Preparation method of ordered mesoporous carbon-tungsten coating for proton exchange membrane fuel cell stainless steel bipolar plate protection

A proton exchange membrane, fuel cell technology, applied in fuel cell parts, battery electrodes, metal material coating process, etc. , the effect of high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Dissolve 1 g of polyoxyethylene / polyoxypropylene / polyoxyethylene amphiphilic block copolymer F127 (purchased from Sigma-Aldrich) in 15.0 ml of absolute ethanol, and stir for 1 h to form a transparent solution A; At the same time, add 0.025 g of silicotungstic acid into 5 ml of absolute ethanol, and stir magnetically to obtain solution B; slowly add 5 g of ethanol solution of phenolic resin (mass fraction of phenolic resin 20%) in solution A, and stir for 10 min; then Add solution B to solution A drop by drop, stir for 1 h to mix evenly, so as to obtain light yellow transparent carbon-tungsten solution;

[0040] (2) Add the previously prepared carbon-tungsten solution on the stainless steel sheet drop by drop on the desktop glue homogenizer. s, the glue homogenization time is 60 s, repeat the glue dropping and glue homogenization process 5 times;

[0041] (3) The stainless steel sheet coated with the solution was transferred to an oven, the solvent was evaporated at...

Embodiment 2

[0045] In this example, except that the dosage of silicotungstic acid was changed to 0.05g, the dispensing speed was selected as 800 rpm / s, the dispensing time was 10 s, the dispensing speed was selected as 3000 rpm, the dispensing time was 45 s, and the temperature was kept at 350 °C for 4 h ; All the other contents are the same as in Example 1.

