Method for preparing ZSM-5 molecular sieve without template agent

A ZSM-5, template-free technology, applied in the field of molecular sieves, can solve the problems of high pressure, high crystallization temperature, and high production cost, and achieve the effects of high crystallinity, simplified process, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

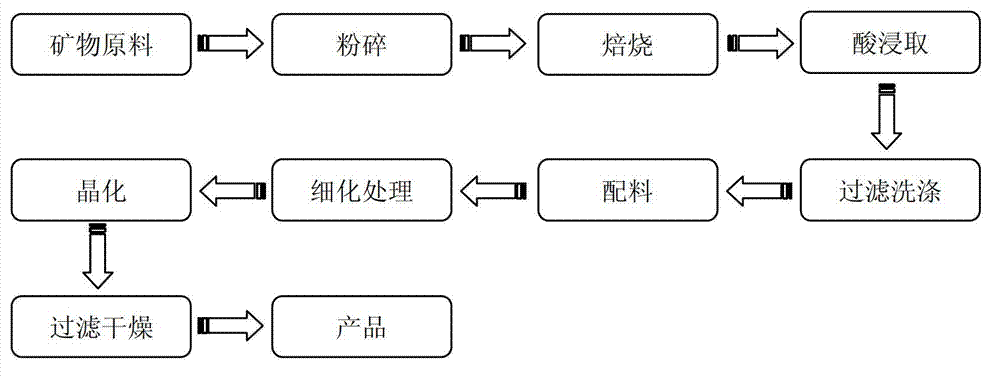

[0048] The main operation steps of this embodiment are as follows:

[0049] (1) Pulverize (ball mill) the gangue to d50=0.64μm, and then roast at 900°C for 2 hours.

[0050] (2) The roasted HCl solution with a concentration of 6mol / L, a solid-to-liquid ratio of 1:5, leached for 2 hours at 80°C, filtered and washed, and the obtained residual solid precursor SiO 2 / Al 2 o 3 The molar ratio was 21.

[0051] (3) Make a slurry mixture according to the following mass ratio, and acid-treat coal gangue (SiO 2 / Al 2 o 3 =21, with SiO 2 Molar ratio): NaOH: deionized water = 1: 0.15: 10, and then uniform refinement treatment.

