Manganese dioxide/ferric oxide nanometer composite material as well as preparation method and application thereof

An iron oxide nanometer and composite material technology is applied in the field of inorganic nanocomposite material preparation, which can solve the problems of low conductivity of manganese dioxide, and achieve the effects of controllable morphology, good cycle stability and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

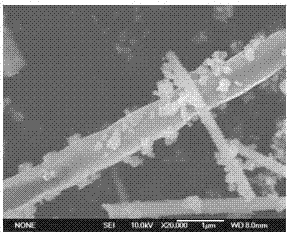

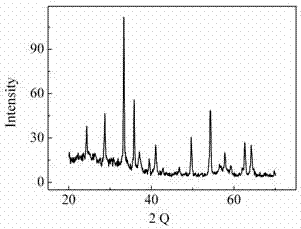

[0025] (1) Add potassium ferrocyanide to 0.002 mol / L potassium permanganate solution to obtain a transparent mixed solution with a molar ratio of iron:manganese of 3:1.

[0026] (2) The mixed solution prepared in step (1) was introduced into a hydrothermal reaction kettle, and a hydrothermal reaction was carried out at 120° C. for 24 hours to obtain a suspension.

[0027] (3) The suspension obtained in step (2) is filtered, the filter cake is washed with distilled water, and then dried at 60°C to obtain a manganese dioxide / iron oxide nanocomposite material.

[0028] (4) The composite material prepared in the preparation step (3) was mixed with conductive carbon and polytetrafluoroethylene at a mass ratio of 75:20:5 to form a composite material electrode. In the three-electrode system, the specific capacitance of the prepared composite electrode in 1 mol / L sodium sulfate solution reached 530 F / g, and the specific capacity remained at 92% after 2000 charge-discharge cycles.

Embodiment 2

[0029] (1) Add potassium ferrocyanide to 0.002 mol / L potassium permanganate solution to prepare a transparent mixed solution with a molar ratio of iron: manganese of 3:1.

[0030] (2) The mixed solution prepared in step (1) was introduced into a hydrothermal reaction kettle, and a hydrothermal reaction was carried out at 120° C. for 48 hours to obtain a suspension.

[0031] (3) The suspension obtained in step (2) is filtered, the filter cake is washed with distilled water, and then dried at 60°C to obtain a manganese dioxide / iron oxide nanocomposite material.

[0032] (4) Mix and press the composite material prepared in step (3) with conductive carbon and polyvinylidene fluoride at a mass ratio of 75:20:5 to prepare a composite material electrode. In the three-electrode system, the specific capacitance of the prepared composite electrode in 1 mol / L sodium sulfate solution reached 462 F / g, and the specific capacity remained at 87% after 2000 charge-discharge cycles.

Embodiment 3

[0033] (1) Add potassium ferrocyanide to 0.01 mol / L potassium permanganate solution to prepare a transparent mixed solution with a molar ratio of iron:manganese of 3:1.

[0034] (2) The mixed solution prepared in step (1) was introduced into a hydrothermal reaction kettle, and a hydrothermal reaction was carried out at 150° C. for 48 hours to obtain a suspension.

[0035] (3) The suspension obtained in step (2) is filtered, the filter cake is washed with distilled water, and then dried at 60°C to obtain a manganese dioxide / iron oxide nanocomposite material.

[0036] (4) Mix the composite material prepared in step (3) with conductive carbon and styrene-butadiene rubber at a mass ratio of 75:20:5 and press into tablets to prepare a composite material electrode. In the three-electrode system, the specific capacitance of the prepared composite electrode in 1 mol / L sodium sulfate solution reached 380 F / g, and the specific capacity remained at 86% after 2000 charge-discharge cycles....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com