Method for producing environment-friendly biological feed employing distiller grains and glycoprotein

A bio-feed and environment-friendly technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, animal feed, etc., can solve the problems of limited utilization ratio, low resource utilization rate, short life, etc., and achieve the inhibition of Escherichia coli and Salmonella, Highly active yeast cell count, the effect of promoting rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

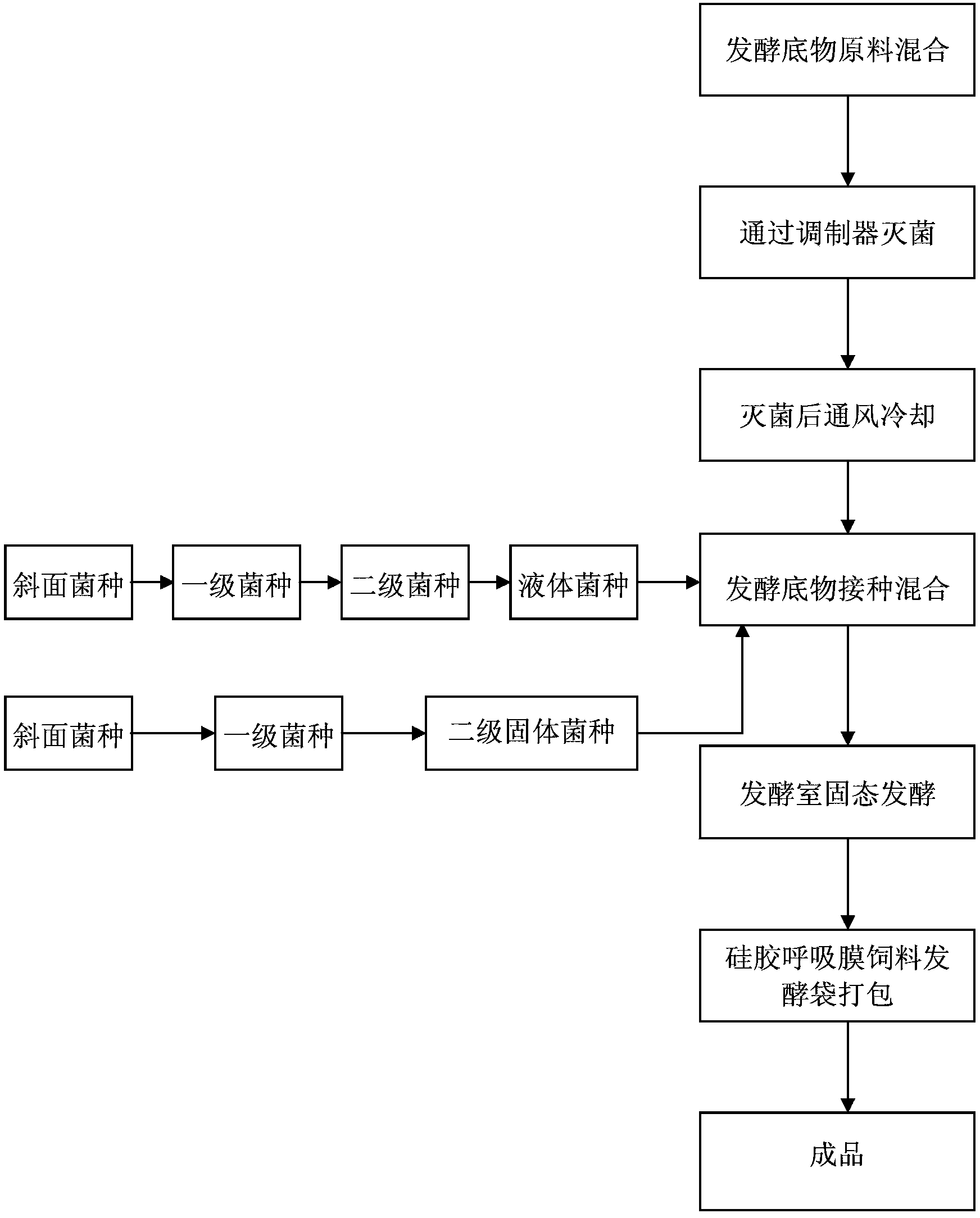

[0057] see figure 1 , prepare the environment-friendly biological feed of the present embodiment according to the following method:

[0058] 1. Accurately weigh 80kg of rice bran, 450kg of distiller's grains, 300kg of corn glycoprotein, 50kg of corn spray fiber, 50kg of corn flour, 50kg of bran, and 20kg of molasses, and mix them evenly to make a fermentation substrate. The moisture content of the fermentation substrate is 45% .

[0059] 2. The fermentation substrate is subjected to 0.3 MPa saturated steam through a conditioner, and is sterilized by instant cooking at 140° C. for 1 min.

[0060] 3. After the fermentation substrate is sterilized, enter the wet material mixer, stir continuously and pass in cold air, so that the temperature of the fermentation substrate drops to about 32°C.

