Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as increased environmental protection pressure, increased ammonia nitrogen wastewater discharge, and increased post-treatment costs, reducing production costs and improving The effect of production efficiency and environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

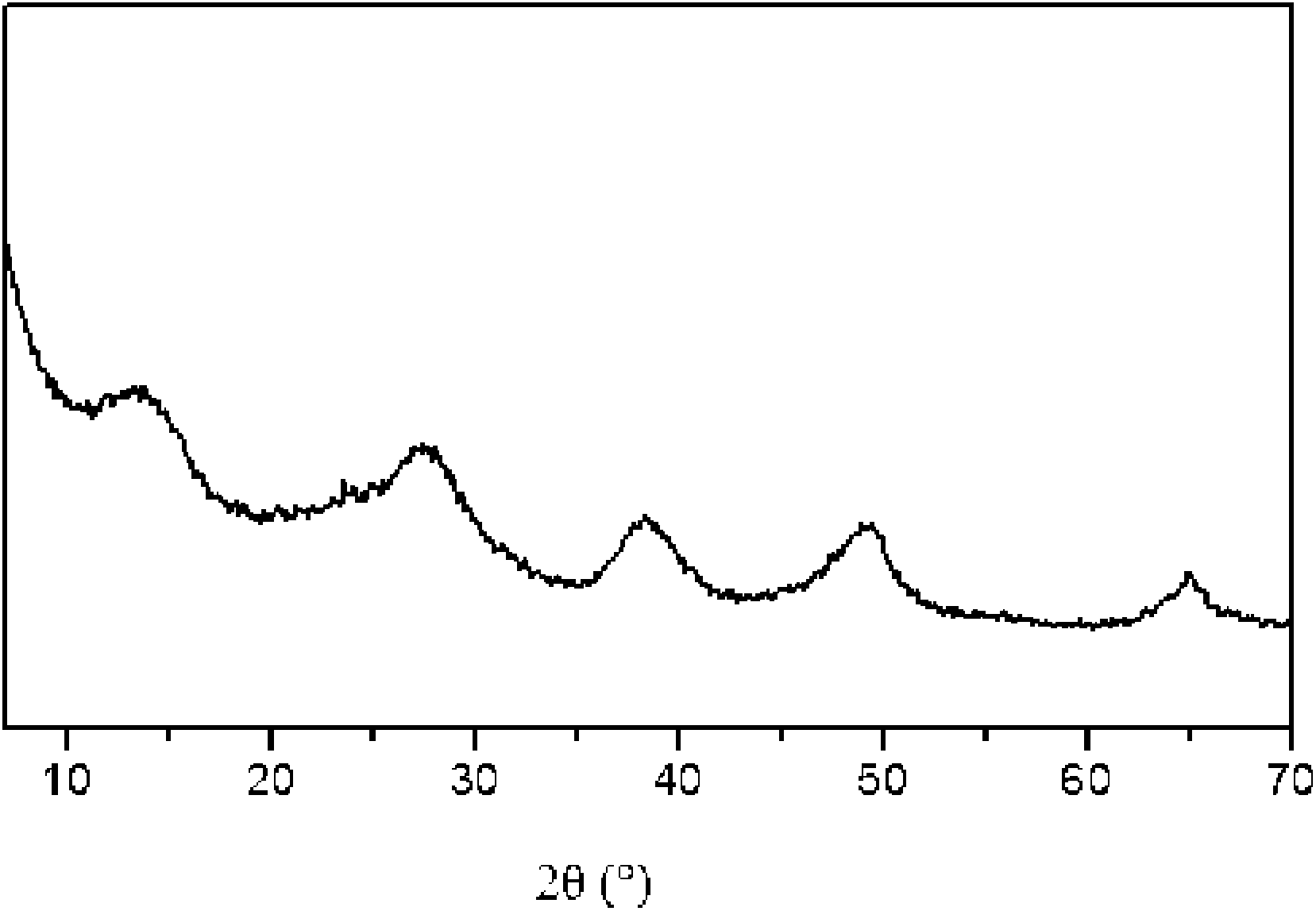

Image

Examples

preparation example Construction

[0042] In the process of preparing the mesoporous silica-alumina material, the non-ion-exchanged mesoporous silica-alumina material may be various mesoporous silica-alumina materials without any ion exchange commonly used in the art. The non-ion-exchanged mesoporous silica-alumina material can be prepared according to conventional methods, and the preparation method can include, for example, neutralizing the aluminum source and alkali solution at room temperature to 85°C to form a gel, and the final pH of the gel is 7 -11; then follow SiO 2 :Al 2 o 3 =1:(0.6-9) weight ratio Add silicon source, age at room temperature to 90°C for 1-10 hours, and then filter. In the present invention, the silica-alumina precipitate obtained after the filtration can be directly used as the non-ion-exchanged mesoporous silica-alumina material, or it can be used as the ion-free mesoporous silica-alumina material after being dried and / or calcined. Exchanged mesoporous silica-alumina materials.

...

Embodiment 1

[0104] This example is used to illustrate the catalytic cracking catalyst provided by the present invention.

