.19g / mL); nitric acid (excellent pure, ρ about 1.42g / mL); hydrofluoric acid (excellent pure, ρ about 1.15g / mL)

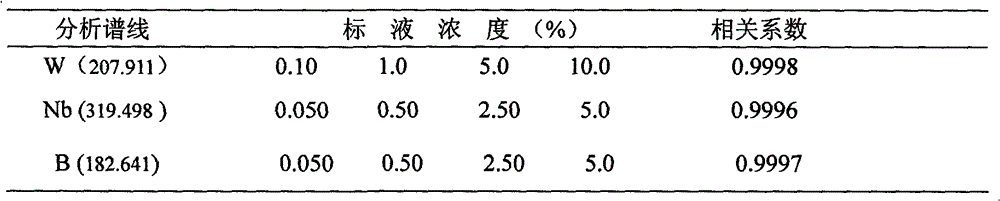

[0026]Tungsten, boron, niobium standard stock solution: 1mg / mL, all prepared according to the national standard method.

[0027] 3. Sample treatment: Weigh 0.1000g sample and place it in a polytetrafluoroethylene microwave digestion tank. After washing the cup wall with about 3mL deionized water, first add 3mL hydrochloric acid. After the sample reacts, add 2mL nitric acid, 2mL Hydrofluoric acid, mix well, install the explosion-proof film, and cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com