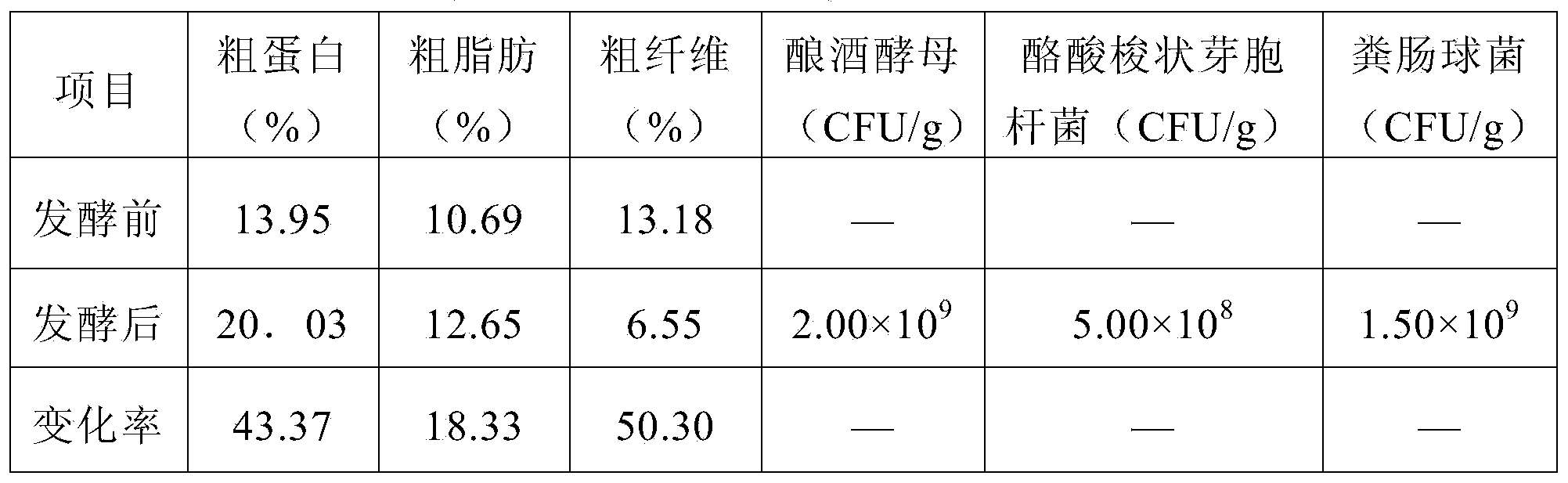

[0061] 4. Inoculate Trichoderma koningeni, Clostridium butyricum, Saccharomyces cerevisiae and Enterococcus faecalis at 5%, 5%, 10% and 10% of the weight of the fermentation substrate resp...

Embodiment 2

[0097] see figure 1 , prepare the environment-friendly biological feed of the present embodiment according to the following method:

[0098] 1. Accurately weigh 100kg of rice bran, 500kg of distiller's grains, 100kg of corn glycoprotein, 70kg of corn spray fiber, 100kg of corn flour, 100kg of bran, and 30kg of molasses, and mix them evenly to make a fermentation substrate. The moisture content of the fermentation substrate is 45% .

[0099] 2. The fermentation substrate is subjected to 0.3 MPa saturated steam through a conditioner, and is sterilized by instant cooking at 140° C. for 1 min.

[0100] 3. After the fermentation substrate is sterilized, enter the wet material mixer, stir continuously and pass in cold air, so that the temperature of the fermentation substrate drops to about 32°C.

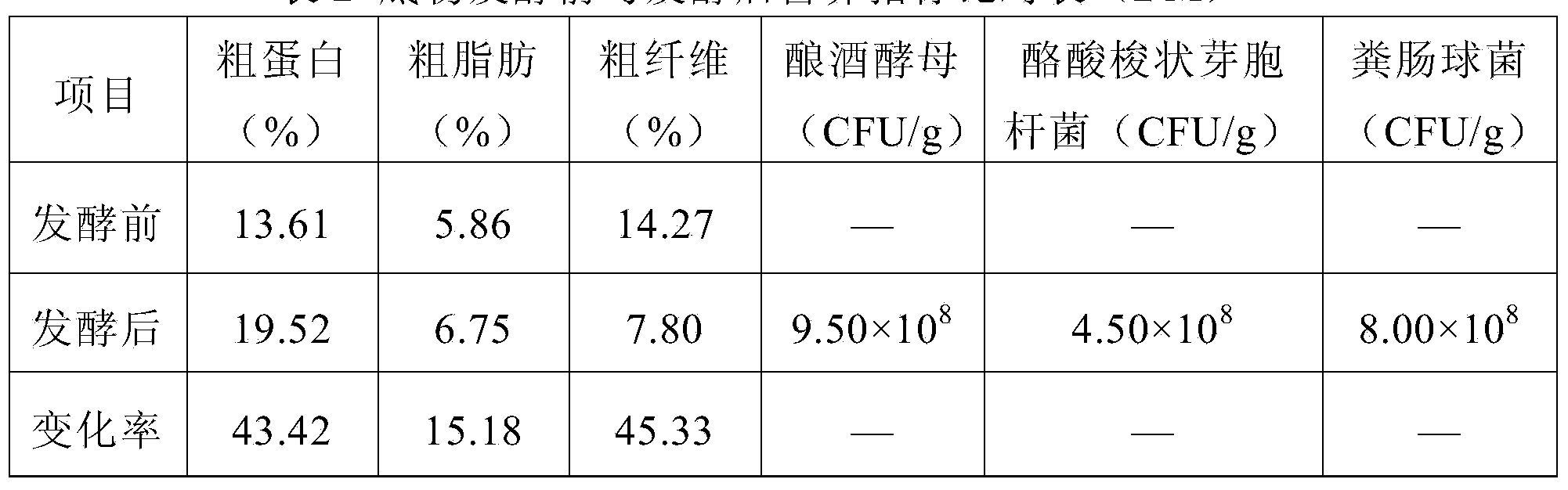

[0101] 4. Inoculate Trichoderma koningeni, Clostridium butyricum, Saccharomyces cerevisiae and Enterococcus faecalis at 5%, 5%, 5% and 5% of the weight of the fermentation substrate, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com