Crisp chips of carmine radish and preparation method of crisp chips

The technology of rouge radish and radish chips is applied in the field of preparation of fruit and vegetable chips, which can solve the problems such as no research report on rouge radish chips, and achieve the effects of enriching the market, broadening the market, and regularizing the shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention first optimizes the preparation process of the rouge radish chips. The preparation process of rouge radish chips is as follows: select rouge radish with regular shape, tender meat, dense tissue, and uniform pigment distribution, remove fibrous roots and tail roots, slice (thickness is 2-4mm), and put it in hot water at a certain temperature. Bleaching for a certain period of time, then marinating in a pickling solution for a certain period of time at a certain temperature, then placing it in a fermentation solution for fermentation at a certain temperature for a certain period of time, and finally drying to obtain rouge radish chips (non-fried process); Alternatively, the dried rouge radish slices are fried and deoiled to prepare rouge radish chips (fried process).

[0034] 1. Optimization of blanching process

[0035] 1. Optimization of blanching temperature

[0036] Take five beakers, fill them with 100mL water, heat them to different temperatures (80...

Embodiment 1

[0160] Embodiment 1, the preparation of rouge radish chips (non-fried process)

[0161] a. Material selection: Select rouge radish with regular shape, tender meat, dense tissue and even distribution of pigment, remove fibrous roots and tail roots, and cut into slices with a thickness of 3mm;

[0162] b. Blanching: putting the rouge radish slices prepared in step a into 95°C hot water for 15 minutes;

[0163] c. Pickling: put the rouge radish slices blanched in step b in a salt solution with a concentration of 0.16g / mL and marinate at 30°C for 1 hour, and add 1L of salt solution for every 1000g rouge radish slices;

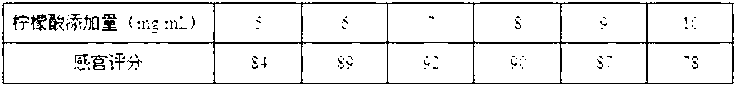

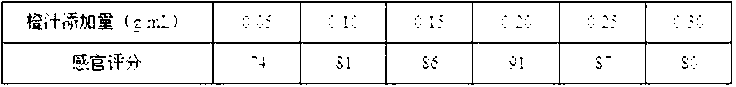

[0164] d. Fermentation: Put the pickled rouge radish slices in step c to ferment for 2 hours at 30°C in a fermented liquid prepared from fermented rice water, white sugar, white vinegar, ascorbic acid, citric acid, orange juice and water, wherein the fermented fermented water The added amount is 0.02g / mL, the added amount of white sugar is 0.3g / mL, the added...

Embodiment 2

[0167] Embodiment 2, the preparation of rouge radish chips (fried process)

[0168] a. Material selection and slicing: select rouge radishes with regular shape, tender meat, dense tissue, and uniform pigment distribution, remove fibrous roots and tail roots, and cut into slices with a thickness of 3mm;

[0169] b. Blanching: putting the rouge radish slices prepared in step a into 95°C hot water for 15 minutes;

[0170] c. Pickling: put the rouge radish slices blanched in step b in a salt solution with a concentration of 0.16g / mL and marinate at 30°C for 1 hour, and add 1L of salt solution for every 1000g rouge radish slices;

[0171] d. Fermentation: Put the pickled rouge radish slices in step c to ferment for 2 hours at 30°C in a fermented liquid prepared from fermented rice water, white sugar, white vinegar, ascorbic acid, citric acid, orange juice and water, wherein the fermented fermented water The added amount is 0.02g / mL, the added amount of white sugar is 0.3g / mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com