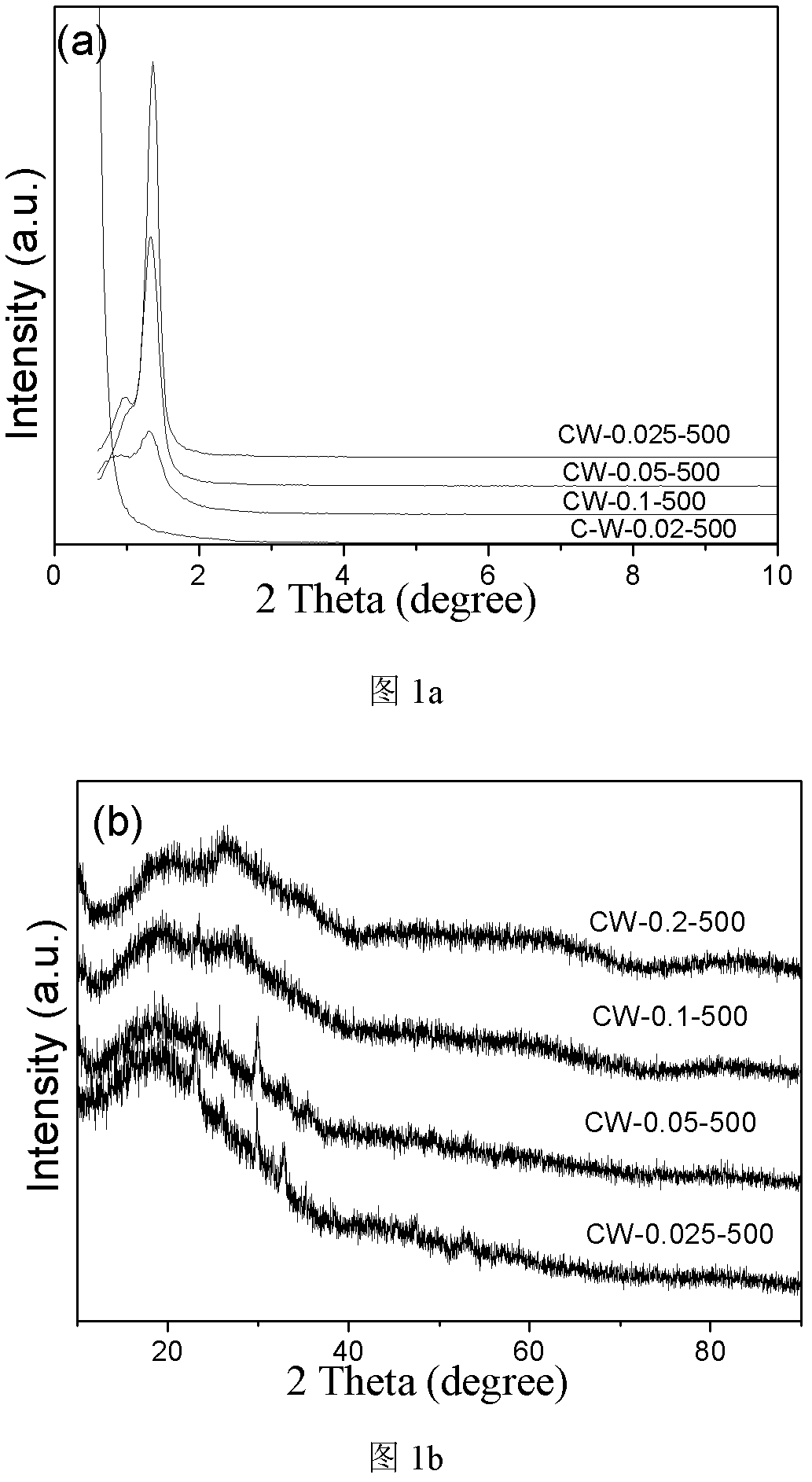

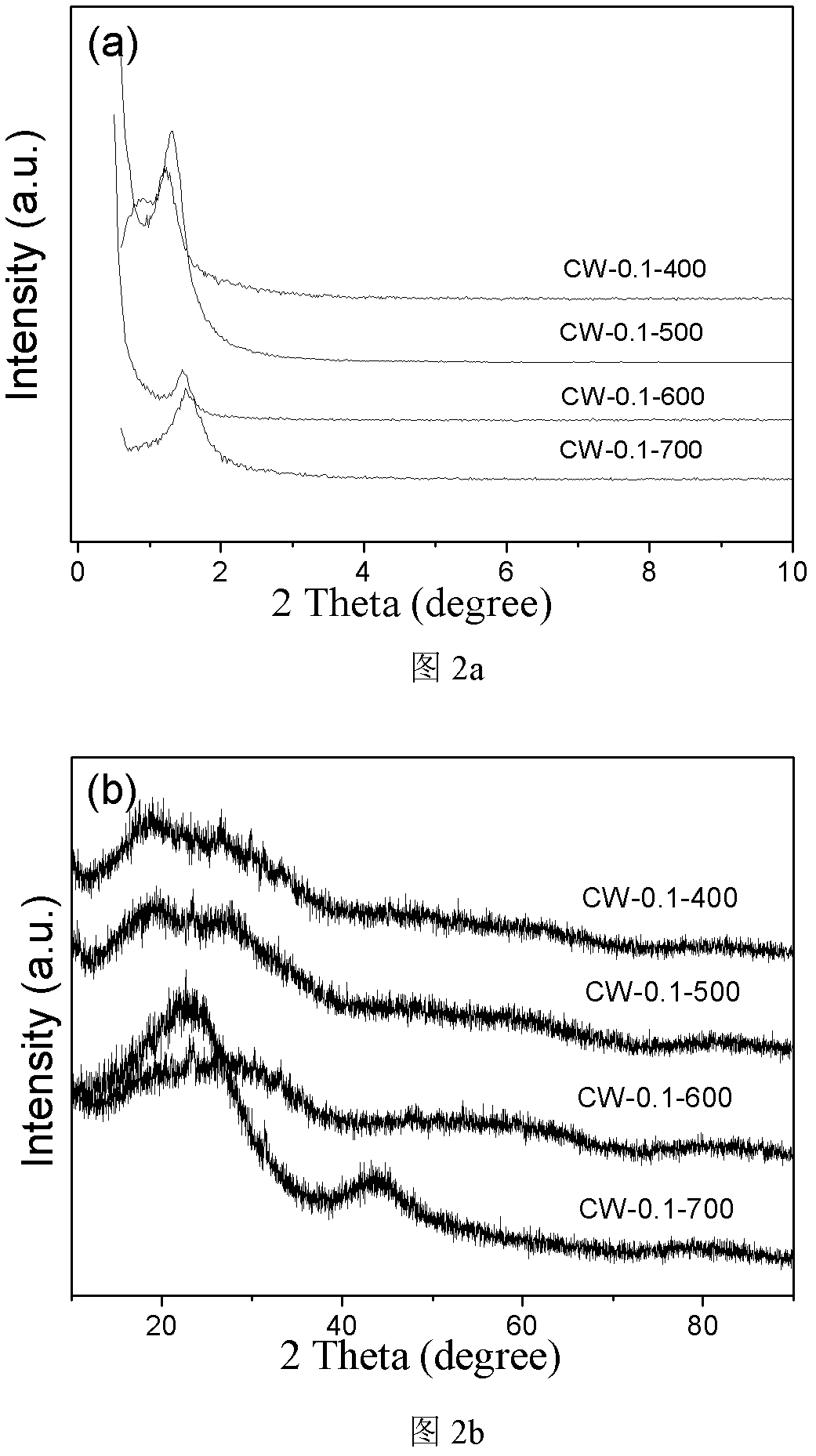

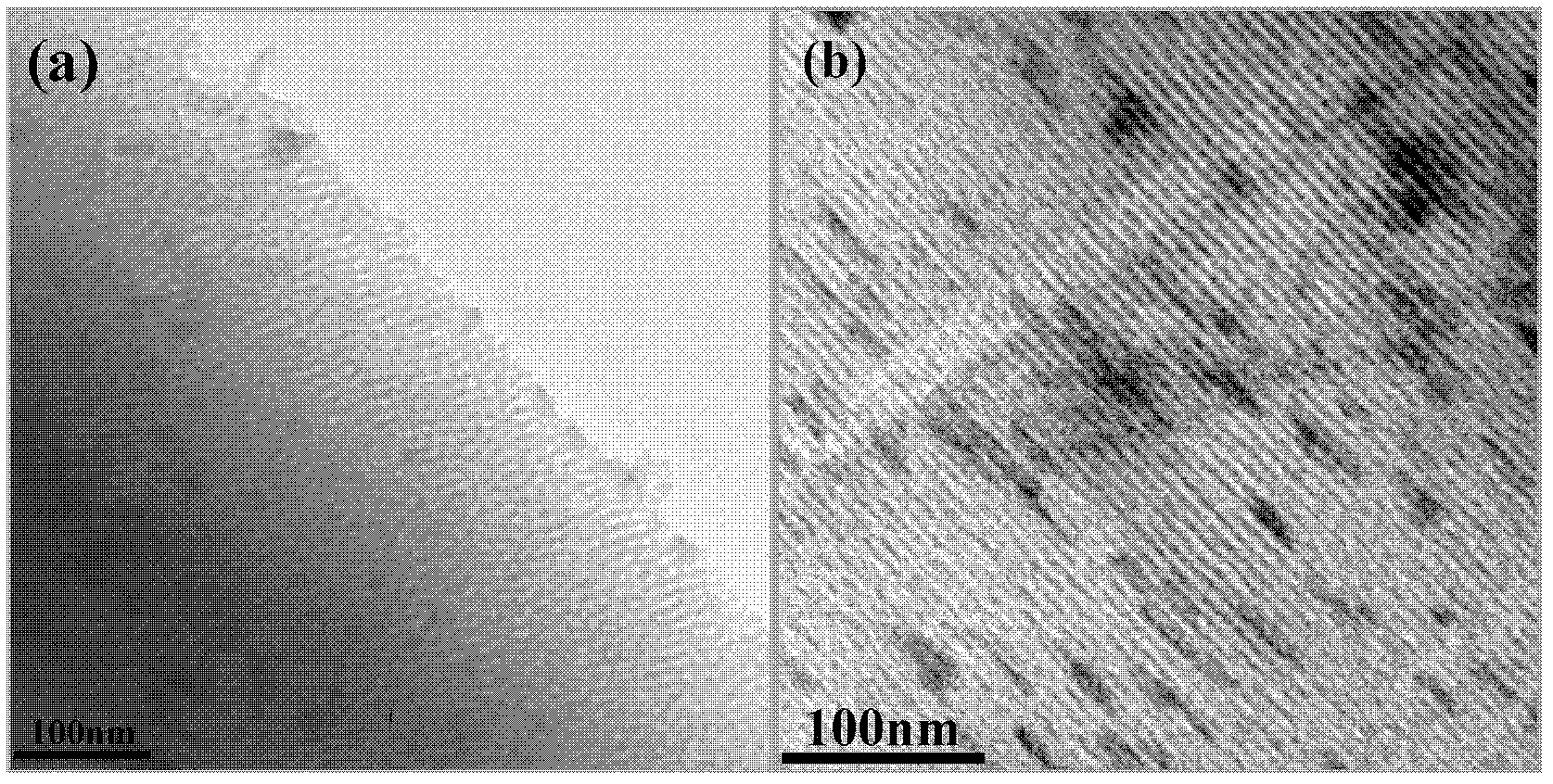

[0046] The CW-0.05-500 coating is obtained, the metal tungsten salt forms nano-short rods during the carbonization process, and is highly dispersed in the carbon matrix, which ensures that the ordered mesoporous structure of the coating is not destroyed (see figure 1 -a and image 3 -b), see Table 1 for specific structural data. at 0.5 M H 2 SO 4 The data of the Tafel test under the system are shown in Table 2. It can be seen from Table 2 that compared with the uncoated 304 stainless steel, the self-corrosion potential of the CW-0.05-500 coating is positively shifted by about 500 mV, the corrosion current density is reduced by ...

Embodiment 3

[0048] In this example, except that the dosage of silicotungstic acid is changed to 0.1g, the glue dropping speed is selected as 500 rpm, and the temperature is kept at 350°C for 5 hours; the rest of the content is the same as that of Example 1.

[0049] To obtain CW-0.1-500 coating, the metal tungsten salt forms nanorods during carbonization and is highly dispersed in the carbon matrix, which ensures that the ordered mesoporous structure of the coating is not destroyed (see figure 1 -a and image 3 -c), see Table 1 for specific structural data. at 0.5 M H 2 SO 4 The data of the Tafel test under the system are shown in Table 2. It can be seen from Table 2 that compared with the uncoated 304 stainless steel, the self-corrosion potential of the CW-0.1-500 coating is positively shifted by about 500 mV, the corrosion current density decreases by two orders of magnitude.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com