Protective cover of lifesaving raft special for large ship seagoing tanker and manufacturing method thereof

A technology for ocean-going oil tankers and life rafts, which is applied to life rafts, chemical instruments and methods, and synthetic resin layered products. It can solve the problems of high maintenance costs, achieve high dimensional accuracy, low energy consumption, and improve production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

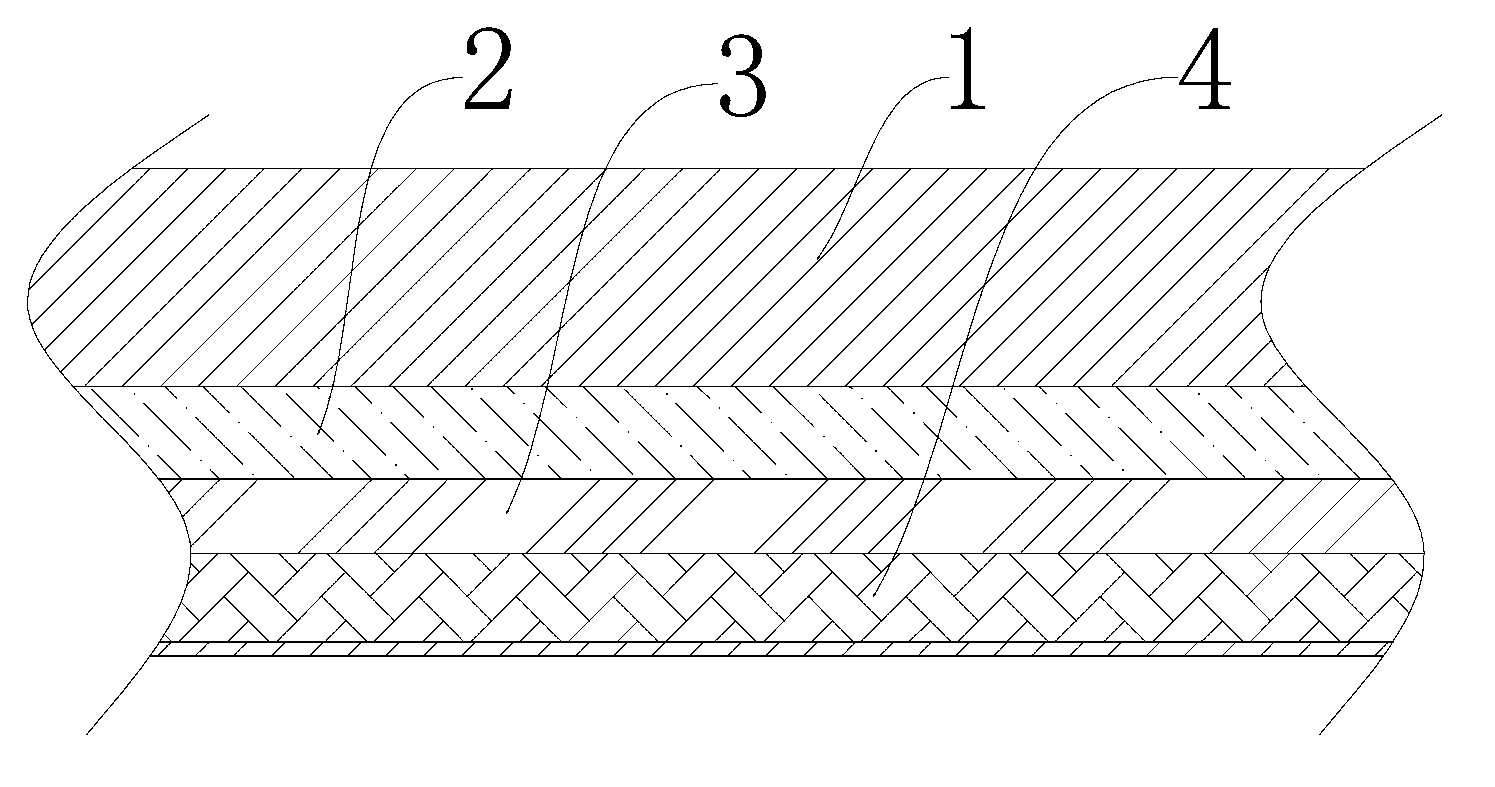

[0011] Such as figure 1 As shown, the special liferaft shield for large-scale ocean-going oil tankers described in this embodiment is mainly composed of a resin layer 1. At the bottom of the resin layer 1, a first alkali-free glass fiber chopped strand mat layer 4 is successively arranged on the bottom net. Alkali glass fiber sandwich composite mat layer 3, and the second alkali-free glass fiber chopped mat layer 2.

[0012] The first alkali-free glass fiber chopped strand mat layer 4 is an alkali-free glass fiber 300g chopped strand mat; the alkali-free glass fiber sandwich composite mat layer 3 is an alkali-free glass fiber 1380g sandwich composite mat; the second alkali-free glass fiber The fiber chopped strand mat layer 2 is 450g of alkali-free glass fiber chopped strand mat.

[0013] The manufacturing method of the special life raft shield for large-scale ocean-going oil tankers is to cut alkali-free glass fiber chopped strand mat and alkali-free glass fiber sandwich composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com