Preparation method of conductive polymer polypyrrole modified TiO2 and application thereof

A neutral and reactive technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water pollutants, etc., can solve problems such as high energy band gap and low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Prepare 80 mL of hydrochloric acid solution with pH=1, and weigh 1.73g of TiOSO 4 Add it to 80 mL of hydrochloric acid at PH=1, and put it in a water bath at 5°C and stir it dynamically until the solution is clear. Add 3.5 mL of pyrrole dropwise to the above solution, and then slowly add 3.9 mL of hydrogen peroxide to the mixed solution. (The mass concentration is 30%). Continue to stir at a constant temperature for 6 hours. After the reaction, the precipitate is repeatedly washed with deionized water and absolute ethanol until the solution is neutral. Finally, the sample is placed in a vacuum oven at 60°C. Drying in middle temperature for 12h, the PPy-TiO 2 composite photocatalyst.

[0023] (2) The PPy-TiO prepared in the above step (1) 2 The photocatalytic degradation test of the composite photocatalyst was carried out in a photochemical reaction apparatus, and the degradation rate of salicylic acid by the photocatalyst was 48.57%.

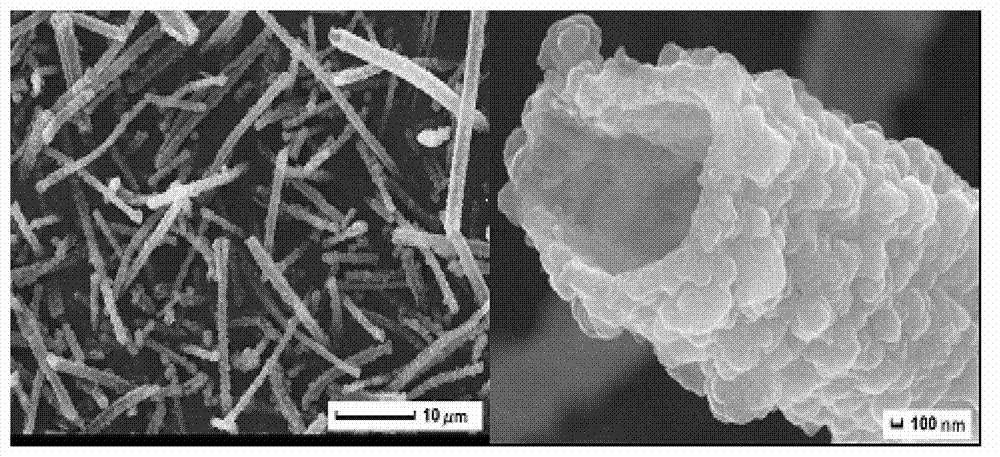

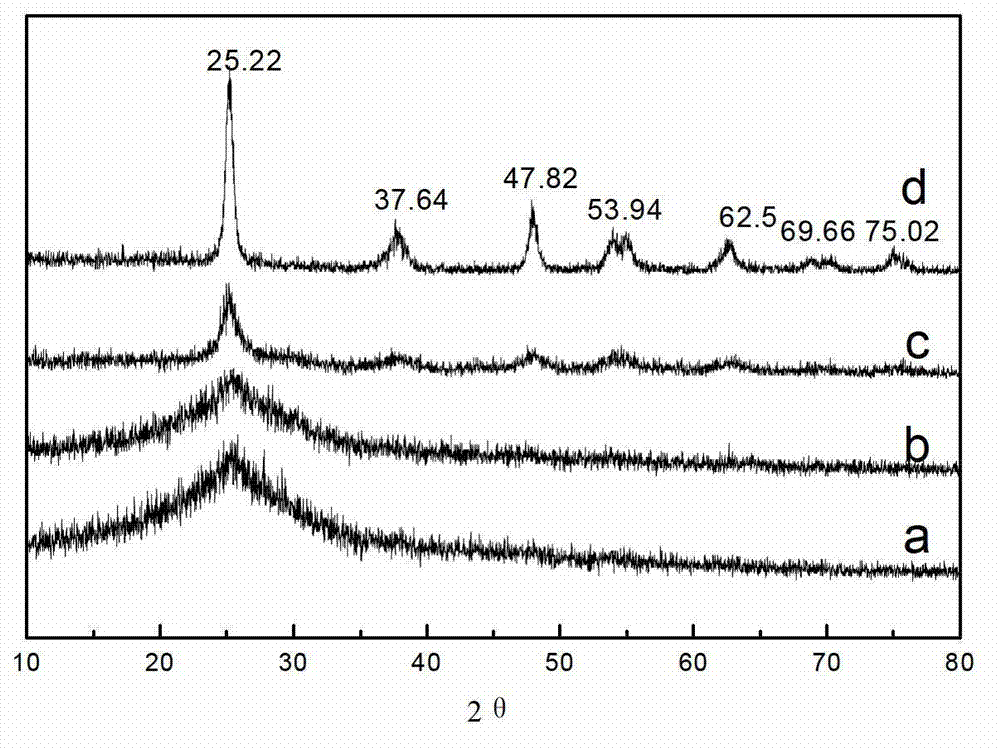

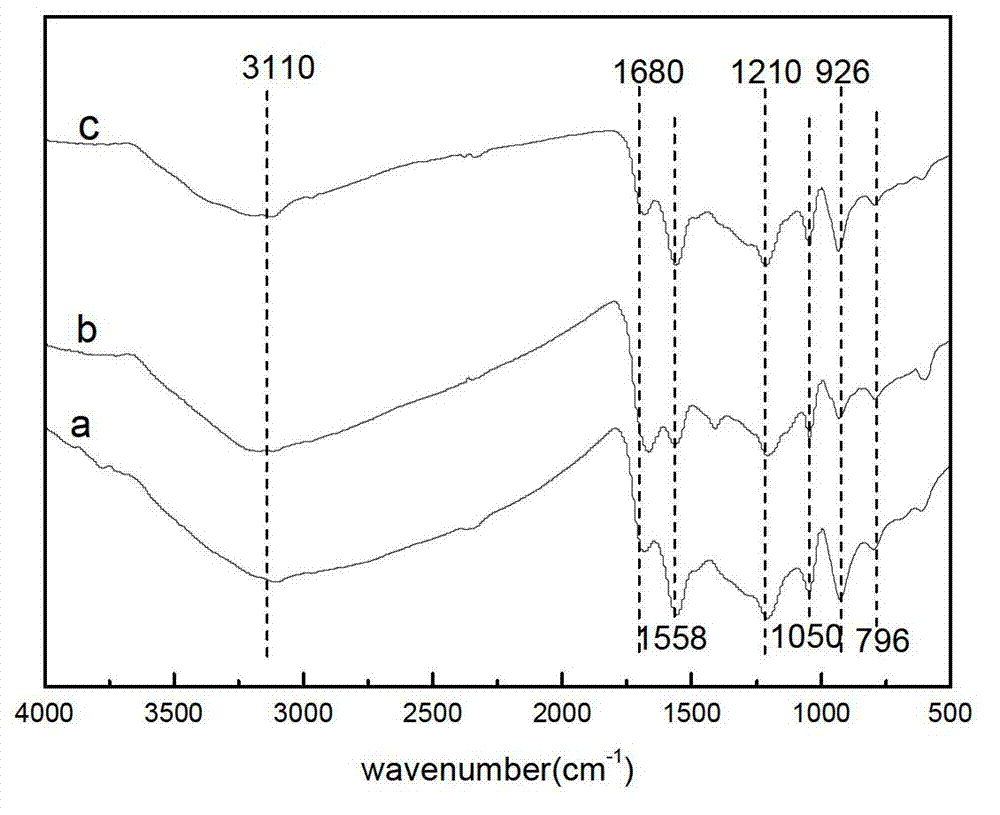

[0024] figure 1 It is the ...

Embodiment 2

[0027] (1) Prepare 80 mL of hydrochloric acid solution with pH=2, and weigh 1.73g of TiOSO 4 Add it to 80 mL of hydrochloric acid at PH=2, put it in a water bath at 5°C and stir it until the solution is clear, add 3.5 mL of pyrrole dropwise to the above solution, and then slowly add 3.9 mL of hydrogen