Environmental hazardous material monitoring and early warning system and its preparation method

A technology of early warning system and dangerous objects, applied in the direction of manufacturing tools, welding equipment, optical mechanical equipment, etc., can solve problems such as no substantive breakthroughs, achieve the effects of convenient system, overcoming complex components, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

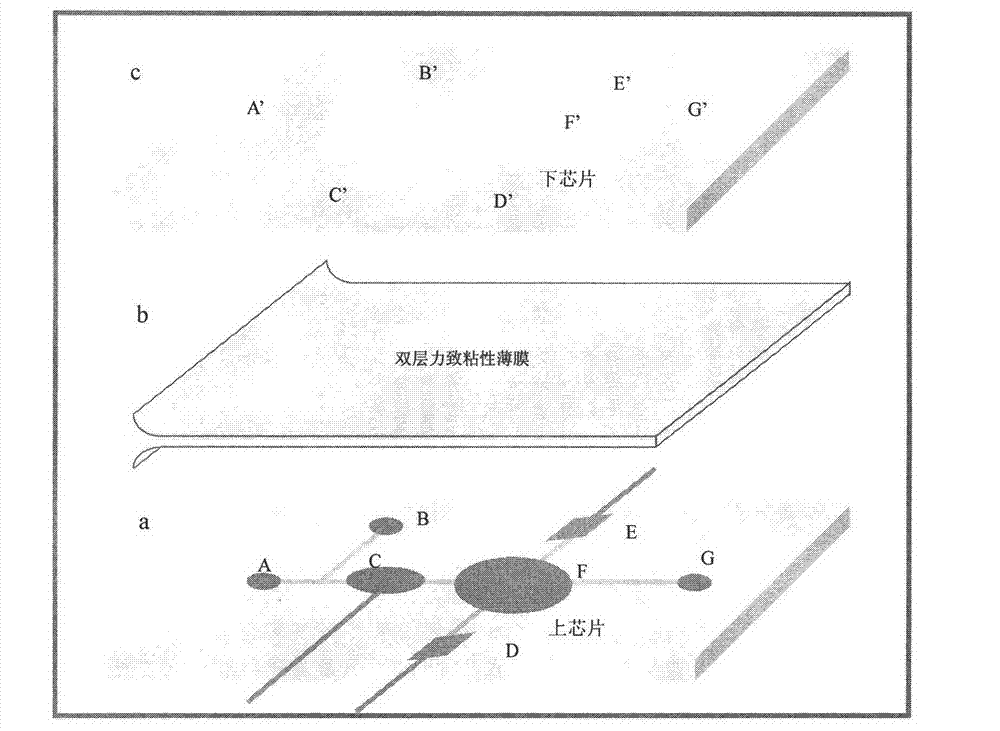

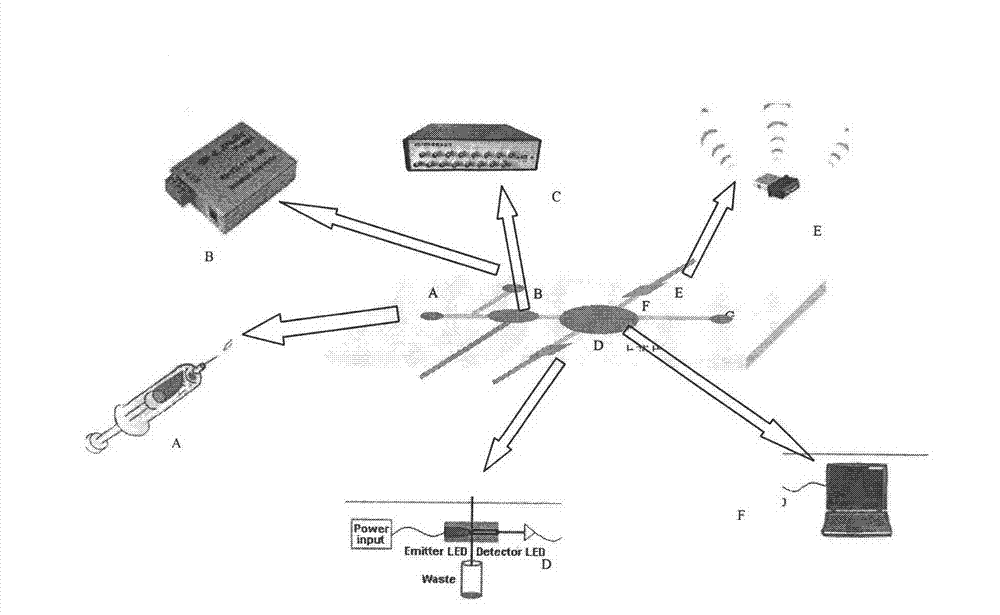

[0031] Use computer-aided design (CAD) to draw the design graphics of the microfluidic chip, and then use photolithography-chemical etching to etch the required microchannel network on the surface of the upper and lower glass (5×5cm). Clean the glass with detergent, ethanol, deionized water, acetone, and ethanol, and dry it at room temperature. Integrate functional devices such as high-throughput data acquisition, information processing and transmission, automatic analysis and monitoring, and network remote control on a small microfluidic chip. Connect the auxiliary equipment of functional devices such as high-throughput data acquisition, information processing and transmission, automatic analysis and monitoring, and network remote control with the above-mentioned functional devices. The upper and lower layers of chips are sealed to form a chip micro-full analysis system. Connect the micro-fluid delivery micro-pump, the analysis and detection workstation and the microcomputer...

Embodiment 2

[0033] Use computer-aided design (CAD) to draw the design graphics of the microfluidic chip, and then use the laser printer to print the graphics as a photomask, and then use an excimer laser etching machine on the surface of an organic polymer substrate (such as polymethyl methacrylate). ) to prepare the required chip microchannel network. After cutting the organic polymer base material, washing with ethanol, deionized water and ethanol, and drying naturally, two organic polymer chips (5×5 cm) were obtained. Integrate functional devices such as high-throughput data acquisition, information processing and transmission, automatic analysis and monitoring, and network remote control on a small microfluidic chip. Connect the auxiliary equipment of functional devices such as high-throughput data acquisition, information processing and transmission, automatic analysis and monitoring, and network remote control with the above-mentioned functional devices. The upper and lower layers of...

Embodiment 3

[0035] Use computer-aided design (CAD) to draw the design graphics of the microfluidic chip, and use the numerical control CNC micromachining system to mill and process the required microchannel network graphics on the surface of the organic polymer substrate (polycarbonate). The organic polymer substrate was cleaned with detergent, deionized water, ethanol, deionized water, and ethanol, and then dried naturally to obtain two organic polymer chips (5×5 cm). Integrate functional devices such as high-throughput data acquisition, information processing and transmission, automatic analysis and monitoring, and network remote control on a small microfluidic chip. Connect the auxiliary equipment of functional devices such as high-throughput data acquisition, information processing and transmission, automatic analysis and monitoring, and network remote control with the above-mentioned functional devices. The upper and lower layers of chips are sealed to form a chip micro-full analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com