Method using three-bacterium mixed fermentation to convert sorbose into 2-keto-L-gulonic acid

A technology of mixed fermentation and sorbose, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problem that the associated factors cannot satisfy the growth of acid-producing bacteria and the ability of acid-producing bacteria to produce acid for a long time Keeping it in the best state, the second step mixed bacteria fermentation efficiency is difficult to be effectively improved and other problems, to achieve the effect of making up for the low fermentation efficiency, eliminating the low efficiency of acid production, and shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The strain A composed of Bacillus cereus and keto-cologronate and the strain B composed of Bacillus thuringiensis and keto-cologronate were respectively taken from the seed solution of the slant, respectively, with 5% (volume ratio) As the inoculum amount of the seed solution for three-stage continuous amplification, it was inoculated in different grades of seed culture medium (seed culture medium, peptone 0.3% by weight percentage, beef extract 0.3%, yeast extract 0.3%, corn steep liquor 0.3%) , MgSO 4 0.01%, FeSO 4 0.01%, L-sorbose 2%, pH 7.0, agar 2.5%, the balance is water; sterilize at 121°C for 20 minutes; set aside. ), cultured in shake flasks for 20 hours until the yield of guronic acid in different grades of fermentation broth was 8-10mg / ml, and transferred to the next grade;

[0022] After the above-mentioned seed liquid is expanded through three stages, get A seed liquid 2.4ml and B seed liquid 0.8ml respectively, altogether 3.2ml inserts and is equipped ...

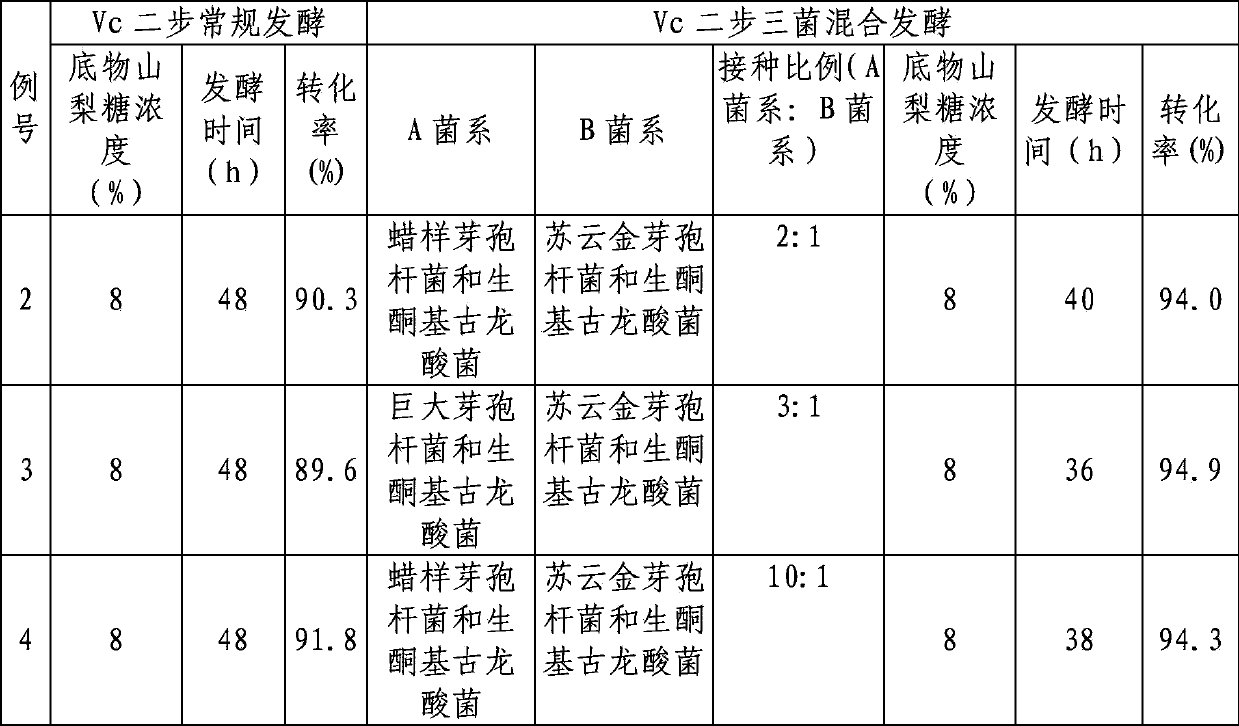

Embodiment 2-4

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com