High-efficient epoxy resin adhesive and preparation method and applications thereof.

A technology of epoxy resin glue and epoxy resin, which is applied in the direction of epoxy resin glue, adhesives, adhesive additives, etc., can solve the problem of high cohesion, high bonding strength, and epoxy resin adhesives that cannot meet the requirements of high adhesives. Requirements and other issues to achieve the effect of improving compression resistance, good bonding performance, and reducing curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

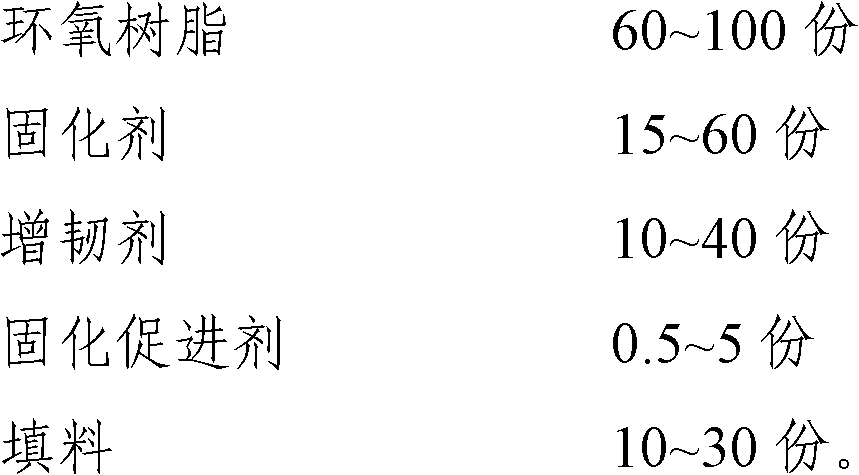

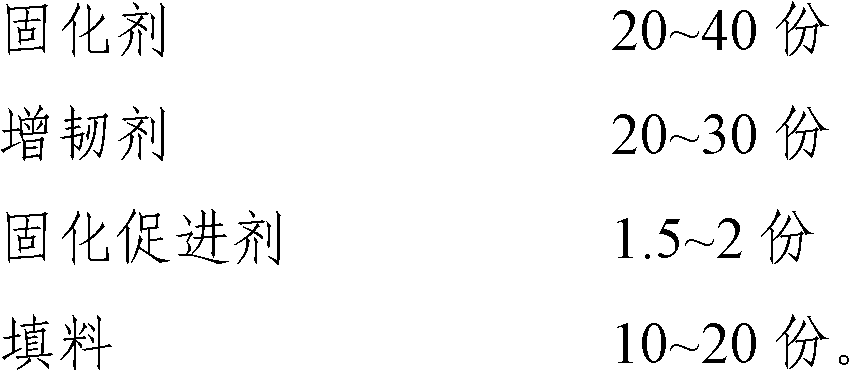

Method used

Image

Examples

Embodiment 1

[0033] Get 48.0g bisphenol A type glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Blue Star Chemical New Material Co., Ltd., epoxy value is 0.48-0.54), 12.0g glycidyl ester epoxy resin TDE-86 (purchased from Tianjin Jingdong Chemical Composite Material Co., Ltd., epoxy value 0.88) mixed evenly, then added 24.0g nonylphenol, 2.0g white carbon black, 12.0g calcium carbonate, stirred evenly, then added 18.0g The mixed solution of ethylenediamine and 1.8 g of nickel chloride modified-imidazolium salt complex was continuously stirred evenly, and placed in a vacuum drying oven to remove remaining air bubbles to obtain an adhesive.

[0034] The measured tensile shear strength of the adhesive was 36.2Mpa, the tensile strength was 43.3Mpa, and the impact strength was 65kg / cm.

[0035] The adhesive is applied between the polydicyclopentadiene base plate and the polyurethane foam face plate to obtain a vehicle composite material plate.

[0036] The measured peel st...

Embodiment 2

[0038] Get 66.0g bisphenol A type glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Blue Star Chemical New Material Co., Ltd., epoxy value 0.48-0.54), 34.0g glycidyl ester epoxy resin Resin TDE-86 (purchased from Tianjin Jingdong Chemical Composite Material Co., Ltd., epoxy value 0.88) was mixed, added 38.0g polyurethane, then added 5.0g talcum powder, 18.0g silicon dioxide, stirred evenly, and then Add 58.0 g of phthalic anhydride and 5.0 g of boron trifluoride-monoethylamine, continue stirring evenly, place in a vacuum drying oven to remove remaining air bubbles, and obtain an adhesive.

[0039] The measured tensile shear strength of the adhesive is 35.1Mpa, the tensile strength is 38.3Mpa, and the impact strength is 59kg / cm.

[0040] The adhesive is applied between the polydicyclopentadiene base plate and the polyurethane foam face plate to obtain a vehicle composite material plate.

[0041] The measured peel strength is 1.5KN / m, and the bonding strengt...

Embodiment 3

[0043] Get 16.0g bisphenol A type glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Blue Star Chemical New Material Co., Ltd., epoxy value is 0.48-0.54), 64.0g glycidyl ester epoxy resin TDE-86 (purchased from Tianjin Jingdong Chemical Composite Material Co., Ltd., epoxy value 0.88) mixed, then added 12.0g polyurethane, 28.0g kaolin, stirred evenly, then added 48.0g phthalic anhydride and 5.0 g of the mixed solution of nickel chloride modified-imidazolium salt complex was continued to stir evenly, and placed in a vacuum drying oven to remove remaining air bubbles to obtain an adhesive.

[0044] The measured tensile shear strength of the adhesive was 36.5Mpa, the tensile strength was 46.2Mpa, and the impact strength was 63kg / cm.

[0045] The adhesive is applied between the polydicyclopentadiene base plate and the polyurethane foam face plate to obtain a vehicle composite material plate.

[0046] The measured peel strength is 1.3KN / m, and the bonding strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com