peroxide to the mixed solution (mass concentration is 30%), continue dynamic stirring at a constant temperature for 6 hours, after the reaction, the precipitate is washed repeatedly with deionized water and absolute ethanol for several times until the solution is neutral, and finally the sample is placed in a vacuum oven at 60°C Drying in middle temperature for 12h, the PPy-TiO 2 composite photocatalyst.

[0028] (2) The PPy-TiO prepared in the above step (1) 2 The photocatalytic degradation test of the composite photocatalyst was carried out in a photochemical reaction apparatus, and the degradation rate of salicylic acid by the photocatalyst was 40.57%.

Embodiment 3

[0030] (1) Prepare 80 mL of hydrochloric acid solution with pH=3, and weigh 1.73g of TiOSO 4 Add it to 80 mL of hydrochloric acid at PH=3, and put it in a water bath at 5°C to stir until the solution is clear. Add 3.5 mL of pyrrole dropwise to the above solution, and then slowly add 3.9 mL of hydrogen peroxide to the mixed solution. (mass concentration is 30%), continue dynamic stirring at a constant temperature for 6 hours, after the reaction, the precipitate is washed repeatedly with deionized water and absolute ethanol for several times until the solution is neutral, and finally the sample is placed in a vacuum oven at 60°C Drying in middle temperature for 12h, the PPy-TiO 2 composite photocatalyst.

[0031] (2) The PPy-TiO prepared in the above step (1) 2 The photocatalytic degradation test of the composite photocatalyst was carried out in a photochemical reaction apparatus, and the degradation rate of salicylic acid by the photocatalyst was 36.57%. Therefore, the compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com