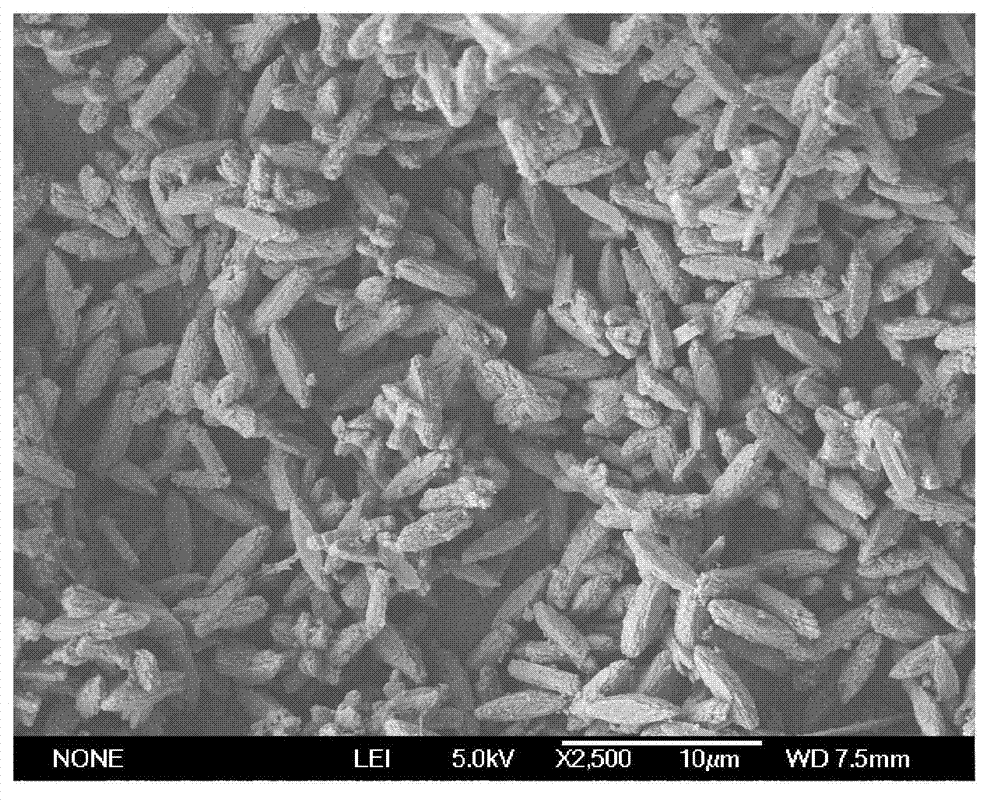

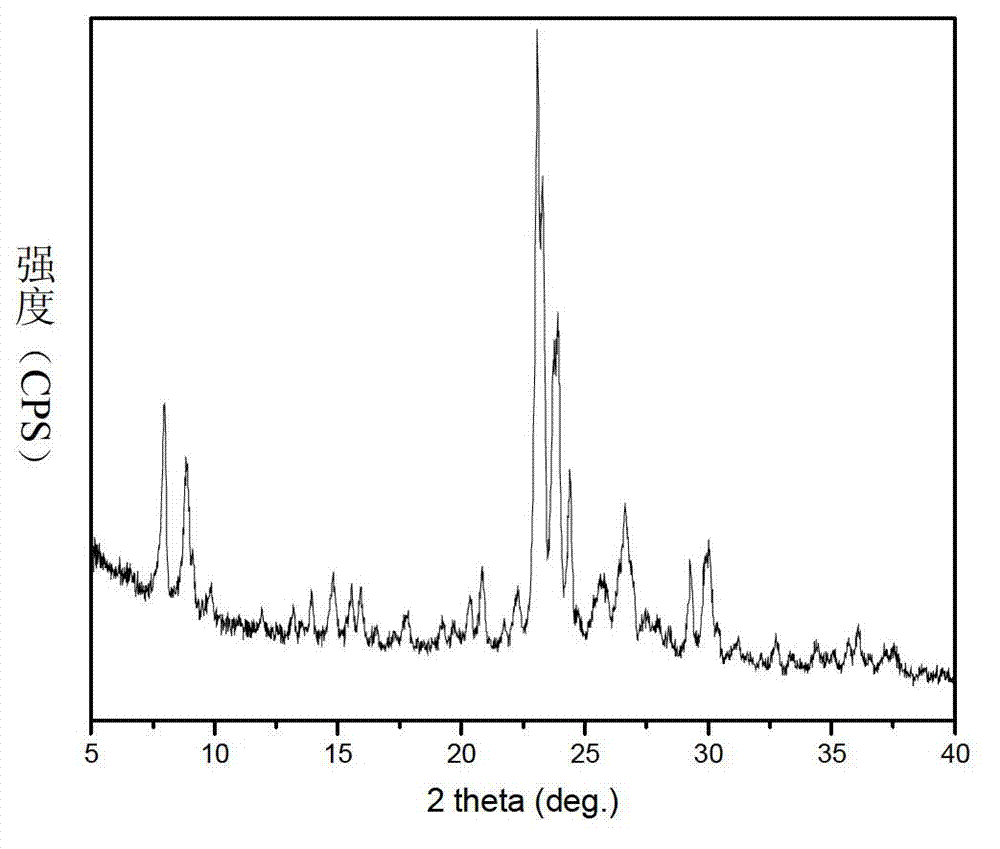

[0052] (4) Put the homogeneously refined slurry in a reactor for crystallization reaction at 190°C for 72 hours. Filter and dry at 100°C for 12 hours to obtain ZSM-5. XRD results showed that the product was ZSM-5 phase with high crystallinity.

Embodiment 2

[0054] The main operation steps of this embodiment are as follows:

[0055] (1) Pulverize (ball mill) the coal gangue to d50=0.64μm, and then roast at 800°C for 2 hours.

[0056] (2) The roasted HCl solution with a concentration of 6mol / L, a solid-to-liquid ratio of 5.0, leaching at 90°C for 1 hour, filtered and washed, and the obtained residual solid precursor SiO 2 / Al 2 o 3 The molar ratio was 16.7.

[0057] (3) Make a slurry mixture according to the following mass ratio, and acid-treat coal gangue (SiO 2 / Al 2 o 3 =16.7, as SiO 2 Molar ratio): NaOH: deionized water = 1: 0.183: 11.67, and then uniform refinement treatment.

[0058] (4) The slurry obtained in step (3) was placed in a reactor at 190°C for crystallization reaction for 72 hours. Filter and dry at 100°C for 12 hours to obtain ZSM-5. XRD results show that the diffraction peaks are typical ZSM-5 diffraction peaks, and the crystallinity is high.

Embodiment 3

[0060] The main operation steps of this embodiment are as follows:

[0061] (1) Pulverize (ball mill) the gangue to d50=1.0μm, and then roast at 900°C for 2 hours.

[0062] (2) The roasted HCl solution with a concentration of 6mol / L, a solid-to-liquid ratio of 5.0, and 80°C were leached for 3 hours, filtered and washed to obtain the residual solid precursor SiO 2 / Al 2 o 3 The molar ratio was 22.4.

[0063] (3) Make a slurry mixture according to the following mass ratio, and acid-treat coal gangue (SiO 2 / Al 2 o 3 =22.4, as SiO 2 Molar ratio): NaOH: deionized water = 1: 0.15: 15, and then uniform refinement treatment.

[0064] (4) The slurry obtained in step (3) was placed in a reactor at 190°C for crystallization reaction for 72 hours. Filter and dry at 100°C for 12 hours to obtain ZSM-5. XRD results show that the diffraction peaks are typical ZSM-5 diffraction peaks, and the crystallinity is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com