[0105] (1) Preparation of mesoporous silicon-aluminum materials

[0106] The concentration is 90g Al 2 o 3 / L Al 2 (SO 4 ) 3 solution and concentration is 102g Al 2 o 3 / L, NaAlO with a caustic ratio of 1.7 2 The solution is fed into the continuous gelling kettle in parallel, the effective volume of the gelling kettle is 200ml, Al 2 (SO 4 ) 3 The flow rate of the solution is 20ml / min, adjust NaAlO 2 The flow rate keeps the gelling pH value at 9, and the gelling temperature is 55°C; collect 300ml of the gelled slurry, and add 127ml of SiO with a content of 60g under stirring conditions 2 / L of water glass aqueous solution, heated to 80°C for aging for 4 hours, and then filtered.

[0107] The silicon-aluminum precipitate obtained after filtration is mixed with water at a weight ratio of 1:12 for beating, and then the hydrochloric acid solution is added into ...

Embodiment 2-7

[0111] This example is used to illustrate the catalytic cracking catalyst provided by the present invention.

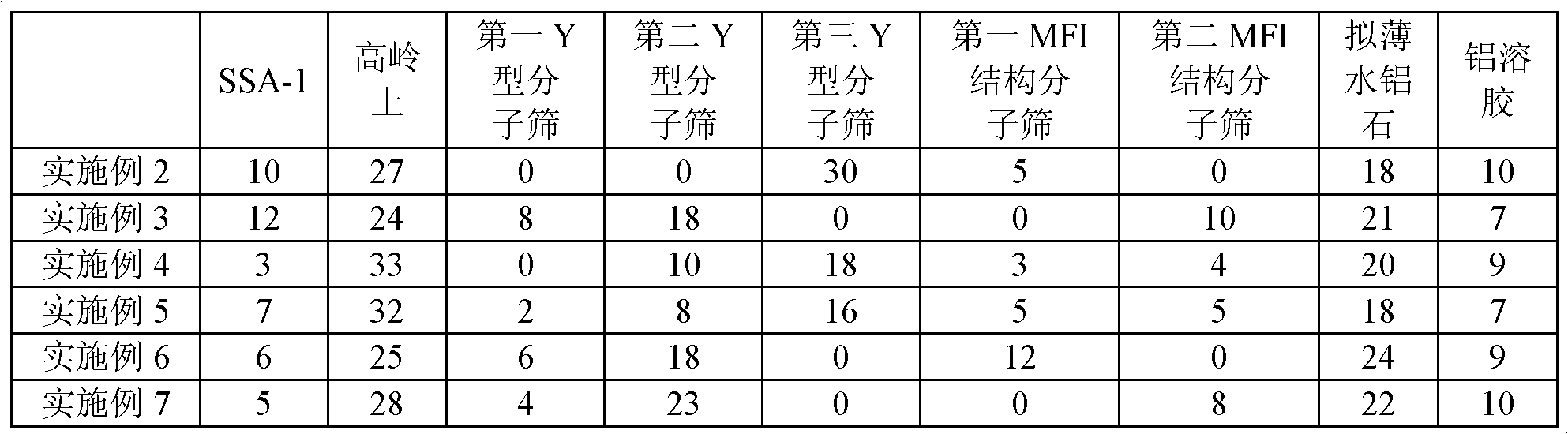

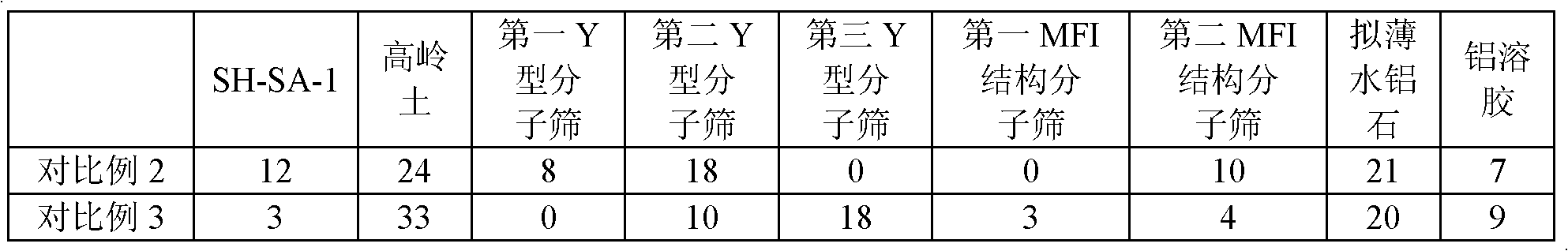

[0112] Prepare catalytic cracking catalyst according to the method of embodiment 1 respectively, difference is, in step (2), mesoporous silica-alumina material, kaolin, described first Y-type molecular sieve, described second Y-type molecular sieve, described The dosages of the third Y-type molecular sieve, the first MFI structure molecular sieve, the second MFI structure molecular sieve, pseudo-boehmite and aluminum sol on a dry basis are shown in Table 2 below. The feed amounts are all in parts by weight, so as to prepare catalytic cracking catalysts C2-C7 respectively.

[0113] Table 2

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com