Preparation method of porous graphene oxide

A graphene and porous technology, which is applied in the field of preparation of porous graphene oxide, can solve the problems of low storage density, high impedance, and difficulty in large-scale application, and achieves good reproducibility, mild reaction, size and thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

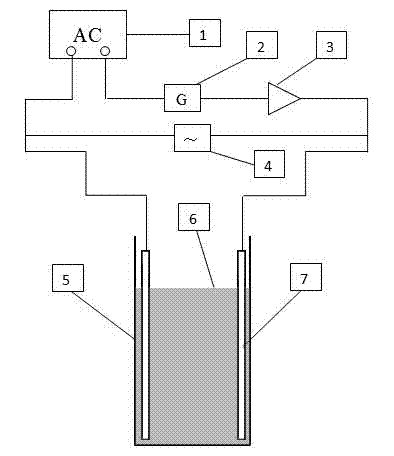

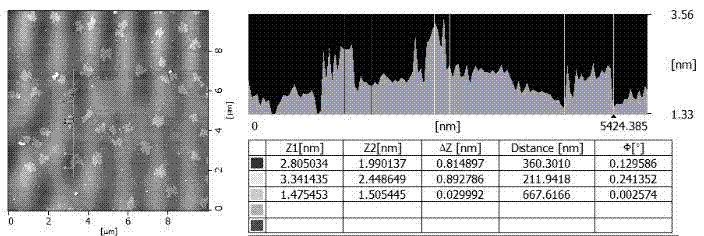

[0032] Embodiment 1: graphite oxide suspension 0.5mg / ml, stripping voltage is 40V, stripping frequency is 40Hz, stripping time is 120min

[0033] Using 30um natural flake graphite as raw material, graphite oxide was prepared by Hummers method; the obtained graphite oxide was dissolved in deionized water. At room temperature, use a magnetic stirrer to disperse for 30 minutes, prepare a 0.5 mg / ml GO suspension, and then transfer it to a cuboid electrolytic cell, and place graphite electrodes on both sides of the electrolytic cell; one end of the AV signal line is connected to the signal generator Connect the output port of the power amplifier to the output port of the power amplifier, and connect the other end to the input port of the power amplifier; connect the test probes of the oscilloscope to the positive and negative connectors of the output signal line of the power amplifier; the positive and negative connectors are respectively connected to the graphite electrodes. Turn ...

Embodiment 2

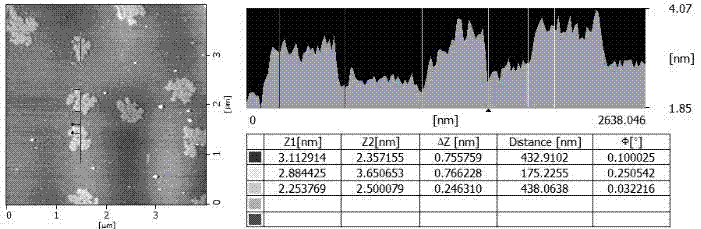

[0035] Embodiment 2: graphite oxide suspension 0.5mg / ml, stripping voltage is 60V, stripping frequency is 40Hz, stripping time is 120min

[0036]Using 30um natural flake graphite as raw material, graphite oxide was prepared by Hummers method; the obtained graphite oxide was dissolved in deionized water. At room temperature, use a magnetic stirrer to disperse for 30 minutes, prepare a 0.5 mg / ml GO suspension, and then transfer it to a cuboid electrolytic cell, and place graphite electrodes on both sides of the electrolytic cell; one end of the AV signal line is connected to the signal generator Connect the output port of the power amplifier to the output port of the power amplifier, and connect the other end to the input port of the power amplifier; connect the test probes of the oscilloscope to the positive and negative connectors of the output signal line of the power amplifier; the positive and negative connectors are respectively connected to the graphite electrodes. Turn o...

Embodiment 3

[0038] Example 3: graphite oxide suspension 0.5 mg / ml, stripping voltage 80V, stripping frequency 40Hz, stripping time 120min

[0039] Using 30um natural flake graphite as raw material, graphite oxide was prepared by Hummers method; the obtained graphite oxide was dissolved in deionized water. At room temperature, use a magnetic stirrer to disperse for 30 minutes, prepare a 0.5 mg / ml GO suspension, and then transfer it to a cuboid electrolytic cell, and place graphite electrodes on both sides of the electrolytic cell; one end of the AV signal line is connected to the signal generator Connect the output port of the power amplifier to the output port of the power amplifier, and connect the other end to the input port of the power amplifier; connect the test probes of the oscilloscope to the positive and negative connectors of the output signal line of the power amplifier; the positive and negative connectors are respectively connected to the graphite electrodes. Turn on the powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com