Screening method and application of strain for producing 1,3-propanediol

A screening method and strain technology, applied in the field of 1,3-propanediol, can solve problems such as hidden dangers of biological safety, and achieve the effects of reducing production costs, simple operation, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

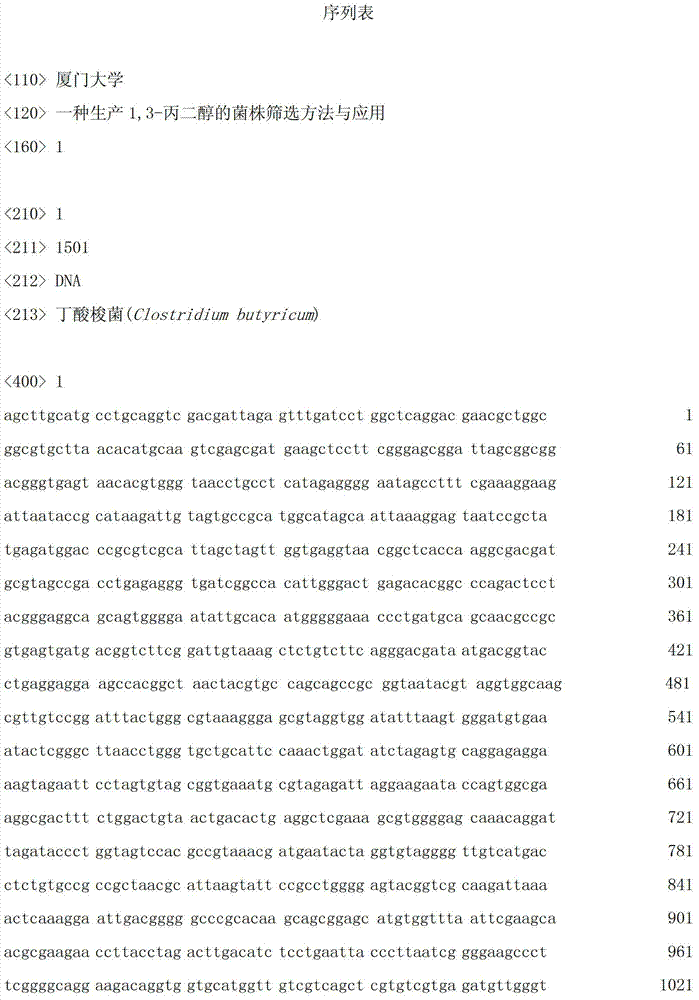

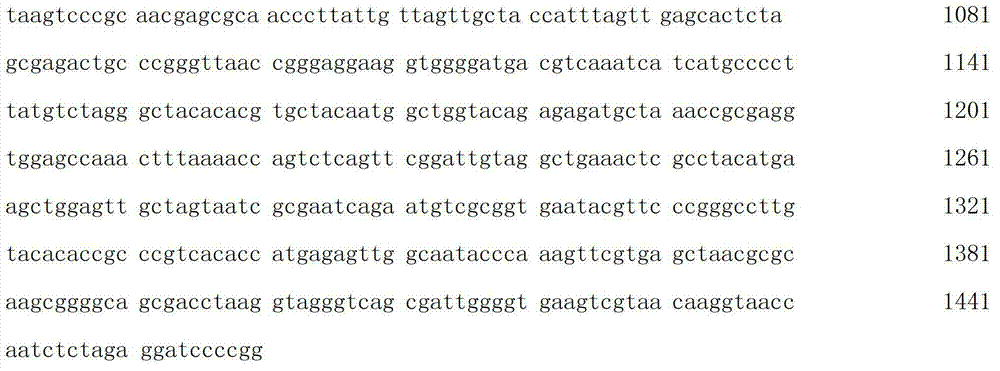

Image

Examples

Embodiment 1

[0036] 1. Isolation and purification of strains:

[0037] 1) Take 1g of each collected sample, add it to 9mL cabbage juice, and culture for 24 hours at 37°C under sealed enrichment.

[0038] 2) Place the above-mentioned culture solution in a water bath at 80°C for 10 minutes to kill non-spore bacteria, transfer it to the Clostridium proliferation liquid medium, and culture it anaerobically at 37°C for 24 hours.

[0039] 3) Put the above-mentioned culture solution in a water bath at 80°C for 10 minutes, transfer it to the fermentation medium, and cultivate it for anaerobic selective enrichment at 37°C for 24 hours. The fermentation products were analyzed by high performance liquid chromatography, and the positive bacteria capable of producing 1,3-propanediol were selected for the next experiment.

[0040] 4) Gradually dilute the culture solution, adopt the high-layer agar column method (add 2% agar to the RCM medium, cover 2-3cm with paraffin oil), culture at 37°C for 24 hours...

Embodiment 2

[0057] (1) Fermentation method: 5L mechanical stirring fermenter, batch fermentation with nitrogen

[0058] (2) Strains: Clostridium butyricum Gen0

[0059] (3) Medium:

[0060] Seed medium ( / L) is: glycerol, 20g; K 2 HPO 4 ·3H 2 O, 4.45g; KH 2 PO 4 , 1.3g; (NH 4 ) 2 SO 4 , 2g; MgSO 4 ·7H 2 O, 0.2g; CaCl 2 2H 2 O, 0.02g; yeast powder, 1g; trace element solution, 1mL; Fe solution, 1mL; natural pH.

[0061] The fermentation medium ( / L) is: waste glycerol (glycerol content is about 90% w / w); KH 2 PO 4 , 1.2g; (NH 4 ) 2 SO 4 , 2g; MgSO 4 ·7H 2 O, 0.2g; CaCl 2 2H 2 O, 0.02g; yeast powder, 1g; trace element solution, 1mL; Fe solution, 1mL; pH 7.0.

[0062] The Fe solution ( / L) is: FeSO 4 ·7H 2 O, 5 g; HCl (37%), 4 mL.

[0063] The trace element solution ( / L) is: ZnCl 2 , 0.07g; MnCl 2 4H 2 O, 0.1g; H 3 BO 3 , 0.06g; CoCl 2 ·6H 2 O, 0.2g; CuCl 2 2H 2 O, 0.02g; NiCl 2 ·6H 2 O, 0.025g; Na 2 MoO 4 2H 2 O, 0.035 g; HCl (37%), 0.9 mL.

[0064] (4) F...

Embodiment 3

[0071] (1) Fermentation method: 5L mechanical stirring fermenter, batch fermentation with nitrogen gas.

[0072] (2) Strains: Clostridium butyricum Gen100.

[0073] (3) Culture medium: the same as in Example 2.

[0074] (4) Fermentation process:

[0075] Seed culture: with embodiment 2.

[0076] Seed expansion cultivation: with embodiment 2.

[0077] 5L fermenter culture: Inoculate the expanded seed liquid with 10% inoculum in 2L fermentation medium containing 70g / L waste glycerol, control the fermentation temperature at 37°C, and use a pH concentration of 4mol / L NaOH solution The automatic adjustment is maintained at 7.0, the stirring speed is 150rpm, and nitrogen (0.1vvm) is passed into the fermenter during the fermentation process to maintain the anaerobic condition of the fermentation system. When the pH of the fermentation broth rises significantly (higher than 7.0), the fermentation is terminated, and the fermentation time is 20 hours.

[0078] (5) Fermentation resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com